Modern gas heating boilers are one of the most profitable options for a country house. Natural gas remains the cheapest type of fuel, and since almost every large settlement is now gasified, this solution is the most popular.

gas boilers heating are as follows:

Gas heating boilers — great option not only to heat the house, but also to ensure it hot water. This technique has other advantages, we will consider them in more detail.

Advantages of gas boilers

A gas boiler for the home is a convenient solution, as it allows you to ensure stable operation without human intervention and extra costs. In addition, there is no need to look for a place to store coal or fuel. Here are some additional benefits:

- Economic benefit. The use of such equipment is cheaper than electric and solid fuel models.

- Convenient use. Gas double-circuit boilers of correctly selected capacity provide all the needs of the family in hot water and heat supply.

- Environmental friendliness. Gas burns without emitting soot and soot, in addition, gas floor-mounted double-circuit boilers are undemanding to maintain.

- Continuous work. If the flame goes out for some reason, the electronics will ignite it on their own. This will prevent gas leakage.

Varieties of gas boilers for heating and hot water

Floor and wall gas boilers

Widespread use of gas wall-mounted boilers. They take up little space, they can be installed in a city apartment, and in a country house, and in a country house. Gas floor boilers will become good decision for a cottage, where you can allocate a special room for the boiler room. Powerful hardware will provide heat to a building of any size.

Note! Gas floor single-circuit boilers may have a combustion chamber open type. Care must be taken to comply with all fire prevention measures.

Single-circuit and double-circuit gas boilers - what's the difference?

Gas wall-mounted single-circuit boilers - a good choice if the equipment is to be used for heating only. The problem with hot water in this case must be solved differently. Gas single-circuit boilers can be connected to a chimney; in this case, combustion products are removed using natural draft.

Gas double-circuit boilers can be used both for space heating and for hot water supply. It's universal heating appliances for a country house or cottage.

What brand of gas boiler is better to choose for a home?

Buy a gas boiler in Moscow affordable prices you can in our company. We offer products well-known manufacturers that have proven themselves in many countries. By contacting us, you can purchase the following equipment:

- Protherm gas boilers. The Czech company has become one of the recognized market leaders. It sells a wide range of different equipment. The products are very reliable and easy to use.

- Gas boilers Baxi. These are products of the European concern BDR Thermea, which has representative offices in many countries. The brand gained popularity due to innovative approach to the production and use of the most modern technologies.

- Bosch gas boilers. The Swedish brand has become widely known for a long time. European quality can be trusted, and a wide range of models will allow you to make the right choice.

The number of models of heating boilers is measured not in tens, but in hundreds and even thousands. A variety of modifications are presented to the choice of consumers - wall-mounted, floor-mounted, with one or two combustion chambers, with simple controls, and many others. Choosing a floor-standing gas boiler to heat their home, buyers seek to get at their disposal a modern heating equipment pleasing with their technical specifications.

In this review, we will try to explain to you how to choose a good outdoor speaker.

Floor-mounted gas boilers and their varieties

Any consumer is tormented by the age-old question - which is the best of the floor-standing gas boilers on sale. The question is really interesting, since the floorstanding category includes a huge number of models. Let's try to figure out how to buy a good unit and not make a mistake in your choice. We will consider the following types boilers:

Modern gas boilers don't have to be bulky, noisy, ugly cabinets. There are many small neat models.

- With combustion chambers of open (atmospheric) and closed (turbocharged) types;

- With steel or cast iron heat exchangers;

- With one or two contours;

- Universal with forced draft burners;

- Volatile (need to be connected to the mains) and non-volatile (work without a power outlet);

- Classical convection and economical condensing;

- With boilers for the accumulation and storage of hot water.

atmospheric and turbocharged

A floor-standing gas boiler with an open combustion chamber is the most common and simplest heating equipment. It uses an atmospheric burner with a system for the natural removal of the resulting combustion products. The burner needs a supply to operate. fresh air With necessary quantity oxygen, therefore, in the room where the floor boiler is placed, an effective forced ventilation. That is, for the installation of the unit, it is desirable to allocate a separate room, but you can get by with any other non-residential room, for example, a basement or the most ordinary hallway.

Turbocharged floor gas boiler is the most modern heating equipment with closed camera combustion. Air for the burner is taken from outside the building, through a special two-layer coaxial chimney. The products of combustion of natural or liquefied gas are removed through the same chimney. Thrust here is created forcibly, using a variable speed fan. It sucks air into the combustion chamber and removes the products of combustion of gas fuel. A floor-standing turbocharged boiler has the following disadvantages:

- Increased noise level - the fan installed inside is noticeably noisy, especially at high speeds;

- The operation of the equipment requires electricity, which limits the possibility of using such boilers in buildings without electrification;

- More complex device- how more details, the more likely it is that the turbocharged floor boiler will fail.

But there is also a solid advantage - a turbocharged floor-standing gas boiler can be installed in almost any room, and not just in the boiler room.

Type of heat exchanger

Installing a floor boiler will require a lot of free space, and due to the high noise level, it is better to adapt a separate room for this.

The most reliable gas floor heating boilers for a private house are those built on the basis of cast iron heat exchangers. They differ in solid weight, but in terms of reliability they are leaders. Cast iron tolerates impressive temperature overloads well, is resistant to corrosion, accumulates and retains heat for a long time, and does not burn out in 2-3 years. Due to its advanced technical characteristics and endurance, cast iron is actively used in especially powerful outdoor gas boilers.

Floor standing boiler with steel heat exchanger perfect solution for those who want to save money. Equipment with such heat exchangers is lightweight and easy to install, but is characterized by reduced reliability. Steel can quickly leak due to corrosion, often it bursts as a result of thermal overloads. But floor boilers with similar heat exchangers are cheaper.

Copper heat exchangers, often found in wall-mounted gas boilers, are almost never used in floor modifications - only cast iron and steel. The disadvantage of cast-iron heat exchangers is their fragility when heated - they break when accidentally dropped or hit, or when cold water enters (due to temperature changes).

Units with one or two circuits

Floor-standing gas boilers for heating a private house are divided into two large categories - single-circuit (the simplest) and double-circuit (with a DHW circuit). Single-circuit units are distinguished by their simplicity and serve only for heating buildings and premises. They use only one heat exchanger, there is no extra equipment on board. For the preparation of people need hot water, auxiliary equipment should be used:

- Gas instantaneous water heaters(those same "columns");

- Electric water heaters (eg. accumulative type or economical flow-through);

- Boilers indirect heating(powered by heating).

Floor-standing heating boilers with two circuits are more versatile units. They can heat houses and prepare hot water. To do this, they have two heat exchangers - the main and auxiliary. The burner heats the circulating coolant in the main heat exchanger, ensuring the operation of the heating circuit. As soon as the hot water tap opens, the system will turn off the heating circuit and send part of the coolant to the circuit heat exchanger.

A floor-standing gas boiler with a dual heat exchanger works according to a slightly different scheme - here the burner can heat two circuits at once. But experts constantly note the moment that heat exchangers in such gas boilers do not differ in endurance and quickly burn out. Therefore, a scheme with two exchangers is more preferable.

If you want to buy a double-circuit type floor-standing boiler, pay attention to the bundle from the usual single-circuit unit and an indirect heating boiler - such a tandem is reliable and economical. In the summer, water heating is carried out using a heating element.

Boilers with a condensing heat exchanger are considered the most advanced and economical.

Advantages of double-circuit floor gas boilers:

- Versatility - no need to buy optional equipment;

- Compactness - the equipment does not take up much space in the house or apartment;

- Ease of connection - reduces the number of pipes required for this.

There are also disadvantages - it is more complex structure, high cost, the need for regular maintenance equipment.

Floor standing heating boilers

Before us is a rather interesting category of floor-standing boilers with pressurized burners. It is more correct to call them universal, and not gas, since there are burners on sale that operate on the most different types fuels are pellets, diesel fuel and much more. The basis of the boilers are impressive bodies with heat exchangers, to which you need to purchase a suitable burner. This scheme is convenient because it allows you to quickly switch from one type of fuel to another.

Here typical example- you bought Vacation home in a village that does not yet have a gas pipeline, but one is about to appear. You buy a floor-standing boiler with a solid fuel or liquid forced draft burner and use it until the house is connected to the mains. As soon as this bright and joyful day comes, you can purchase a gas forced draft burner and install it in your floor boiler.

Please note that almost all forced draft burners are powered by electrical network. Therefore, they cannot be used in buildings without electrification.

Volatile and non-volatile boilers

Floor gas heating boilers are divided into volatile and non-volatile. The former require a mandatory connection to the electrical network - electronic control modules are used here, fans are installed for forced removal flue gases and suction clean air. Also, electricity is needed for the operation of some internal components - this is circulation pumps and three way valves.

Volatile floor gas boilers operate on electricity. Consumers and experts note that for normal operation This equipment needs a stable power supply, without surges. In order to ensure stability, the boilers are connected through stabilizers and uninterruptible power supplies equipped with batteries.

Some trading companies sell special equipment for uninterrupted power supply of gas boilers from solar energy- at night, the equipment runs on batteries.

If there are frequent power outages in your place of residence, a non-volatile boiler is the best solution.

Non-volatile floor gas boilers are distinguished by a simplified design. There are no electronics and fans, there are no electrical components. The ignition of the flame is carried out from a burning igniter or a couple of batteries. They break less and continue their work during a power outage. Therefore, they are chosen by many consumers who do not want the operation of the heating system to depend on some factors.

Convection and condensation

The principle of operation of the vast majority of gas floor boilers is the combustion of gas and the transfer of the resulting heat to the heating system (and at the same time to the DHW circuit). Here are placed simple burners, the combustion products of which are sent through the chimney to the atmosphere. The efficiency of the equipment reaches 90-92%, the equipment can be called quite economical. This scheme of operation is used in both wall-mounted and floor-standing units.

The products of combustion are full of heat - you can verify this yourself by touching the chimney. And this heat can be sent to the heating system. For this, a special scheme of work is used - condensation. Floor-standing condensing gas boilers almost completely take away heat for heating, sending the resulting condensate to the drain. The efficiency rises to a figure of 95-97%, but nothing is perfect - the advertised figures up to 115% are nothing more than a marketing ploy.

Features of condensing units:

- More complex design;

- High price;

- Only closed combustion chambers;

- The need for condensate drainage.

Condensing boilers are quite economical - they can save up to 10% of gas fuel. But the payback period will be several years, since the prices for such equipment are very high.

Popular Models

In this section, we will consider the most popular and sought-after models of floor gas boilers and deal with their technical characteristics. The review will cover both imported and Russian units.

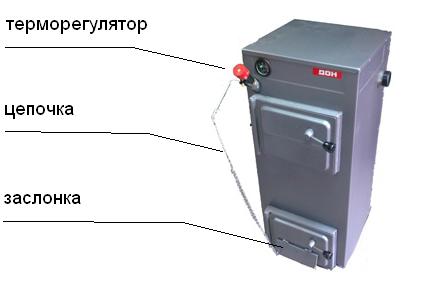

Rostov floor standing gas heating boilers RGA 8 is a very common heating equipment. The units are famous for their simplicity and good technical characteristics. The efficiency is 90%, which is high rate. The main boilers are steel heat exchangers. The equipment is designed to work in private households and premises for other purposes up to 80 sq. m. The power of the model is 8 kW.

A notable feature of this floor gas boiler is its simplicity - there is nothing superfluous inside, which indicates the increased reliability of the unit. It does not cause problems in operation and is stable. Thanks to this, many consumers choose the equipment - at a cost of only 12 thousand rubles, this is just an excellent boiler from a proven domestic manufacturer.

This brand is known to many consumers and specialists in heat engineering. The equipment produced by him is used in many houses and apartments. The presented boiler is one of the simplest in the line. The power of the unit is 12.5 kW, the heated area is up to 125 sq. m. There is an increased efficiency of more than 92%. To do this, a large two-way steel heat exchanger is provided in the design of the gas floor boiler.

The device can only operate on natural gas, it is forbidden to feed it with liquefied gas. The maximum line pressure must not exceed 13 mbar. The temperature in the heating circuit is from +30 to +80. The applied control system is mechanical, no power is required for the operation of the equipment. As protective measures overheating protection and gas leakage control are implemented.

The floor-standing gas boiler Protherm Volk 12 KSO is ideal for heating private houses. His estimated price is 15-16 thousand rubles.

This floor-standing gas boiler will appeal to those who prefer to buy heating equipment with interesting design. It is made in a vertical rectangular case, decorated with a simple pattern. The power of the model is 17 kW, heating the area - up to 170 square meters. m, the efficiency index is above 91%. Please note that the device is double-circuit, it can heat rooms and provide consumers with hot water. The unit requires an electrical connection to operate.

The floor-standing gas boiler Navien GA 17KN can operate on both natural and liquefied gas. It uses a closed combustion chamber, which allows installation in any premises. Performance DHW circuit is up to 11 l / min, the temperature in the heating circuit is from +35 to +85 degrees. The control here is electronic, with a built-in programmer. Pleased with the ability to connect the remote control. Other features:

- Built-in self-diagnosis system;

- Overheat protection;

- Work in antifreeze mode;

- Electronic flame modulation.

The cost of the boiler varies between 35-38 thousand rubles - these are quite affordable prices for equipment from a well-known manufacturer.

Before us is far from the most famous trademark, but the equipment is rated - it has earned positive ratings from buyers. The power of the model is 15 kW, the heated area is up to 150 square meters. m. The main advantage of the outdoor gas boiler MORA-TOP SA 20 is the presence of a durable cast-iron heat exchanger. It can work in heating systems with natural or forced circulation of the coolant. The second circuit is not provided on board, so the issue of organizing hot water supply should be considered separately.

The floor-standing gas boiler MORA-TOP SA 20 is endowed with an automatic ignition system, an on indicator and a simple control panel closed with a transparent decorative cover. A manometer and a thermometer are provided to control the operating modes. Maximum temperature in the heating circuit is +85 degrees. Gas consumption is 1.6 cubic meters. m/hour. The presented gas floor boiler is ideal for heating small country cottages, urban private houses and buildings for other purposes with a small area.

Video

Wall mounted gas boiler- This is one of the most economical heating options. This device allows you to regularly provide heat in the house, regardless of the availability of electricity and other fuel resources. It does not require a place to store fuel, a separate room, and also does not create additional inconvenience.

Wall-mounted gas boiler - an economical and practical option for every home

Everyone knows that the wall-mounted version of a gas boiler is one of the most popular heating options in our country. This is due to the availability and low price of gas, as well as the variety of models presented by both domestic and foreign manufacturers.

Mounted boiler has a number of advantages:

- Since release wall models launched relatively recently, all variations are modern appliances manufactured in accordance with all norms and requirements. They contain the latest developments that allow you to save, as well as provide the most high level security.

- Many models have additional equipment, the ability to heat water, connect sensors, a thermostat and more. All this makes the operation process more comfortable.

- When broken or serviced, wall boiler does not need to be dismantled. This is due to the location of all key parts in front of the case, which provides direct access when removing the cover.

- Relatively low power (up to 30 kW on average) makes a gas boiler an ideal choice for a private house or cottage. This limitation allows maximum concentration of all degrees of protection, convenient control and monitoring in this device.

- Another important plus is low cost device, ease of maintenance, as well as a wide range of models presented on the domestic market.

In addition, gas mounted boilers are light in weight, easy to install, and do not require any additional conditions operation.

Gas mounted boiler: buy a suitable model without problems

To choose perfect option purchases, first of all, you need to decide on the type, type and other parameters that distinguish them.

The first step in the selection should be the type of operation of the device. It can be single-circuit, and provide heat in the house, or it can be double-circuit, also providing hot water. The second option will be an ideal choice for a private house in which there is no hot water supply.

As you know, there are two main types of double-circuit boilers:

- Bithermic - is a design consisting of two tubes located one inside the other. They have different diameters, and coolant flows through one, and water for technical needs flows through the other. Such a system intensively heats the coolant, which transfers heat to process water.

- Duothermic - have two independent systems, each of which heats DHW water, or coolant, respectively.

In addition, when choosing, it is important to take into account such a parameter as power. In this case, it ranges from small values of several kW, and reaches about 30. It is worth noting that the wall-mounted boiler is limited in power, so it will not suit large rooms. The calculation of the required power must be made taking into account such parameters as the area of \u200b\u200bthe room, the height of the ceilings, the presence of windows, and their number. In addition, the condition of the roof, as well as the presence of thermal insulation, plays an important role in choosing the power value.

Wall-mounted options for gas boilers have certain disadvantages, although it is easier to call them features, since when certain conditions they don't work at all heating system:

- Shorter service life compared to outdoor options.

- Limited power due to small size device.

- Limited range of models compatible with antifreeze fluids.

- The need to use water that meets the requirements as a heat carrier.

In conditions not big house or cottages, low power can hardly be called a disadvantage, as is the restriction on the use of antifreeze in areas where the heating system does not freeze through.

Gas mounted boiler: price and purchase

If you need a new wall-mounted boiler, buy it can be found in our online store. We have presented various models domestic and foreign production, differing in the type, type of coolant used, as well as power, which varies from the lowest - 3 kW, to the maximum - 70 kW. Therefore, you can buy boilers from us both for a large house and for a small cottage.

You can buy a mounted boiler from us, the price of which will not exceed 6000 rubles. We also offer accessories for most models. These are wireless control panels, street and room temperature, thermostats, thermostats, timers and much more.

In order to make the most accurate choice, you can contact our managers. They will help you calculate required power, advise correct option that suits your heating system. In addition, they will help you make a purchase and arrange delivery in the most convenient way for you.

In most cases country houses in the central regions of Russia they are building near the passage of gas pipelines. Therefore, the bulk of consumers choose gas boilers for heating with water as a heat carrier. Modern market offers great amount devices that differ in many ways.

Gas heating boilers for the home

Devices running on natural or liquefied gas do not have any special differences. They are divided according to other criteria:

- At the place of installation - wall, floor and parapet devices.

- By the number of circuits - one or two.

- According to the method of ignition of the burner - a piezoelectric element or electric ignition.

- By type of traction - natural or forced.

- By power - single-stage or two-stage.

- According to the type of burner - atmospheric or inflatable.

- By type of combustion chamber - open or closed.

- According to the material of the heat exchanger - steel or cast iron.

These are the main parameters by which one can classify gas units. But modern manufacturers They also produce a lot of models and brands that differ in the presence or absence of additional functions.

Solid propellant double-circuit boilers

gas boilers floor type- traditional units with big power. They are used to heat any premises, the area of \u200b\u200bwhich goes far beyond the scope of an ordinary residential building - industrial and public buildings and structures. In addition to heating, floor boilers, if necessary, can heat water for domestic needs and for a warm water floor. To do this, one or more circuits are installed in the boiler. Therefore, the weight of floor devices can reach up to 100 kg.

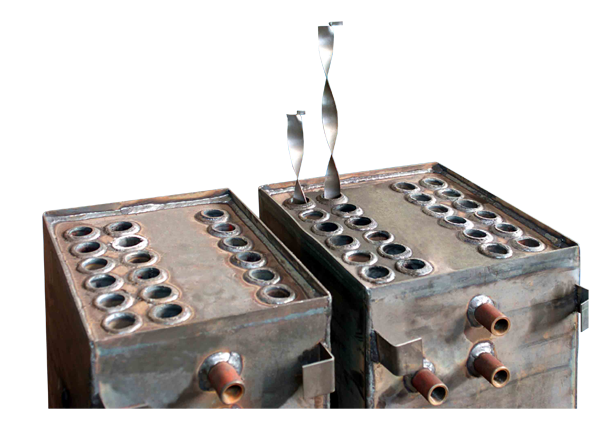

Heat exchanger in floor standing boilers can be made of cast iron or steel.

Note! When using a floor-standing gas device in a house, it is necessary to allocate a separate room for its installation - a boiler room, which should be equipped with a chimney and a ventilation system.

At the same time, the height of the chimney pipe must be at least half a meter higher than the roof ridge, which is required for better traction. In addition, the room in which the gas boiler is installed must have front door at least 80 cm wide, facing directly onto the street.

There are certain rules for installing gas devices of this type. And the gas boiler itself should be installed and connected to the main gas pipeline only by specialists who have the necessary permits- a license to carry out such work.

Wall mounted gas boilers

Wall units appeared relatively recently and immediately gained wide popularity among the population. This is facilitated by their attractive appearance and compact size, allowing you to place the unit in the kitchen or in other small spaces.

Despite their small size, these devices have all the functionality that floor structures, but have less power. The small and beautifully designed body hides the burner and expansion tank, pump for forced circulation coolant, pressure gauge and other automatic devices that allow you to maximum efficiency use wall gas equipment.

Like floor device, wall-mounted boiler can not only heat the room, but also produce hot water. The control of such units is fully automated, which allows you to set certain parameters for the operation of the entire heating system. Can be installed temperature regime for different times of the day, and when the gas supply is interrupted, the device turns off independently and turns on automatically when the gas supply is resumed.

Parapet gas boiler Kolvi

These devices are called smokeless boilers, and they are the middle link between wall-mounted and floor units. They do not require a chimney, since the products of combustion are removed using coaxial chimney, arranged directly in the outer wall.

Parapet boilers can be located anywhere in the room - even under the window. They are mainly used for heating. small houses and apartments in high-rise buildings where there is no possibility to arrange vertical chimney channel. Their power varies between 7-15 kW, but, despite such a small indicator, they, along with space heating, successfully produce hot water for domestic needs.

Note! The advantages of such devices include the fact that when the gas burner is operating, oxygen is not taken from the living quarters, which only benefits the residents.

The heat exchanger of the parapet boiler is made of 3 mm steel.

The uniqueness of these designs also lies in the fact that heating and hot water supply can be connected to the gas main and pipelines from any side. This design of the parapet boiler heat exchanger allows it to be installed in kitchens of a small area, where it organically fits into the space.

What does one or two circuit boiler mean?

Wall-mounted double-circuit boilers

When choosing a gas heating boiler, the homeowner must first decide why he needs such a device - to heat the house in winter time or even have hot water.

For a water heating system, a device with one circuit is quite suitable. You can, of course, connect a separate boiler, which will heat water for domestic needs. But this will take up extra space and increase the cost of installing equipment.

Domestic gas heating boilers with two circuits will better cope with the task of heating a house and simultaneously heating water. In addition, such devices will take much less space indoors, and ultimately the cost of equipment will be lower, given that there is no need to purchase a boiler and install it.

A device with two circuits can operate in instantaneous water heating mode or have a built-in boiler inside. Flow heating useful when the need for hot water is small. Boilers with a built-in boiler are preferable for big family when water consumption increases according to the number of people living in the house.

Type of traction - what is it?

All devices operating on natural or liquefied gas can be natural draft or forced.

Natural draft units

Gas wall-mounted double-circuit boilers

Natural draft implies the consumption of air necessary for combustion of gas directly from the room where the gas boiler is installed.

When gas is burned, water is formed in the form of steam and other chemical substances, which are discharged outside the premises using a vertical chimney. Surely, many could observe wisps of smoke over the roofs of houses in winter, although furnace heating in such houses has long ceased to exist, except for trendy fireplaces. This is not smoke, but hot steam released during the combustion of gas.

Devices with this method of removing fuel combustion products are also called atmospheric boilers. Their cost is low compared to other analogues, and they are simpler in design.

Advantages of atmospheric devices:

- energy independence

- low cost

- noiseless operation

The disadvantages include the fact that during periods of pressure drop in gas pipelines, the operation of the devices leaves much to be desired. There is a risk of burning gas burners, since the flame at low pressure can go inside the burner or even die out. Unstable pressure in the lines leads to excessive fuel consumption, which undoubtedly affects the wallets of consumers.

Forced draft devices

They are also called fan or pressurized boilers. They are equipped with a closed combustion chamber, and the products resulting from the combustion of gas are removed using built-in fans.

These devices have so far a short history, since they appeared on the market not so long ago. However, their benefits have already been appreciated by many consumers around the world. The fact is that the removal of combustion products is carried out not through a traditional vertical chimney, but through a special outlet called coaxial. In addition, oxygen, which is so necessary for gas combustion, is not taken from the room. It enters from the outside of the house thanks to the operation of a fan built into the coaxial chimney.

The design of the coaxial chimney, called "pipe in pipe", consists of two pipes different diameter inserted one into the other.

Important! Combustion products are discharged through a pipe of smaller diameter, and fresh air is supplied from outside through the space between the large and small pipes.

The advantages of such devices:

- They do not burn oxygen in the house, so there is no constant draft.

- No vertical chimney required.

- Stable operation even with a decrease in pressure in the main gas pipelines.

- Reducing installation and operating costs.

- Possibility of installation in any room.

The disadvantages of such equipment include noise from the operation of the fans, relatively high cost and dependence on the power supply.

Which heat exchanger is better - steel or cast iron?

The heat exchanger is the main element in the design of the heating device. And here, when deciding which is better, opinions are divided.

Cast iron structures

Cast iron heat exchanger

Cast iron is more durable than its steel counterpart. But it is much heavier and is used mainly in floor-type boilers. At the same time, a cast iron heat exchanger is less prone to corrosion due to the wall thickness.

According to the duration of operation of a cast-iron and steel boiler, the terms are as follows:

- cast iron - 30-40 years

- steel - 15-25 years

Cast iron heat exchanger is more resistant to chemical active substances. And this means that it can be used in systems where the coolant is antifreeze or other similar liquids.

Possessing greater inertia due to its mass, cast iron retains the accumulated heat longer, since the design of the heat exchanger of this material is made in the form of several sections.

The disadvantages of a cast iron heat exchanger include:

- Excessive brittleness of the material, which requires care during its transportation and installation - microcracks can form in its structure upon impact.

- Demanding on the composition of the coolant, since hard water poses a risk of rapid failure.

- The cast iron heat exchanger is sensitive to the difference in water temperature at the inlet and outlet. So submit too cold water it is highly discouraged, and in order to avoid such a situation, a coolant temperature control unit is arranged at the inlet.

- There is a risk of destruction of cast iron during constant overheating, therefore, constant monitoring of the temperature of the coolant is required.

Important! Although boilers with a cast iron heat exchanger are more often used where wood is used as a heat source, they are easily converted to natural or liquefied gas by replacing the burner.

Steel heat exchangers

Tubular heat exchanger

Steel structures are lighter in weight and have a more attractive appearance, so they fit better into the interior of the room.

Steel, unlike cast iron, is a more ductile material that is not afraid of mechanical impact. Its advantages lie in the following characteristics:

- resistance to temperature fluctuations

- transportation and installation are not difficult

The disadvantage of steel heat exchangers is the possibility of corrosion. However, this shortcoming is eliminated correct installation and operation. The main thing is to prevent the coolant temperature from dropping below the “dew point”, which should be taken care of automatic system boiler control.

Copper devices

Appeared on the market gas appliances where the heat exchanger is made of copper. Naturally, the cost of such units is much higher than all known ones. However, it is offset by the mass of advantages of such a device:

- Due to the properties of copper, the walls are heated evenly without local overheating of the coolant.

- The minimum amount of sediment and scale inside the copper heat exchanger.

- Thanks to the small specific gravity copper and the heat exchanger, and the boiler itself have a low mass.

- Copper is resistant to corrosion.

- The coolant in such devices moves at a higher speed, which does not allow scale to form on the walls.

- High efficiency.

- It turns out that such heat exchangers, not counting high price, have practically no drawbacks.

Ignition type

Electric ignition of the boiler

You can start a household boiler in one of two ways:

- using manual method- matches or lighter

- by built-in modern devices - piezo ignition or electric ignition

Electric ignition allows you to save blue fuel, since with this method there is no constantly burning wick (igniter). And for a year, such a device can burn up to 100 cubic meters of gas. If the power supply suddenly stops, the boiler stops working and turns on automatically as soon as the power supply appears.

Piezo ignition requires manual activation of the boiler, but its advantage lies in the independence of the availability of electricity.

Types of gas burners

V heating devices two types of burners are used:

- atmospheric

- supercharged, or fan, modulating, mounted or replaceable

Note! Atmospheric burners are usually included in the composition and cost of the boiler, while mounted ones are purchased separately.

The first type of burners has the simplest device and operates almost silently.

Pressurized allow you to create a more economical mode of operation of the boiler and maintain the desired temperature of hot water both in the coolant and in the hot water supply system. Such devices are characterized by high efficiency, although their cost is much higher than atmospheric ones.

If atmospheric burners install in heating units with a power of up to 80 kW, then supercharged ones can be used in devices with a power reaching several thousand kW. This circumstance enables the consumer to choose a household gas boiler with optimal power.

Power of heating devices

Wall-mounted double-circuit gas boilers

Houses in terms of power can be single-stage or two-stage.

Single-stage devices operate at one constant power level, which is inefficient in terms of gas consumption. After all, the house is heated only 5 months a year, and at the same time, the full power of the operating equipment is not always needed.

Two-stage devices allow:

- regulate the flow of gas, which leads to savings

- reduce the number of switching on and off the boiler, which leads to its long operation

- limit the amount of harmful emissions into the air around us

In addition to two power levels, gas equipment is equipped with a smooth switching of the consumed gas, which is called modulation. This function allows you to better save fuel consumption and share the boiler and boiler different capacity installed separately.

It is important to know that gas appliances with a power of more than 30 kW should be located in separate rooms with individual exit to the street, chimney and ventilation.

Conclusion

All household gas boilers are designed for space heating, regardless of their purpose - be it city apartment, country cottage or small private house in the village. Modern devices can still produce hot water for domestic needs of the homeowner and his family. Therefore, when choosing a particular device, you need to pay attention to its functionality. Among them, an important place is occupied by the material of the heat exchanger and the power of the equipment, the dependence on the power supply and the type of chimney.