Air heating using convection ovens has one significant drawback. The efficiency of heating largely determines the configuration of the room. The presence of interior partitions and other obstacles in the way of convection flows significantly worsens the uniformity of heating. To heat rooms located on another floor, you have to connect air ducts and run them throughout the house, which is not always convenient and requires serious additional costs.

The Buleryan stove with a water circuit is the optimal solution for heating a multi-storey residential building with several rooms. The unit is connected to an existing heating system. Heat begins to flow into the rooms almost immediately after kindling.

The principle of operation of the furnace Breneran Aquaten

Heating boilers Buleryan (Breneran) with a water circuit, in their design, are not much different from traditional equipment using the principle of air convection. The design provides for pipes surrounding the combustion chamber. The principle of gas generation or pyrolysis is used. The main difference is that instead of air, a liquid coolant circulates through the pipes.Breneran long-burning boilers with a water circuit operate as follows:

- A special collector is mounted on the convection pipes from above and below.

- On the lower manifold there is a return outlet, on the upper one for supplying the coolant.

- During the combustion, the heat carrier heats up, which creates pressure in the heating system, which allows for natural circulation, as well as the rise of the liquid to a height of 8 m. The heat carrier flows through pipes to the heating devices located in the rooms.

- After cooling, the coolant returns back to the boiler to the pipes connected to the lower pressure manifold.

After heating the combustion chamber to the required temperature, the boiler is switched to the gas generation mode. During gas generation, the fuel does not burn, but literally smolders, which increases autonomous operation from one tab, while maintaining the heat transfer coefficient at the level of conventional wood burning.

Canadian furnaces "potbelly stoves" of long burning Breneran, were developed to work on wood. It is allowed to use peat and wood briquettes, as well as wood waste, but at the same time, energy efficiency and heat transfer indicators fall somewhat.

Types of stoves Aqua Breneran

The plant manufacturer of boilers Aquaten Breneran, CJSC Laoterm, has developed and produced several basic modifications of gas-generating furnaces with a water circuit. The advantage of the models is high efficiency, the presence of an electric heating element, which allows you to continue heating the room after all the solid fuel has burned out.If necessary, the stove is understaffed with an indirect heating boiler that provides the required amount of hot water.

The model range of Russian-made solid fuel gas-generating furnaces Breneran Aquaten is represented by the following modifications:

When choosing a long-burning wood-burning heating stove with a Breneran Aquaten water circuit, pay attention to its performance. The technical documentation indicates the volume of the coolant and the actual heated area.

How much is Breneran Aquaten

The cost of the Breneran Aquaten stove is slightly higher than that of models that do not have a water jacket and depends on the type of model and its power.- AOTV 06 - will cost 16,200 rubles.

- AOTV 11 - for this model you will have to pay 23,800 rubles.

- AOTV 14 - the cost will be 27,400 rubles.

- AOTV 16 and 19 - for semi-industrial models you will have to pay 45 and 55 thousand rubles. respectively.

Advantages of water heating from Breneran

Breneran gas-generating furnaces have several significant advantages over analogues using the principle of air heating.- Rooms are heated by standard heating radiators and not by air circulation. Therefore, the models are suitable for heating one- and two-story individual residential buildings, moreover, there is no need for additional equipment in the form of air ducts.

- Installation in a house without a basement is allowed. With proper installation and regular maintenance of the stove, there is no chance of smoke entering the room.

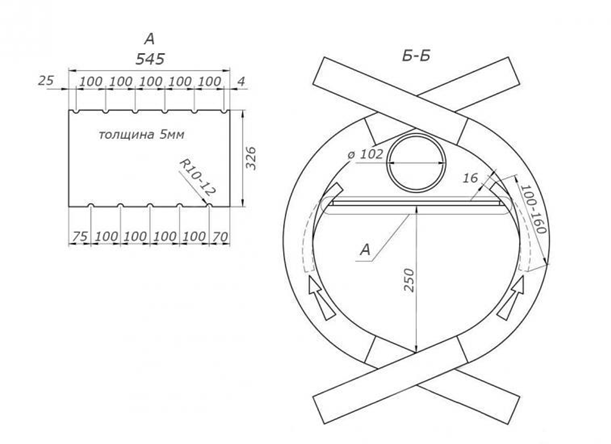

- The Breneran Aquaten stove is welded from steel, 2-3 mm thick for the outer casing, 5 mm for the combustion chamber. In the manufacture of heat-resistant alloys are used, which significantly increases the life of the device.

- Possibility of connection to the heating system of almost any type. The main thing is to correctly select and calculate the performance of the furnace. Breneran feels equally good when connected to a heating system with natural and forced circulation.

- Easy installation. It makes sense to install a modification of the Breneran furnace with the connection of a water heating system, if there is no desire and opportunity to connect gas heating. The Aquaten model provides maximum ease of use. If necessary, it can work in anti-freeze mode. Electric heater will heat the coolant to the required temperature.

Disadvantages of water boilers Breneran

Of course, Breneran Aquaten boilers have disadvantages, but since they are insignificant and inferior to the advantages, almost nothing is reported about them either on construction forums or on other sites. But judging by the few comments that we managed to find, the furnace problems are as follows:- It will not work to use the Breneran Aquaten model without water. The design is provided exclusively for liquid cooling.

- Aquaten has inherent disadvantages of all gas generator models. The characteristics and performance are affected by the quality of the fuel, errors in the installation of the chimney pipe.

Features and installation methods Breneran Aquaten

As already noted, the design of the stove allows you to use any options for connecting water heating. It is allowed to operate the device in systems with forced and natural circulation of the coolant.When carrying out installation work, the PPB standards regarding the installation of the furnace and the connection of the smoke exhaust system, the features of closed and open systems are taken into account. The performance and heat transfer is affected by the type of boiler piping and the heat carrier used.

fire safety requirements

The manufacturer ZAO Laoterm received a fire safety certificate for the Aqua Breneran furnace with a water circuit. This indicates that the boiler is protected from accidental ignition, and if used correctly, the likelihood of a fire is minimized.Installation in a residential area is carried out taking into account the existing PPB rules for TT boilers:

- The furnace is mounted on a solid non-combustible base. For models AOTV 14, 16 and 19, a concrete base is required.

- On the side of the firebox, the floor is covered with a sheet of steel, at least 1.25 m in length.

- The distance to the plastered walls is at least 1 m, with additional insulation 0.8 m.

- The dimensions of the room for installing the furnace are at least 12 m².

- The boiler room must have a ventilation duct and good natural air ventilation.

- Automata to turn off the heating element and circulation equipment are installed in adjacent rooms.

The presence of a safety group for the solid fuel pyrolysis boiler Breneran Aquaten (including a safety, air valve, pressure gauge, expansion membrane tank) is mandatory. Commissioning, in the absence of safety fittings, is prohibited.

Installing a smoke exhaust system

The rules for installing a chimney are described in detail in. According to the norms, the height and diameter are calculated depending on the performance of the furnace. During the installation of the chimney, the manufacturer's recommendations are closely followed:- Distances to structural nodes, beams and rafters are calculated depending on the material of the chimney. For a brick and ceramic chimney with insulation, a fire gap of at least 13 cm, without insulation 25 cm.

- The height of the chimney should be from 5 to 9 m, depending on the stove model.

- A deflector is installed on the chimney head to improve traction characteristics.

Detailed information regarding pipe selection and PPB standards is located in.

Connection to a natural circulation system

The heating system with natural circulation of the coolant is the most popular, due to the ease of installation and the absence of a large number of additional components. There are several rules associated with installation:- The oven is located at least 0.5 m below the radiators.

- The pipes are placed at an angle - the slope is made towards the circulation of the coolant.

- An open expansion tank is mounted at the highest point of the heating system. The capacity of the tank is chosen depending on the total volume of the coolant, in a proportion of 10%. The correct installation of an open-type expansion tank is carried out on the return line of the heating system. If the container is installed in an unheated attic, the thermal insulation of the device must be carried out.

- A safety group is mounted on the coolant supply.

Strict requirements are imposed on the distribution of pipes of a heating system with natural circulation, regarding compliance with the angles of inclination.

Connection to a forced circulation system

The main difference from the previous version is that a closed-type heating system needs a circulation pump. Forced circulation of the coolant has many advantages, consisting in better heat transfer, efficiency and speed of heating. The only drawback is the dependence on electricity.Installation of a heating system with forced circulation is carried out in accordance with the following recommendations:

- The circulation pump is installed on the return flow of the coolant, between the expansion tank and the boiler. It is recommended to install a temperature sensor to regulate the operation of the boiler, depending on the intensity of heating and the pressure created in a closed system.

- The connection is made with a closed-type expansion tank. Air does not enter the heating system, which has a positive effect on the duration of operation of pipes, radiators and the boiler itself.

- For uninterrupted operation of the pump, you will need to install a UPS with a built-in voltage regulator.

The maximum pressure in a closed heating system is not higher than 7 atm. Large indicators lead to a rupture of the water circuits located on the furnace. To prevent damage, be sure to install a security group.

What pipes are best for tying

Piping the boiler affects the further operation, performance and other characteristics of the heating system. The choice of material should be approached consciously. Below are the three most popular options:- Tying the heating system with steel pipes- as advantages, resistance to overheating, low linear expansion, strength and high thermal conductivity can be distinguished. The disadvantages include the complexity of installation, the need for welding.

Installation is best done before repairing the premises, so as not to spoil the finish. Another disadvantage can be considered that the diameter of the water circuit pipe will be much larger than that of polypropylene or metal-plastic, respectively, a larger furnace will be required for heating. - Polypropylene heating pipes- the material has many advantages: light weight, long service life, resistance to heat, attractive appearance, smooth inner surface.

The laying of heating pipes around the house can be done independently. This will require a soldering iron and a few construction tools. - Metal-plastic pipes- Another version of the material intended for the heating system.

The advantage of metal-plastic is: quick installation, non-corrosion, high temperature stability, plasticity. The disadvantages are the susceptibility of the pipe to "breaking".

Metal-plastic pipes are used for the installation of heating systems with forced circulation of the coolant. Approved for industrial use.

What coolant is better to fill in Breneran and the system

As a heat carrier, ordinary and distilled water, antifreeze are used. Each option has its own advantages and disadvantages:

It is quite easy to independently calculate the volume of the coolant - for calculations you will need to know the power of the furnace, the number and volume of radiators.

It is difficult to imagine any beautiful and comfortable house without high-quality heating, which creates a comfortable environment in it. Therefore, much attention is paid to the installation of heating equipment in suburban buildings. One of such modern appliances used for space heating is the water circuit stoves of the Canadian manufacturer Buleryan. They are devices equipped with heat exchangers, thanks to which, at minimal cost, evenly and very quickly, heating of all rooms in the house is ensured.

During the operation of furnaces with a water casing, their surface does not heat up at all, so the oxygen in the room is not burned out. In addition, the installation of such equipment provides the possibility of supplying the whole family with hot water at low fuel costs. It is especially advisable to install furnaces of this group in rooms where permanent residence is not provided. The efficiency of such devices is 87%.

Buleryan furnace connection diagram

Main advantages:

- The presence of pipes for the heat carrier, forming the casing-convector of the furnace.

- Hermetically sealed doors.

- The top location of the afterburner chamber.

- The flow of heated air into the afterburner compartment.

- The absence of an ash pan.

Thanks to a well-thought-out design, not only firewood, but also decomposition products are completely burned in Buleryan stoves. The increase in heat transfer of the equipment is facilitated by a special branching of the pipes. Buleryan effectively heats the water in the pipes and quickly provides heat to all connected radiators.

Heating in the house

Russia is a very large country, the borders of which lie in different climatic zones. Therefore, the problems of heating residential buildings are solved differently everywhere. Where the main type of fuel is firewood, you can often see Buleryan solid fuel boilers with an additional water circuit. They are heated exclusively with wood, and no other type of fuel can be used. After all, complex physico-chemical processes take place inside the furnace, the course of which can only be ensured by the burning of dry wood. Therefore, before choosing this particular modification, it is worth carefully calculating the cost and availability of the specified type of fuel.

How does the stove work?

It is known for certain that the idea of \u200b\u200bcreating an unusual design came up with Canadian lumberjacks. They shared their thoughts with the engineers, and the buleryan iron furnace was born. It is based on a round body, outwardly similar to a barrel, and the interior space is divided into two levels. The lower part of the barrel plays the role of a firebox where firewood is laid and where it is ignited. Here, a high temperature is formed, which contributes to the accumulation of a large amount of heat.

During the combustion of firewood, hot gases are formed, which rise and fill the space of the second part of the round barrel. Several curved pipes run through the center of the two fireboxes. The well-known method of convection allows the use of natural physical processes for the benefit of man.

Cold air enters the buleryan through pipes. In the furnace, it meets a red-hot circuit, due to which a rapidly moving air stream is formed, which breaks out at great speed, taking with it all the heat of the furnace. Without the use of fans, hot streams are injected, which very quickly warm up a small room. Thus, the Buleryan boiler with an additional circuit uses all three heating methods - convection, heat transfer and heat transfer.

Fits perfectly into the interior

The described furnace works in a special way:

- First, the firebox is slightly warmed up with wood waste.

- Then its lower throat is filled to the top with firewood.

- Solid fuels first smolder for 12 hours, during which wood gas is produced.

- It emits much more thermal energy than firewood.

- An air stream is formed, the temperature of which often reaches 120 degrees Celsius.

- It breaks out through the pipe system. Therefore, the room is quickly and efficiently heated without rebooting.

Note! In the second furnace, gas, even if there is good draft, cannot be completely burned. Therefore, for comfortable use of a stove with a water circuit, it is necessary to install a high-quality chimney. Any defect in its system will cause carbon monoxide to leak, which is very dangerous. Experts do not recommend beginners to install a chimney on their own. You can not experiment with this, it is better to immediately entrust the installation of the furnace to professionals.

Features of installation with a water circuit

Schematic diagram of use

Schematic diagram of use Until recently, almost all solid fuel stoves could not compete with central heating systems. And all because with the help of furnace equipment it was difficult to heat a large room, divided into residential sections. But after we managed to combine a conventional wood-fired boiler and a water circuit, much has changed.

Today, even a Buleryan oven can be equipped with a circulation system through which the coolant will move. New modifications received the prefix "aqua". This is how Aqua-Buleryan and Brenneran-Aquaten were born, which can be used to organize a water heating system.

In the design, the water circuit occupies almost 70% of the space of the entire combustion chamber. Therefore, the water in it heats up very quickly and evenly, and heat loss is minimal. There are no sudden temperature changes, no pressure fluctuations, so the system works properly and efficiently. The efficiency of the Buleryan furnace is comparable to the efficiency of a gas generator. Air circulation has proven itself well, so today you can often see such installations in residential buildings, and in industrial premises, and in public places.

For 12 hours, buleryan furnaces, equipped with a water circuit, produce heat with a stable temperature. This makes it possible to push back the re-laying of firewood as much as possible.

Positive Specifications

DIY model

DIY model - Modern Buleryan stoves allow you to heat a large area very quickly and evenly.

When choosing models equipped with a water circuit, heat is easy to transport even to rooms located on the second and third floors. - The buleryan oven itself has a compact size.

- It is very convenient to use, and it is easy to install, but it is better to entrust the installation of the chimney to professional stove-makers.

- Buleryan stoves consume much less fuel compared to analogue units. One maximum full load is enough for 12 hours of work.

Of course, such a list of operational benefits creates bright prospects. But for a complete picture of the features of the described design, experts recommend taking a closer look at the shortcomings of the equipment.

Negative points

Different sizes

Different sizes - It is possible to load the buleryan oven only with well-dried firewood and preferably those species that do not form resins during combustion.

- Generator gases in such a model are not fully used, less than 70% of them are burned in the second furnace, so the installation cannot be called perfect.

- When constructing a chimney, great attention must be paid to the insulation of the pipe. Otherwise, condensate will form, reducing the efficiency of the buleryan furnace.

- Since the main structural element - the body - is most often made of metal, the boiler is a source of heat. Therefore, within a meter of it, everything must have appropriate protection. If the boiler is in a corner at the junction of two walls, then you will have to think about how to protect them. Buleryan stoves should not be placed close to the walls. And this is a problem for small-sized houses. The maximum allowable distance is 20 cm.

If you want to save space, you will have to sheathe the walls with metal sheets with a height greater than the height of the body of the described device. Between the wall and the sheet, it is advisable to install a basalt insulation. In this case, the metal screen will perform two functions - to protect the walls from heating and work as an additional source of heat.

- And one more thing regarding the design features of the furnace. Dust will inevitably get into the opening of the pipes. When the buleryan furnace is fired, such a high temperature is formed in the heated channels that it burns everything in its path. As a result, the operation of the equipment is often accompanied by an unpleasant odor.

Mounting diagram

Mounting diagram In addition, positively charged ions appear in the air around the heated furnace. They instantly attract the smallest particles of dirt that enter the human body. If there are cold viruses in the room, the probability of infection of healthy people increases significantly. Therefore, rooms heated by such an installation will have to be constantly ventilated or more thoroughly cleaned, doing wet cleaning twice a day.

For those who are looking closely at such installations, experts recommend paying attention to the material from which the boiler doors are made. There are models with glass doors. They look very impressive, besides, through them you can observe the combustion of fuel. However, such an element significantly increases the cost of the buleryan furnace. The glass door has neither practicality nor aesthetics. The flame through it is visible only at the moment of kindling. Because of this, experts recommend not to overpay and purchase Buleryan stoves with a conventional metal door.

Generalization on the topic

The design of the Buleryan furnace was invented in the last century. Then she became the crown of engineering, but even today, in the age of computer technology, her popularity does not go away. Such equipment is used for organizing air heating. Hot air in a converter way spreads throughout the room, evenly warming up the space as a whole. Boilers equipped with a water circuit allow you to organize independent heating.

The main advantage that the Buleryan stove (Buller, Breneran) has is instant heating of the room with low economical fuel consumption, and then maintaining the temperature for a long time. In appearance, they resemble ordinary "potbelly stoves".

What features do bullers have

The units are installed in garden houses, garages, greenhouses, workshops, places where there is no natural gas, electricity.

They can work, providing burning in the smoldering mode up to 10-12 hours, on firewood, as well as woodworking products: dry pellets, briquettes, wood chips, paper, cardboard.

Whose invention is this

Canadian heating specialists were tasked with developing a furnace for logging teams that runs on waste material: branches, cones, sticks.

The firebox had to accommodate wood of a non-standard configuration, warm up the house in a maximum of 10-20 minutes.

According to the requirements, according to the drawings, a mobile device was created that works like a heater, safe, easy to operate.

Structure

Structurally, the buleryan slow-burning stove is an oval sealed barrel-shaped boiler. The main feature is the presence in the body of two rows of air pipes, between which metal (usually steel) strips are welded. The tubes are bent in the form of a parabola and are immersed in the furnace compartment by two thirds of the diameter.

The large round door is equipped with an air supply regulator in the form of a pipe with a smoke damper (throttle). A window with heat-resistant glass allows you to control combustion. On the throttle handle there is a scale with degrees and a movable stop limiter.

By suppressing traction, you can change the power of the buller, put out the fire, and prevent the room from cooling.

The heating chamber is divided into three parts. Below is a grate made of cast iron or steel, the upper partition in the form of a sheet with holes separates the afterburning zone. The pallet for removal of ashes is absent as superfluous. Ash particles fly out through the chimney.

On the back wall there is an exit with a damper. The gaps on it do not allow carbon monoxide gases to enter the room even with the door open. The branch pipe is connected to the chimney by a horizontal section, in which unburned pyrolysis gases cool down.

How is heating

The operation of the device is based on forced convection heat exchange. After ignition, cold air is sucked in through the lower openings of the air ducts, warms up quickly, and exits the upper opening in a hot intense flow. It is smoothly, evenly distributed throughout the room, cools, falls down. The unit, which combines three devices at once: the buleryan oven itself, the heater, the gas generator, operates in two modes:

- Kindling, which provides quick heating up to 120-150º C.

- Gasification that supports smoldering firewood at a level of 50-55º C.

Implement Properties

If we calculate the cost of gasification of the facility, the cost of preparing the necessary documentation, the economic efficiency of the Canadian invention becomes obvious. With proper maintenance, the equipment will last forever.

pros

Ease of use is due to the fact that no special training is required for operation. The closed fire system, compared to potbelly stoves and fireplaces, has the following advantages:

- the boiler does not heat up, does not “eat up” oxygen;

- two-chamber furnace and secondary air supply provide high efficiency up to 80%;

- for a system with a water circuit no permits are required;

- a long period of work on one full bookmark;

- has several standard sizes with a power of 6-35 kW;

- able to evenly warm up from 100 to 1000 m³;

- you can install the buleryan oven with your own hands.

During installation, it does not require additional strengthening of the floor. It can be transported from place to place without the inconvenience of transportation.

Minuses

The need for constant maintenance, cleaning the chimney is due to the fact that the device only runs on solid wood fuel. Moreover:

- mandatory pipe insulation is required;

- the case should be far from the wall;

- requires a lot of space;

- produces a lot of smoke at the exit;

- accumulates condensate.

In rooms separated by partitions, the heating efficiency of this type is reduced. There is a need to equip a water "shirt".

System with radiators

The design of the boiler with a water circuit is identical to the buller. Only it is not the air that heats up here, but water or antifreeze. Circulation is carried out in a natural or forced way. The liquid coolant is supplied to the upper point of the system, goes to the radiators, then along the return line to the stove, where a drain valve is installed.

When arranging such a system, the unit can be installed anywhere in the building where a chimney can be removed. It is important to observe the minimum distance to the wall - 0.5 m. For the water circuit, it is better to use reinforced polypropylene pipes that do not deform from high temperatures.

Before starting, it is necessary to carry out pressure testing and adjustment work.

Homemade boilers: is the savings real?

In order to assemble a buleryan oven with your own hands, you do not need expensive equipment and special alloys. It can be made from pipes with a diameter of 5-6 mm, sheet metal with a thickness of at least 2.5 mm, even from an old gas cylinder. The calculation of the footage, the area of blanks is carried out according to the drawings, diagrams.

Schematic representation of the device:

Buller drawings are given at the end of the article.

In the absence of the necessary tools and fixtures, you can rent at a repair shop for a small fee:

- welding machine;

- electrodes;

- grinder;

- metal scissors;

- pipe bender;

- angle grinder.

A hammer, ruler, corner, patterns, level, bars, the thickness of which is equal to the diameter of the pipe, will come in handy during the assembly process.

Step-by-step instruction

The tightness of the chamber depends on the quality of the seams, so an inexperienced craftsman should practice and check the material for weldability. As a basis, you can take the drawings of a small oven for small utility rooms and increase to the required size.

Cutting parts, forming blanks

We cut off 8 pieces from the pipe from 1 to 1.5 m long. Cut out ribbons from the sheets with semicircular notches at the ends.

We bend air ducts at an angle of approximately 80º. We bend the metal strips under the same degree.

Assembly and welding

We lay the curved convection pipes with the outlet part outward in a checkerboard pattern, starting from the back wall to the exit to the front level. For stability, we put wooden bars between them. Align the structure. We grab with spot seams at the junctions.

We weld the pallet horizontally into the inner part of the body of the body. To remove combustion products, it is better to make grate from two halves connected at an angle. First, we grab it pointwise, then we pass the entire plane with a continuous seam. We insert bent steel strips between the pipes, weld them.

First you need to make a template. We attach the cardboard to the sidewall and circle it with a pencil. Along the contour, we cut out a part from sheet metal. On it we cut out a loading window with a diameter of half the wall, shifting the center slightly below the axis. We weld a strip 40 mm wide around the perimeter of the window from the outside for a short “collar”.

We make the back wall in a similar way. A hole corresponding to the diameter of the outlet pipe is cut out in the upper part of the circle. We insert a T-shaped piece from a pipe 100 - 110 mm with a valve into it, connect it to the body. We put the walls in their places.

door

The furnace door is a short cylinder that must be accurately put on the “collar”, falling into the gap between the outer and inner rings. To increase the sealing between the rings, you need to drive an asbestos rope.

In the workpiece, we cut out a hole for the blower, weld a pipe with a throttle valve. The damper can be made by cutting through the walls of the pipe along the axes. We take a pin, weld a flat disk on it, insert it into the perforation of the pipe. From the inside, we install a semicircular heat-reflecting screen on metal spacers. We hang the door on hinges, equip the lock. We make them from scraps of a sheet. You can buy ready-made parts.

In order for the stove to be located at a sufficient height from the floor, we bend the legs from the remnants, weld them into the body in the places indicated in the drawing. After cleaning and cosmetic grinding of the surface, the structure is ready for installation.

Various types of installations are currently used for heating residential premises. One of the new types of equipment is a buleryan with a water circuit. If we talk about this equipment in more detail, then it can be described as a structure made of high-quality metal with pipes welded to it.

The main feature of this device is that it not only provides space heating, but also contributes to the emergence of the convection process. The result of this is that different parts of the room are heated evenly.

In appearance, this equipment is a boiler that runs on wood and other wood fuels. Since this installation can only work on wood materials, before purchasing it, you need to think carefully about how profitable it will be to use this equipment for heating in your home. In large cities, firewood is a fairly expensive type of fuel. In order to purchase it in the right quantity, you need to specially go to a store selling such wood material.

Principle of operation

This oven works according to the well-known law of physics. The basic principle is that hot steam tends to rise, while cold vapor descends. Thanks to this, even small-sized furnaces equipped with a water jacket are able to provide heating up to 5 cu. m. of air. In this case, the equipment does not heat up. That is, the burnout of oxygen in the room is excluded.

Buleryan experts refer to the number of stoves that are economical, because by using it in a home, you can reduce fuel costs. This is ensured due to the presence in its design of a special afterburner chamber. It burns all the gas that was formed during the combustion process. The casing acts in the design of such a furnace as a heat exchanger. Inside the casing you can find at least 6 pipes, which are adjacent to the ceiling chamber. This ensures better heat transfer in the water.

The coolant is supplied to the top point of the entire system. Then it goes directly to the radiators, and from them back to the furnace. It is there that the tap is located, through which the coolant is drained. Such a simple principle of operation of this furnace, equipped with a water circuit, provides, in use, a rapid heating of a room of any size without drying out the oxygen.

Features of equipment with a water circuit

A number of undeniable advantages are characteristic of any furnace. Buleryan is no exception. Usage efficiency this equipment largely depends on:

- in which room it will be installed;

- what expenses the owner is willing to go.

It should be understood that the prices for such installations are quite high. In addition, during the operation, you also have to bear serious costs.

The main features of Buleryan with water circuit:

- in the design of the furnace there is a gas afterburner chamber, which is located on top of the combustion chamber;

- the oven is equipped with hermetically closing doors;

- the casing with which this equipment is equipped increases the convection of hot air masses;

- an ash pan is not provided in such furnaces.

Buleryan differs from other types of furnaces in that it has a special arrangement of pipes. Due to this, heat transfer increases when using this equipment. Cold air enters the lowest pipe. When it is heated to a certain temperature, it spreads throughout the room.

It should be noted that, unlike other types of equipment for space heating, working on wood, the design of the buleryan is thought out in detail. In the combustion chamber, during the operation of the furnace, not only firewood is burned, but also combustion products. Therefore, in order to create a comfortable temperature in the room, the owner can use natural fuel to a minimum.

Furnace installation

The task of installing this equipment is not too difficult. Available materials are needed for installation work, and the methods used for installation do not present great difficulties even for beginners. Before starting installation, you should choose a seat where the oven will be located. It should be noted that its installation can be carried out at any point in the structure. The only requirement that must be met is that the equipment must be located at a distance of 50 cm from the wall.

The task of installing this equipment is not too difficult. Available materials are needed for installation work, and the methods used for installation do not present great difficulties even for beginners. Before starting installation, you should choose a seat where the oven will be located. It should be noted that its installation can be carried out at any point in the structure. The only requirement that must be met is that the equipment must be located at a distance of 50 cm from the wall.

When the installation of the furnace is completed, it must be connected to the heating system. When performing installation work, experts advise using pipes with a layer of reinforcement. The use of such products eliminates their deformation when exposed to high temperatures. In addition, they are best suited for such a heating system.

When the installation of elements of the heating system is completed, a procedure such as crimping. Then the entire system is filled with water. After that, the furnace can be started, and then you should observe its operation. If no errors were made during installation, the equipment will work properly without causing problems to the owner.

But even when using such equipment in the house, one should not forget about safety. To do this, the wall near which the furnace will be installed should be treated with fireproof material. It is applied to the wall surface above the top point of the furnace by 1 m.

Buleryan efficiency in comparison with gas heating

Before buying any heating equipment, you need to make sure that it will be beneficial for the potential owner. The stores currently offer a large number of boilers, which have a great design but are quite expensive to operate. Therefore, it is necessary to find such an installation model that has an aesthetic appearance, is inexpensive, and does not require large financial costs from the owner during operation.

Positive characteristics

It is with the advantages that the popularity of this furnace is associated, so a potential buyer should first of all familiarize themselves with them.

It is with the advantages that the popularity of this furnace is associated, so a potential buyer should first of all familiarize themselves with them.

- The use of Buleryan furnaces provides fast and even heating large premises. If the installation is equipped with a water circuit, then the generated thermal energy is easily transported even to rooms located on the second and third floors.

- This model is small.

- After installation, the owner is provided with ease of use. The installation process is not very difficult. However, a chimney device is necessary, for which it is better to invite a professional stove-maker.

- If we compare this furnace with traditional ones, then during operation it consumes less fuel. One full load will be enough for 12 hours of plant operation.

Such advantages that these stoves have, many owners of private houses will certainly be pushed to purchase buleryan. However, these installations are not without drawbacks, which you need to inquire about even before going to the store.

Such advantages that these stoves have, many owners of private houses will certainly be pushed to purchase buleryan. However, these installations are not without drawbacks, which you need to inquire about even before going to the store.

When using this furnace, it is only possible to load into the combustion chamber low moisture wood. It is advisable to use those tree species that do not form resins during combustion.

During operation, the resulting generator gases in such models are not fully used. In the combustion chamber, their combustion occurs in a volume of less than 70%, so such a furnace cannot be called perfect. Performing work on the construction of the chimney, special attention must be paid to the insulation of the pipe. If this is not done, then during the operation of the equipment condensate will occur, which will reduce the efficiency of the buleryan.

In most cases, these stoves made from metal. Therefore, a suitable protection should be placed a meter from the installation. If the location of the boiler is the corner at the junction of two walls, then you need to think about protecting them. They cannot be placed close to the walls. This is a big problem for small spaces. 20 cm is the maximum allowable distance from these units to the wall.

If you want to save space and place the stove as close to the wall as possible, you will have to sheathe them with long metal sheets that exceed the height of the stove. It is advisable to install basalt insulation between the wall and the sheet. When this is done, the metal screen will perform two functions at once - to protect the system from heating and act as an additional source of heat.

There is one more thing to be aware of. It concerns the design features of the furnace. When operating the installation in pipe holes dust will fall. During the operation of the furnace, a high temperature arises, which burns out everything in its path. When using buleryan, an unpleasant odor may occur. In addition, positively charged ions appear in the air near the furnace. They well attract particles of dirt that are inside the human body. If cold viruses predominate in the room, then the risk of illness for healthy people is high. Therefore, in order to avoid this, it is necessary to regularly ventilate the room, as well as perform wet cleaning 2 times a day.

Conclusion

Various heating systems can be used to heat a room. Recently, buleryan with a water circuit has been gaining popularity. In appearance, this boiler has its own features of operation and installation. Before purchasing it as the main component of your heating system, you need to familiarize yourself with its advantages and disadvantages.

It should be understood whether it will be beneficial to use this installation in your home. After the acquisition, you need to think about high-quality installation. If you doubt that you can correctly install this furnace and correctly connect it to the water circuit, then in this case it is best to resort to the help of specialists.