I already did a review about this soldering iron. But time goes by, and the manufacturer makes changes to its products. There are good changes, and there are not so good ones. I (and not only) liked that soldering iron. So we decided to order the same ones for work, two at once.

At that time, the store had a small discount, so they cost me US$25.98

for a couple. The parcel came in three weeks with a full track. Strange, but nothing was crumpled.

I liked that soldering iron. Everyone liked him. So we ordered two.

The brand and model of the Tomizawa HM-880 soldering iron are indicated.

The box has a link to the manufacturer's website:

But he is not available. Everything is shrouded in mystery.

WITH reverse side there is information on stings.

But I recommend using Hack's notation. It's more familiar.

Soldering irons came with a non-European plug. There are no options on the store page.

This is probably why two adapters / adapters came as a gift in the kit.

I recommend using one of these:

When you know what each type of heater has to offer and what each does best, you can decide which one is right for your situation. The first step is to decide which area you need to heat. For example, if you need to heat large area, ceramic heater probably not the best the best choice. If you are looking for an inexpensive heater that is environmentally friendly, then this would be a good option.

Then determine what your specific needs are. Things like cost efficiency, temperature control and comfort are all things to consider when choosing a heater. While all of these heaters will help you stay warm, how they provide heat and the type of heat they provide can affect how effective they are at home. different situations.

At least there will be some protection.

I turn to the external examination.

I noticed an incomprehensible knob on the cord (surprise No. 1). Dropped the nut. And there is nothing interesting. Regular socket.

There are soft rubber bands in the place of grip and cable entry. Exactly like a soldering station.

The cable is stiff, about a meter long.

When turned on, the soldering iron “blinks” the LEDs and goes into standby mode. In standby mode, the display turns off. When you press the button sequentially (in a circle) switches temperature conditions up to standby mode. Switching is accompanied by light indication.

Assess your needs and personal opinions about each type of heater, think about what you want from a heater, and then choose the one that best suits you. Once you install a safe heater and start using it to heat your home or office, you'll be glad you invested in a good heater this winter.

Tensile strength at high temperature

These high performance elements have outstanding thermal properties in a ceramic heater, including high thermal conductivity and anisotropy. The required minimum information is as follows. Heater heating data Ø4. Thermal gradients heater Ø10.

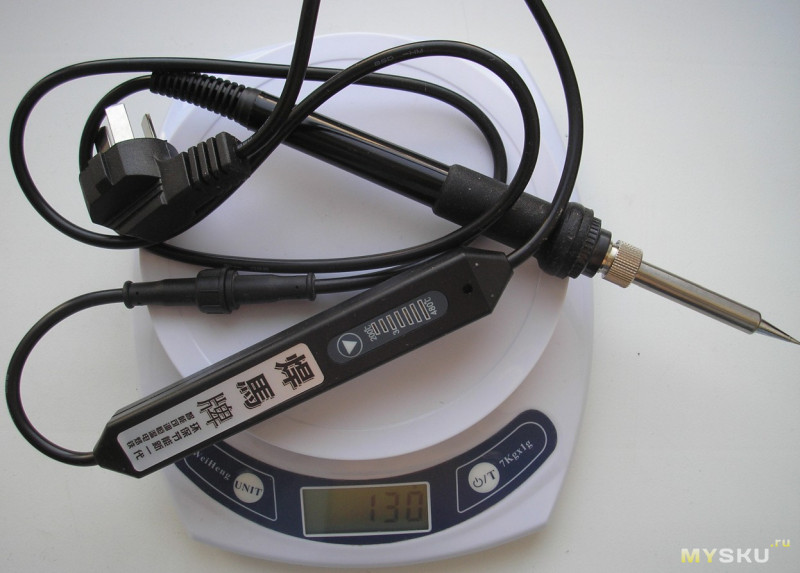

I weighed it just in case.

The previous version was a little lighter.

I turn to the study of the soldering iron itself.

First, I compared the sting from the new batch with what was sent last time.

Compatibility with Hakkov stings is absolute. The new sting is much better. And there is more copper, and the dimensions are better. Everything fits perfectly with a small gap for expansion when heated.

But to compare, at first the soldering iron was dismantled. There are no difficulties.

Checked with a magnet.

Only the nose part is magnetic.

After an hour of work, the temper went.

Made a drink to see what it's made of.

Steel glass inside, outside thick layer copper. External coverage is minimal.

I measured the depth of the inner cavity of the sting and the length of the protruding part of the heating element. The match is perfect.

This is a soldering iron with a ceramic heating element. Nichrome heaters look a little different, they have cement on top of the joint. Ceramic ones usually have such a step (although they have learned how to fake steps) and a groove (they don’t fake it yet), as in the photo. ![]()

Brief information on ceramic heaters. Taken from the internet.

Mainly used for heating water, liquids and oil products. They are primarily installed in tanks and containers where the heating element is placed inside a pipe so that the heating element can be changed without lowering the tank or container. When using pouring tubes, a large surface area is achieved for better heat distribution, which allows you to install more power in a container with a ceramic heating element.

Curved - FTE; NTE; QTE; QCE; LFTE

Round ceramic heating elements are made of blocks of grooves. Regardless of the diameter, they are available in min. Length 50 mm. The groove blocks are combined to complete the heating elements with the heat transfer medium placed in the grooves. On the largest diameters, they can be combined with lengths up to 10 meters.

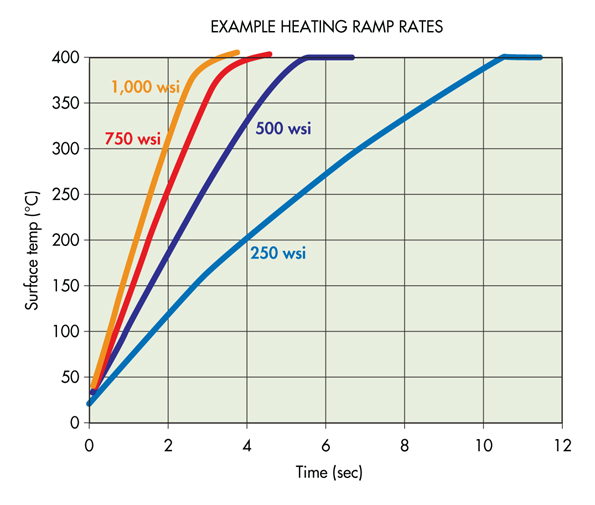

The tubular ceramic heater is produced by printing with finely dispersed tungsten powder on a ceramic substrate, which is wrapped around an aluminum oxide ceramic rod and sintered in a hydrogen furnace flame at t=1500 °C, forming a strong, durable, heat-resistant element with a high insulation resistance of more than 100 MΩ, and can reach temperatures up to 700 °C.1. It was this property that I observed when the power of the soldering iron dropped with an increase in temperature on the remote control.

The electrical resistance of this heater increases with increasing temperature (PTC - Positive Temperature Coefficient).

2. A characteristic technological groove on the heater is also present.

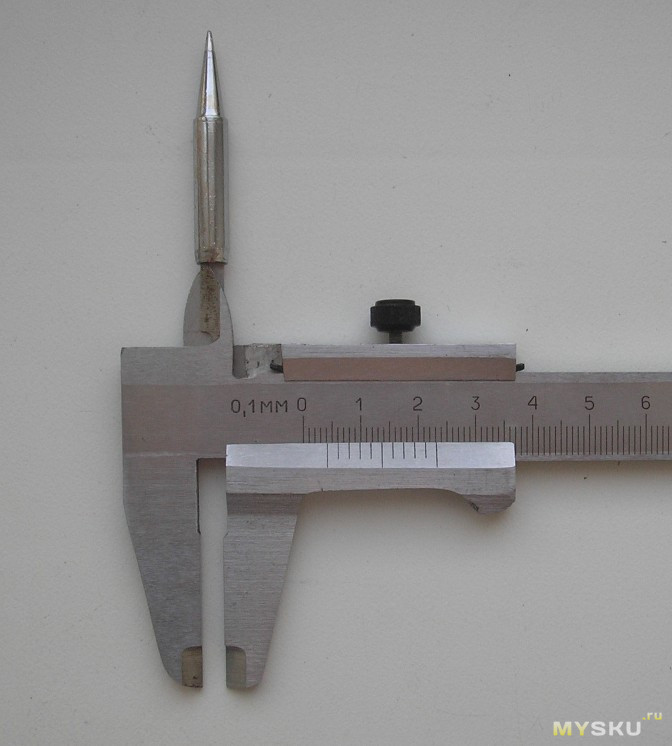

The outer diameter of the heating element is 3.8mm.

The inner diameter of the tip showed the same 3.8mm. In fact, it's a little more. This is a feature of the "stall" when measuring internal small holes.

The heating element enters freely. There is a minimum backlash (for expansion when heated).

Outer diameter 6.2mm.

I understand further.

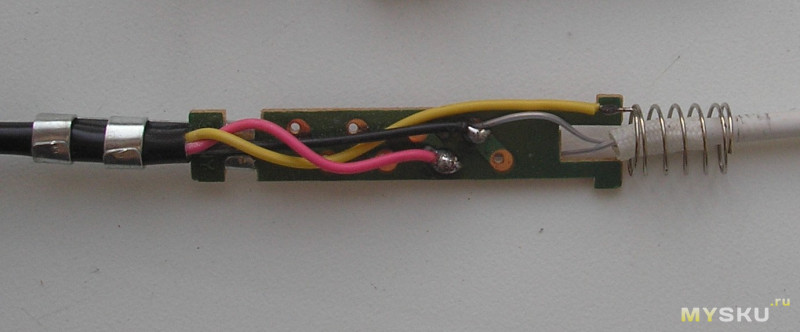

Three wire wire. Clamped well.

The thermal stabilization mode is implemented in an unusual way. There are only two wires going to the heating element. There is no thermocouple. Most likely, the temperature measurement is implemented by monitoring the change in the resistance of the ceramic heater or current.

The third wire goes to the body to the spring.

I turn to the temperature control unit.

It is on a cord. There is a hole for adjusting the temperature.

Attached with four screws.

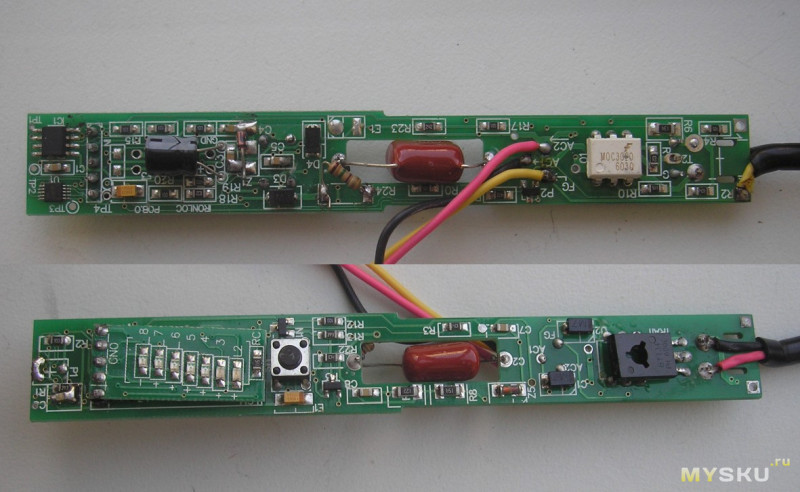

You can see more closely (view from both sides).

The flux is not washed. You can consider the main elements in more detail:

MOC3020 optocoupler, microcontroller, LM358 op amp, temperature indicator and BT134(-600E) triac. ![]()

I'm moving on to testing.

Worked with a soldering iron for an hour.

The sting got off well. Soldering is a pleasure. But the "lace" could have been longer.

After an hour of operation and acceleration to a temperature of 480 ° C, traces of tint appeared on the sting.

Measured power. When you turn on a cold soldering iron, the power is maximum. Then it falls off a little.

Heats up quickly. But it heats up in small portions, turning on and off the heating element. Therefore, it is difficult to track the real power, although some patterns are noticeable.

With warming up, power consumption decreases. Probable Cause- increase in the resistance of the heating element.

I will repeat once again. Heats up in small portions, then turning on, then turning off the heating element. Therefore, the real (average) power consumption is much lower.

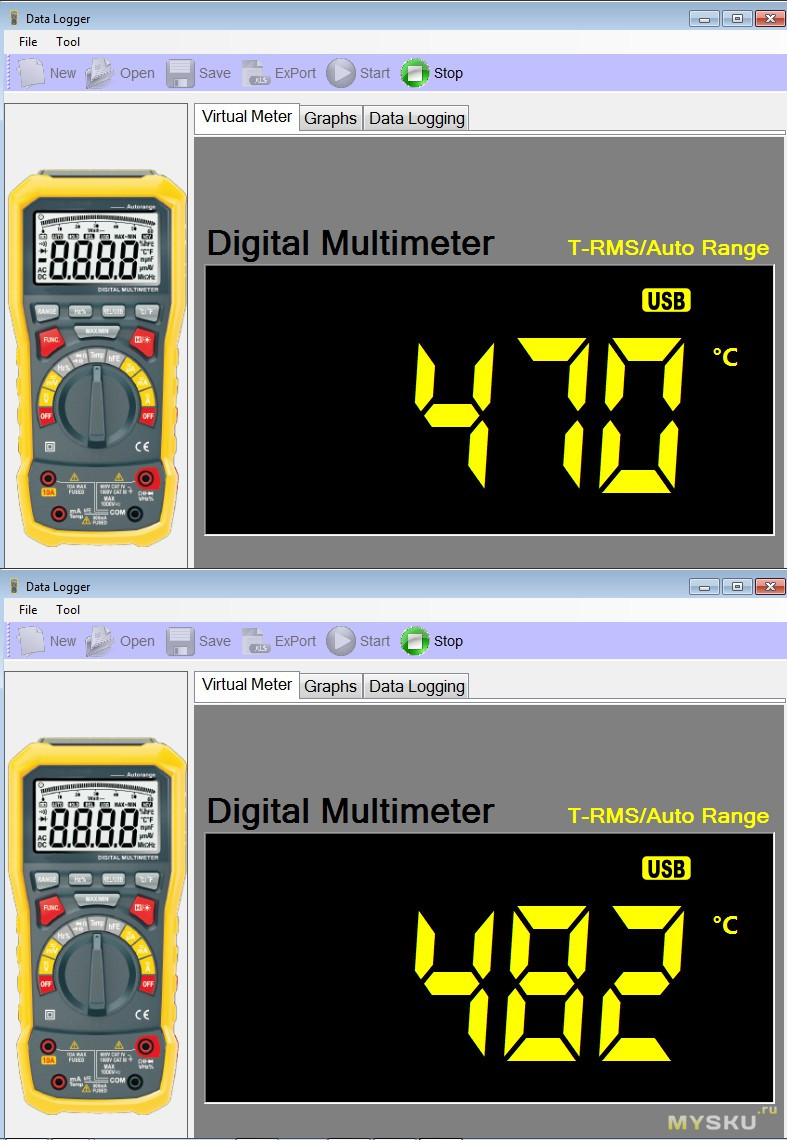

It remains to check how accurately it maintains the temperature. I will use a device with access to a computer. It's easier.

In order not to spoil the thermocouple, I measured the temperature not at the very tip, where there is no solder.

Sequentially pressed the button on the remote control:

200˚С→250˚С→300˚С→350˚С→400˚С→450˚С→480˚С.

Used to heat the bottoms and sides of bathtubs, etc. they are also well suited for building small annealing and hardening furnaces, or for installation in cartridges with hanging screws or clamps. Flat ceramic heating elements are made of heat-resistant conductors and ceramic parts that support the resistive conductor.

Flat ceramic heating elements are made of grooves. We design voltage, power and cold zone on request for every application. call Additional information and order. The smoke and flames may seem prehistoric. But all four of these inventions - and dozens more - besides - rely on fire in one or the same way.

These are not final statements. The temperature varies. I will repeat once again. Heats up in small portions, then turning on, then turning off the heating element (as it heats up). During soldering, the temperature may drop by 20˚-30˚С.

At the usual operating temperatures, the soldering iron clearly overestimated. I remembered the trimmer. But I did not find it in this soldering iron (surprise No. 2). Here is a photo of what is and what was.

This variation in temperature did not suit me at all. First, he “broke the snot” at the place of variable resistance. Then, a resistance of 7.5 kOhm was soldered to the place of the break.

The resistance was selected according to the temperature of the tip and the temperature of the remote control.

With an additional resistance of 5.1 kOhm, the tip temperature (at a temperature on the remote control of 200˚С) = 240˚С.

With an additional resistance of 9.1 kOhm, the tip temperature (at a temperature on the remote control of 200˚С) = 180˚С.

With an additional resistance of 7.5 kOhm, the tip temperature ideally (or almost ideally) coincides with the temperature on the remote control over the entire range.

Now everything suits me.

It's time to sum up.

Pros:

+ Ceramic heating element.

+ Compatible with Hakko stings.

+ Temperature control.

+ Thermal stabilization.

Minuses:

-Short power cord.

- NOT our mains plug.

- I had to work a little with setting the resistance.

Here, in general, that's all. For correct conclusion what you wrote should suffice. If something is not clear, ask questions. Perhaps I missed some points.

Hope it helped at least someone.

Good luck!

Fire is nothing but shiny, but it's not that convenient. Sometimes it takes a long time to get a fire going: coal-fired engines need to be started hours before they need to pull trains, for example. Fire breaks out when you least expect it, threatening lives, buildings, and everything you hold dear. It would be great if fire was as easy to control as electricity, so you could turn it on and off right away. This is the basic idea of heating elements.

They are the "fire" inside things like electric heaters, showers, toasters, stoves, hair dryers, clothes dryers, soldering irons and all sorts of other handy household appliances. heating elements give us the power of fire with the convenience of electricity Let's take a closer look at what they are and how they work!

Used as a stand-alone or auxiliary equipment. They are characterized by miniaturization and high performance, quickly heating the air in the premises. Best Choice a ceramic fan heater will become the type of heating element. It will create a comfortable atmosphere in the rooms without drying up the air and without burning oxygen.

Photo: typical electric fire standing on stone hearth. It has three electric heating elements set in white ceramic behind a silver safety net. You can see the elements right in the middle of the image going horizontal and glowing red. At the top there is a rather unconvincing pile of plastic charcoal that does not serve any purpose. useful purpose except to remind us that we are at heart. We still love the romance of fire, even if we prefer the convenience of electricity!

We can achieve the same conclusion with mathematics. The power generated or consumed by the flow of electricity is equal to the voltage times the current. In other words, heat is proportional to resistance, but also proportional to the square of current. Thus, current has a much greater effect on heating than resistance. Double the resistance and you double the power, but double the current and you quadruple the power.

In this review dedicated to ceramic fan heaters, we will look at:

- design features of ceramic models;

- types of ceramic heaters;

- equipment functionality;

- security systems for ceramic fan heaters;

- their merits and demerits.

After reading this material you will receive maximum information about heaters with ceramic heating elements.

So what really matters is relevant.

However, there are also advanced ceramic heaters that have different type heating element. The heating element is often described as the "resistor trace" of the deposited material. This material is usually flat rather than coiled wire in traditional heaters. The trace can be applied through various processes with thick film, such as screen printing.

It is useful to reconsider the properties ceramic materials to better understand how the performance of advanced ceramic heaters occurs. Ceramic materials are inorganic solids and may have a crystalline or partially crystalline structure, or may be amorphous. Pottery is one of the earliest examples of human use of ceramics. Pottery is made from naturally occurring clays that harden when baked at high temperatures.

The device and principle of operation of a ceramic fan heater

Due to their design, tangential fans are used in wall-mounted and elongated floor models.

The main components of any such device are the fans themselves and the heating elements. Fans that drive air can be tangential or axial. The former are used in stationary models, most often in wall-mounted ones. They differ large sizes, allowing you to distill large volumes of air masses. At the same time they have a minimum noise level.

Over time, engineers developed new ceramics for specific applications. These materials are produced synthetically with exceptional purity, so they can provide special mechanical, thermal and electrical characteristics. Are common production processes for these materials include the pressing of powdered raw materials at extremely high pressures followed by sintering at high temperatures. Controlled purity and chemical composition of the obtained material gives monolithic, geometrically stable structures, which are of interest for use as a heater.

Axial fans rotate at a higher frequency than their tangential counterparts. It is due to this that their high performance is achieved. But noise level generated axial fans easily overshadows other benefits. However, if the manufacturer used quiet fans and motors, then the noise level will be quite acceptable and is unlikely to prevent you from falling asleep.

Materials that can be used in modern ceramic heaters include alumina, silicon nitride, beryllium oxide, and aluminum nitride.

Each of the advanced ceramic materials has its own mechanical, thermal and electrical properties. Designers use these properties to match certain ceramics with specific heating applications.

Heating elements for heating planes

Aluminum nitride is particularly interesting because it has a high thermal conductivity as well as a good electrical insulator. High growth rates of this kind can save time in applications such as clinical diagnostic equipment and semiconductor chip testing where cycle time is critical.

Tangential fans are used in wall and ceiling heaters, as well as in the indoor units of standard household split systems.

Ceramic plates contribute to the rapid heating of the air, despite the fact that they themselves do not heat up to high temperatures.

It undergoes high temperature sintering which creates a heater that is hard and dense with virtually no porosity. This property, combined with its ultra-high dielectric constant, makes it attractive for applications requiring low leakage current. Low leakage current can be critical for medical applications that are in close proximity to patients.

Equipment that incorporates traditional heating technologies may need to rely on isolation step-down transformers and low voltage power supplies to meet company safety requirements. They are usually a few tenths of an inch. Round ceramic heating elements are mainly used for indirect heating water, liquids, oil products, furnaces and machines. In particular, ceramic heating elements are built into vessels and containers, where the heating element is placed in a tube welded or screwed into the vessel.

Back to the heating elements – ceramic fan heaters, as you might have guessed, use ceramic heating elements. Unlike their spiral counterparts, they practically do not dry the air and do not burn oxygen, since there is no direct contact between hot metal and air masses. Heating is carried out exclusively due to ceramic plates. This scheme allows:

This installation method is an advantage when using direct heating, as the heating element can be replaced without emptying the vessel. Ceramic heating elements are also ideal solution for heating oil and bitumen, since the medium can burn on the surface of the heating elements due to the high temperatures generated by direct heating.

Ceramic blocks are assembled to complete the heating elements with a heating conductor placed in ceramic grooves and when using large diameters ceramic elements can have a length of up to 10-11 meters. If the element is to be installed in a vertical position, the heating conductor will be secured to prevent it from "sagging" during use.

- save chemical composition indoor air;

- slow down heat load on equipment cases;

- get rid of the combustion of dust - this helps to get rid of an unpleasant odor;

- increase fire safety equipment - ceramic fan heaters are as safe as possible for almost all types of premises.

Fan heaters with ceramic heating elements heat up less and warm the air better, do not burn dust and do not fill heated rooms with burning aromas. At the same time, heating is carried out much faster than when using spiral heating elements.

The main areas of use of ceramic emitters

If the heating element is built into the welded pipe and installed horizontally, weld must be directed upwards so that the distance from creep does not decrease. The indicated power is intended only as a guide in connection with the choice of physical measures. When preparing the final dimensions, it is important to compensate for the position of the heating element, the operation and the ambient temperature.

Flat inserts, cylindrical and semi-cylindrical shapes are available and can be customized to suit your requirements. For custom heater design and development, please contact us directly. Available types of heating elements.

The principle of operation of ceramic electric fan heaters is extremely simple - the fan sucks air into the device, where it is heated from a ceramic heating element heated to high temperature. After that, he goes to the premises, gradually warming them up throughout the volume. Thanks to the use of efficient fans, these heaters are able to create a warm atmosphere in a matter of minutes.

The practical use of such devices shows that a room of 20 sq. m warms up literally in 15-20 minutes - it becomes noticeably warmer in it. For the simplest convectors, the warm-up time is 2-3 hours.

Device device: 1 - case; 2 - ceramic heating element; 3 - fan; 4 - control unit.

Ceramic fan heaters for the home have simple device- they are based on only three elements:

- the fan itself - it ensures the passage of air through the heating element;

- heating element with ceramic plates it almost instantly heats the air to a certain temperature;

- control circuit - ensures the maintenance of the set temperature.

Also in the design of ceramic heaters there are timers, step power controllers, ionization systems, air filters, automatic rotary mechanisms, air humidifiers and much more. All this allows to provide convenience of management and the comfortable and healthy atmosphere in heated rooms.

Advantages and disadvantages

The main advantage of any fan heater is a very fast heating of the premises.. While ordinary heating appliances they try to smoothly warm the air and surrounding objects, fan heaters drive large flows of air masses through themselves, ensuring the creation of heat. The performance of these heating appliances is from 50 cubic meters of air per hour - the most powerful models can drive through themselves and large volumes.

Due to their design and ceramic heaters, these devices heat up the room very quickly.

Other advantages of ceramic fan heaters:

- fire safety - there are no open heating elements in direct contact with air. Therefore, they rarely cause fires. Another factor affecting the safety of property and real estate of citizens is the absence of overheating of buildings;

- miniature - the simplest household appliance with a power of 1-2 kW is a small design that can easily fit in a shoe box. Thanks to this, consumers have the opportunity not to spoil the interiors with bulky heating equipment;

- an abundance of varieties - allows you to solve any problems of space heating. For example, there are for sale powerful devices, which can work as a thermal curtain. They are installed in doorways, preventing the penetration of cold air from outside the premises;

- ease of management - the most simple models controlled by just one handle, combining a switch and a thermostat;

- mobility is another important argument in favor of fan heaters (and almost any). They can be quickly moved from place to place, providing the creation comfortable conditions where it's needed.

Not without drawbacks:

It is impossible to get rid of the noise during the operation of the fan heater, it is very disturbing during sleep.

- not everyone likes excessively hot air - its accumulations are observed directly near the equipment. Therefore, the fan heaters should not be pointed directly at people;

- noise - no matter how quiet the fans used, it is impossible to completely get rid of noise. This makes some people uncomfortable at night;

- it is not recommended to use fan heaters as the main heating equipment - they best cope with the role of auxiliary equipment (for example, they will help come in handy in the country or in the apartment when the central heating suddenly turned off).

The disadvantages are not the worst, but the presence of any noise is a clear minus.

Wall-mounted ceramic fan heaters used as thermal curtains make the loudest noise. But they are not designed for residential use.

Types of ceramic fan heaters

Ceramic fan heaters are available in several form factors. They are:

- desktop;

- floor;

- wall;

- ceiling.

Table fan heaters

Desktop fan heaters are clearly a marketing ploy, since in their appearance and all other parameters they resemble the most common floor models, which they are. They differ small size and compactness, as well as very easy operation. Such models are equipped with simple mechanical thermostats and power switches. Some of them are equipped rotary mechanisms allowing for more uniform distribution heat in heated rooms.

Imagine desktop operation such a device is very difficult - after all, hot air flying at a person will irritate, and not cause a feeling of comfort. However, if there is a function of operation in the cold fan mode, then everything is not so bad.

![]()

Floor ceramic fan heaters

Floor ceramic fan heaters are close relatives of desktop models. In fact, this is what they are, only some models may differ in increased sizes. For example, there are vertical models on sale. They have good modern appearance and attractiveness, allowing you to heat a large area with minimal own sizes. The height of their bodies is 50-100 cm.

Wall-mounted ceramic fan heaters

Wall-mounted ceramic fan heaters are somewhat reminiscent of thermal curtains and indoor units split systems at the same time. There are tangential fans that provide a continuous run of air masses. Air heating is carried out using the same ceramic heating elements, located horizontally. With a view to more convenient operation such devices are endowed with remote controls remote control - no need to reach for the buttons when the fan hangs at about the same height as the split system.

Ceiling fan heaters

Ceiling fan heaters - this is not very common heating equipment designed for installation in rooms with high ceilings. In everyday life, floor or wall models. But ceiling models provide a more uniform distribution of heat - this is their definite advantage.

Considering the types of fan heaters, it is impossible not to note their division by functionality. They meet:

- additional air filters - they trap dust particles scattered by air currents, which only improves the atmosphere. Allergy sufferers will be happy with such an addition;

- air ionizers - saturate the air with useful ions that support human health;

- air humidifiers - despite the absence of a heated coil, ceramic fan heaters can slightly dry the air in the rooms. The presence of a humidifier will improve the health of people and normalize sleep;

- functions of work as a conventional fan - the equipment drives through the air without heating;

- remote control systems - such devices are equipped with conventional remote controls.

Also on sale are ceramic fan heaters with splash protection - they are designed for use in wet rooms.

Devices with electric control more convenient for daily use. Even better if they are equipped with a remote control.

Another difference is in the type of management. Ceramic fan heaters for the home are equipped with electronic or mechanical type. Electronic systems have increased accuracy and extended functionality - they are able to accurately track the temperature, show its value on the screen and work in accordance with the programmed program. Simple mechanical thermostats are less accurate, but fan heaters with them have more affordable price- this is their big plus.

Where is the best place to buy a ceramic fan heater? We recommend that you familiarize yourself with indicative prices on "Yandex.Market" and visit large chain stores, which often have sales. The estimated cost of the simplest floor / desktop device with a power of 1.5 kW is approximately 1000-1200 rubles.

Device Security

Tall standing models are prone to falls, choose models with rollover protection.

What makes ceramic fans safe? The most important thing is their design, which includes safe heating elements based on ceramic plates. They also have overheating protection - it will not allow the equipment to fail due to exceeding a certain temperature.

The rollover protection system provides no less protection - it instantly turns off the heating element, preventing not only overheating of the equipment, but also the occurrence of fires (imagine what can happen if a working fan heater falls on the carpet and starts to slowly but surely heat it up - a fire may occur ). High vertical models have the greatest tendency to fall.

If you are planning to buy a ceramic fan heater, make sure you have both protection systems. Remember that your safety, the safety of your children and your property depends on them.

Do you plan to use a similar device for heating wet rooms– showers or bathrooms? In this case, we recommend looking at models with splash protection. They are safe for indoor use. increased level humidity and can withstand occasional small and large splashes.

Video "How to choose a ceramic fan heater"