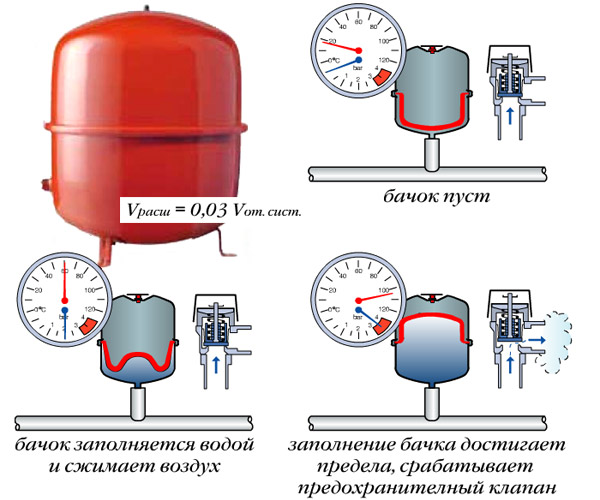

The heating system is very important element is an expansion tank for heating. Such a device serves to receive excess coolant at the moment when it expands, thus preventing rupture of the pipeline and taps.

Operating principle expansion tank for heating is as follows: when the temperature of the coolant rises by 10 degrees, then its volume increases by about 0.3%. Since the liquid is not burned, there is an excessive pressure that needs to be compensated. That's what the expansion tank is for.

Stainless hydropneumatic accumulators are used in installations drinking water, water wells, water tanks, natural sources. Drinking water, which we capture from the plant, is pulsated to the accumulator by the pumping plant.

When water enters the tank, it stays inside Bladder, which separates the air and water chambers. Introducing water into the tank reduces the initial volume of air in the tank and increases the pressure. When we reach the desired maximum pressure, the pressure switch cuts off the current and the water circulation between the pump and the tank remains interrupted.

Types of expansion tanks

V various systems heating apply different types expansion tanks. Previously, in systems without circulation pumps, an open expansion tank was used for heating. But such tanks had many disadvantages, so they are currently used very rarely. Due to the fact that air enters such an expansion tank for heating, corrosion appears, and the liquid evaporates faster and must be constantly replenished. Such a tank must be placed at the highest point of the heating system, and this is not always easy and simple to implement.

Depending on the needs of the users, the energy stored in the air in the tank delivers the water contained in the bladder to the points of consumption. As the water flows and the bubble empties, the pressure in the zone decreases to a minimum set pressure, after which the flow of water from the tank is restored.

This cycle will run automatically when the maximum and minimum pressures are reached. Maintenance will only be performed by authorized personnel. After installation, the battery works without problems. Maintenance is practically nil.

Open expansion tank for heating

In such heating systems, where the heat carrier circulates with the help of a pump, a closed expansion tank for heating is installed, the calculation here is that this is a sealed container that has an elastic membrane inside. The membrane (balloon or diaphragm) divides the tank into two parts. Air or an inert gas under pressure is pumped into one part, and the other part is intended for excess coolant. The membrane inside the tank is elastic, therefore, when the coolant enters there, the volume of the air chamber becomes smaller, the pressure in it increases, thus compensating high pressure in the heating system. On cooling, the reverse process takes place.

The only essential standard Maintenance is to check every 6 months for the presence of compressed air inside the tank. Also, make sure the tank has enough of water to prevent the bubble from sticking to the lid and causing damage.

When designing the bladder, sufficient dimensions were determined so that in the event of air loss, the bladder can occupy the entire volume of the container without damage to it. If necessary, the battery offers the possibility to easily replace the bladder.

The installation in which the hydropneumatic accumulator is to be installed must be equipped with a safety system that limits the pressure and ensures that the pressure does not exceed upper limit designs. Stainless and hot-dip galvanized tanks, both inside and out, equipped with all the necessary connections for all accessories and all the parts needed for a good installation.

The device of closed expansion tanks

Closed expansion tank for heating flat tank can be flanged (have a replaceable membrane) and with a non-replaceable membrane. The second type is in rather high demand due to the relatively low cost. But flanged expansion tanks are much better - the pressure here can be greater, and if the membrane breaks, you can replace it.

The tightness and strength of the tanks are tested at a pressure of 1.5 times the maximum operating pressure. Hydropneumatic, stainless or galvanized, bubble-free accumulators designed for potable water distribution systems. Working in parallel with the pressure group, they guarantee the minimum pressure for water distribution.

They not only accumulate water under pressure, but also extend the service life. pumping unit, dramatically reducing the number of pump stops while wasting less energy. As the water flows and the bubble empties, the pressure in the area is reduced to the minimum set pressure, after which the flow of water from the reservoir is restored.

The flange expansion tank of the heating system can be either vertical or horizontal.

Here, the liquid, when it enters the tank, does not have contact with metal surface because it is inside the membrane. If the diaphragm is damaged, it can be replaced through the flange.

When water and air remain in contact, pressure changes are compensated by running the compressor through the air jets. The tank can be equipped with a level system to check the water level inside the tank. Once the battery is installed, it will work automatically, so there is little to no maintenance. The only maintenance standard is to check and clean every 6 months the various accessories that are included in the tank.

They have an exchange bladder that contains water and prevents it from coming into contact with the steel. In the space between the bladder and reservoir we find gas. The inlet is equipped with a grid that has been specially designed to prevent damage to the bladder.

Vertical and horizontal flanged tanks

Tanks in which a replaceable membrane is not provided, it is fixed rigidly around the entire perimeter. The diaphragm is pressed against the inner surface from the very beginning, since the volume of the expansion tank for heating is completely filled with gas. After that, the pressure in the heating expansion tank increases, and the liquid goes inward. When the system starts up, the pressure can rise sharply, so it is at this point that the membrane can be damaged.

The hatch is located in the center of the curved bottom in the horizontal models and at the tip of the vertical ones. Internal protection with epoxy coating. These reservoirs should be installed in all plumbing systems to reduce the surge and depression waves caused by the large change in flow resulting from stopping or starting a pump.

When the pumps stop, we have negative pressure in the pipe. When the water column returns, it creates overpressure in a pipe that is damped by the gas contained in the antifreeze. This overpressure is limited valid value, which was established when calculating antifreeze.

Expansion tank selection

The choice of an expansion tank for heating is a responsible matter. In this case, it is imperative to pay attention not only to its type and size, but also to the membrane - such indicators are important: resistance to the diffusion process, operating temperature range, durability, compliance with sanitary requirements.

Thus, the installation of an anti-fog ball offers the following advantages. Increase the life of plants. Reduced installation costs. Reducing the pressure rating of pipes, valves, accessories. Protection and safety guaranteed. Anti-air balls are supplied with an initial pre-inflation of 0.3 bar. Following are the steps for correct installation fog ball.

Make sure the connection between pipe and cylinder is correct. Fill air through the installed valve. When the tank is equipped with water level checking equipment, proceed as follows. Open the valve and close the valve. Fill the air with a portable compressor or gas cylinder until the pressure on the gauge is slightly higher set pressure pre-inflation.

Today on the market there is a wide range of expansion tanks for heating systems.

In addition, it is necessary to determine the ratio of the boundaries of the pressure range, which is the maximum allowable. Be sure to check before buying a tank whether it matches existing norms quality and safety.

Set the pressure to the exact value by opening and closing the ball valve. Open the valve that isolates the cylinder from the unit. At this stage, if the rest of the installation is already supplied with water, static pressure injects water into the bulletproof ball. Open all level system keys and start the pump, allowing the station to run continuously. At this time, mark a stroke at the system level with the height at which the dot is located.

The correct counterdrill volume is calculated according to the line characteristics and the maximum and minimum allowable pipe pressures. Its lifespan is virtually unlimited as it does not suffer from dilatation effects. Aperture is calculated and measured so that it completely occupies inner surface tank if there is any air loss.

Tank volume calculation

First of all, let's determine the dependence of the required volume and the parameters that affect it. When calculating, it must be taken into account that the larger the capacity heating system and the higher Maximum temperature the heat carrier in it, the larger the tank should be. The higher the allowable pressure in the heating expansion tank, the lower it can be. Of course, the calculation method is quite complicated, so it is better to consult with a specialist. After all, a mistake in choosing an expansion tank can cause frequent operation of the safety valve or other troubles.

The tightness and resistance of tanks are tested at a pressure of 1.5 times its maximum working pressure. Final application epoxy paint on the surface of the phosphate. The tank operates from -10º to 100º. V heating installation when the water is heated, the water expands, increasing in volume, which creates dangerous situation when installing. The expansion vessels are responsible for compensating for this increase in water volume, thereby avoiding the pressure of the circuit from exceeding the pressure rating of its components.

Between the membrane and the tank wall we have a pressurized air cushion. When the reservoir is filled with water, the membrane pushes the air and compresses it. As the temperature of the water drops, the volume decreases and compressed air pushes the membrane back to its original position.

The volume is calculated using a special formula. Here, the main value is the total volume of coolant that is present in the heating system. This value is calculated taking into account the power of the boiler, the number and types heating devices. Approximate values: radiator - 10.5 l/kW, underfloor heating system - 17 l/kW, convector - 7 l/kW.

Before installation, make sure that the volume of the expansion tank has been calculated by authorized personnel. The expansion vessel must be installed between the boiler and mixing valve, preferably on the return pipe of the boiler. V closed system heating, in addition to the expansion vessel, we must install a safety valve and a pressure gauge. The safety valve must be fully adjusted according to the pressure of the boiler and the installation, not exceeding the maximum pressure in the vessel.

The closed expansion vessel must be installed in such a way as to avoid the formation of air layers. Heat sources near the vessel should be avoided to protect the membrane from excessive temperature. It is important to prevent the valve from closing by isolating the circuit from the expansion tank.

To make a more accurate calculation of a device such as a vacuum expander for heating, the following formula is used: Tank volume \u003d (Heating system water volume * Coolant expansion coefficient) / Expansion tank efficiency. The expansion coefficient for water is 4% when it is heated to 95 degrees. Another formula to determine tank efficiency is: Tank Efficiency = (Highest System Pressure - Initial Air Chamber Pressure) / (Highest System Pressure + 1).

Pressure air cushion should be checked every six months. We will check the pre-inflation valve to ensure that this pressure stays within the correct parameters. This test must be carried out at the same temperature to avoid pressure changes caused by temperature changes.

However, this pressure must be adjusted and adjusted according to the installation in which the vessel will operate. When filling the system with water, make sure that the pressure indicated on the manometer is slightly higher than the static pressure in the system. Maintain installation at maximum operating temperature for half a day. Remove air from the system by replacing it with water.

Expansion tank usable volume coefficients

Thus, the vacuum heating expansion tank is selected taking into account the characteristics of strength and temperature, which should not be higher than the permissible values at the connection point. The volume of the tank can either be equal to or greater than the result that was obtained as a result of the calculations.

Vases must be protected from climatological adversity. In order to prevent internal corrosion of the expansion vessels, it is advisable to purge the circuit at regular intervals. Fixed dilator vessels of the diaphragm do not have interior cladding. Therefore, they are not provided anti-corrosion protection as they are intended for exclusive use in closed atmospheric circuits with non-aggressive fluids. Any external air intrusion into the system must be kept to a minimum by maintenance.

Installing an expansion tank

Installation of the expansion tank of the heating system is done in accordance with the project and instructions. The best option it will be for you to have a specialist do it. If this is not possible, then at least consult with him. Installation of an expansion tank for heating, if it is open type, produced at the highest point of the heating system. closed tank can be placed almost anywhere, but not directly after the pump.

It is made of elastic rubber resistant to high temperatures calculated and calculated in such a way that it can occupy the entire inner surface of the tank without breaking. The vase is also equipped with a compressor and all the elements necessary to monitor, control the pressure and volume of water contained in the vase. All these elements will be shown on the display.

External protection, on a phosphated surface and painted in red. The increase in water volume caused by the rise in temperature is absorbed by the bladder, while the air between the bladder and the reservoir is expelled through the vent. Due to this reduction in air cushion, the tank can absorb an expansion volume equivalent to its total volume while maintaining pressure adjustable installation within a tolerance of 0.2 bar.

One of the installation options expansion tank into the heating system

Necessary Special attention pay attention to such an issue as fixing an expansion heating tank, since the mass of the tank, which is filled with water, increases significantly. Also important point- this is the possibility and convenience of servicing the tank, free access to it.

Compressor vase provides constant pressure for easy installation control. Team automatic control and controls are included in the vase, perfectly adjusted and ready to go. Its operation is automatic and does not indicate any maintenance.

The instruction manual shows the steps you need to follow when developing easily and quickly. Allows easy control and adjustment of the installation. Guarantees constant set pressure. Suitable for filling almost the entire working volume of the tank, saving space.

Expansion tank service

The role of such a device as an expansion tank of a heating system cannot be underestimated. The instructions for this device provide a list of rules for its maintenance. These include:

- Once every six months, it is necessary to check the tank for external damage - corrosion, dents, smudges. If suddenly such damage is found, then it is imperative to eliminate their cause.

- Once every six months, it is necessary to check the initial pressure of the gas space for compliance with the design indicator.

- Once every six months, the integrity of the membrane is checked. If a violation is found, it must be replaced (if such a possibility is provided).

- If the tank is not to be used for a long time, then you need to keep it in a dry place, draining water from it.

Next, how to check the heating expansion tank - its initial pressure of the gas space. To do this, disconnect the tank from the heating system, drain water from it, connect a pressure gauge to the gas cavity nipple. If the pressure is lower than that which was set at the same time when the expansion tank for heating was set up, the tank must be pumped through the same nipple with a compressor.

Manometer readings at correct work expansion tank

Checking the integrity of the membrane is also an important point. If suddenly while checking the pressure of the gas space after you have drained the water, through the drainage faucet goes air, and the pressure in the gas cavity has decreased to atmospheric - then the membrane is broken.

To replace the membrane, you need to go through several stages. First of all, the tank is disconnected from the heating system, then it needs to be drained. Next, the pressure of the gas cavity is released through the nipple. The membrane flange is dismantled. It is located in the area of \u200b\u200bthe branch pipe for connecting to pipes. The membrane included in the device of the expansion tank for heating is removed from the hole at the bottom of the housing.

Then you need to check the inside of the case so that there is no dirt and corrosion, if any, you need to remove them and rinse with water, then dry them. To remove corrosion, do not use products that include oils! The membrane holder is inserted into the hole at the top of the membrane. The bolt is screwed into the membrane holder, it is placed in the housing, and the holder is retracted into the hole in the bottom of the housing. Then the holder is fixed with a nut. After that, the membrane flange is placed on the body.

Content

Installing an expansion tank in the heating system ensures its performance and reliability. Devices of this type are used in open and closed systems, with gravity or forced circulation of the coolant.

Expansion tank functions

What is the purpose of the expansion tank? The heating system is filled with a fixed amount of fluid (water or antifreeze) that is prone to thermal expansion. This means that an increase in the temperature of the coolant inevitably leads to an increase in pressure in the system. Since pipes, radiators and other elements engineering design inelastic high blood pressure will lead to depressurization of the system - in the very weak spot a breakthrough will occur.

Water is different low scores compressibility, so the system is built special device- membrane or open tank. Its function is that when the pressure rises, air will be compressed. This makes it possible to provide protection against water hammer. The installed expansion tank protects the system from excessive pressure increase.

The main task is to fulfill reliable installation tank

For heating system closed type membrane tanks are designed - they are a container with an elastic waterproof membrane inside, which divides the internal volume into two parts. The membrane is needed so that air does not come into contact with the coolant. Otherwise, airing the network and increasing the risk of corrosion cannot be avoided. steel elements systems.

In an open type system, the tank communicates with the atmosphere, due to which air is bled from the pipes. For this reason, the installation location open tank strictly regulated - it should be located at the highest point of the system.

How to connect an expansion tank

How to make a reliable connection of the expansion tank in open system!? An open-type heating system is characterized by the fact that the movement of the coolant in it is ensured by convection.

The principle of operation is as follows: the coolant heated by the boiler unit is delivered directly to the highest point of the system, as a result of which it enters the heating radiators by gravity and, having cooled down, returns to the boiler through the “return” pipeline. There is always dissolved oxygen in water, which is released during convection, which means that air bubbles tend to rise up.

When considering this diagram, it becomes obvious that the only possible location for the expansion tank is the top point of the system. For single pipe system- it top part accelerating collector.

Wiring diagram membrane tank in an open heating system

Wiring diagram membrane tank in an open heating system As a tank, you can use any container of a suitable size made of a heat-resistant material. A cover (not sealed) is needed for it only to protect against debris entering the system. If a small metal barrel was not at hand, the tank is welded from sheet steel 3-4 mm thick.

The tank must be installed in compliance with certain rules, in particular:

- the tank must be placed above the boiler unit and connected by a vertical riser through which heated water is supplied;

- it is recommended to insulate the body of the tank to reduce heat loss, especially if the tank is located in an uninsulated attic at home.

Over time, the water from the tank evaporates and periodically it needs to be topped up. This can be done using an ordinary bucket. If the tank is installed in the attic, which is difficult to reach, a water supply pipe is brought to the tank installation site, and an emergency overflow is organized to avoid flooding the house hot water in case of emergency. The emergency overflow pipe is usually connected to sewer network, but owners of private houses often simplify the task by bringing it outside through a wall or roof.

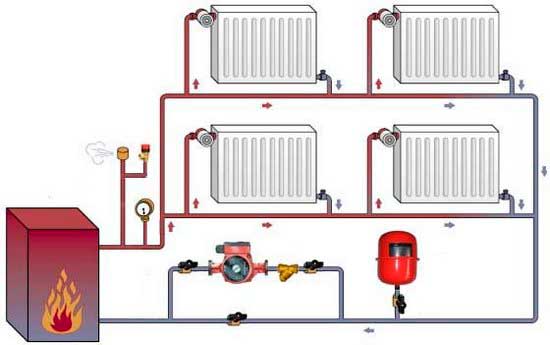

Expansion tank in a closed heating system

Equipment for the heating system is selected at the stage of its design, taking into account the requirements for the performance of the boiler unit, the length of the pipelines and the volume of the heat carrier involved. A scheme is being developed that indicates the installation locations of all elements of the system, including the expansion tank. In a closed type heating system, a membrane device must be used.

Expander in closed system heating

Expander in closed system heating When linking a project to an existing boiler house, it is important to take into account the following points:

- The tank should be placed in such a way as to provide normal access for installation and further maintenance. Floor models it is not recommended to install close to the wall.

- If the unit is mounted on a wall, it is advisable to place it at such a level that you can easily reach the air spool and shut-off valve. Usually the tank is placed under the ceiling of the room, only if it is not possible to mount it at a convenient height.

- The supply pipe must not be placed on the floor across the passage or suspended at human height.

- Pipelines connected to the expansion tank must be fixed to the wall. It is important to avoid a situation where the load from them and from stop valves lays on the tank pipes. Fixing pipes and taps separately for easy replacement expansion device in the event of its failure.

At the stage of equipment selection, it is necessary to calculate the required volume of the expansion tank. Minimum value given parameter is 1/10 of the total volume of fluid circulating in the system. It is acceptable to use a larger tank. But an insufficiently capacious tank can become a source of problems, as it is not able to compensate for the increased pressure in the system.

Expansion tank placement rules

Expansion tank placement rules For approximate calculations of the volume of coolant in the system, you can take as a basis thermal power boiler unit. On average, 15 liters of liquid per kilowatt are used. Accurate calculations are made taking into account the length of pipelines, the volume of radiators, etc.

Important! Many models of gas and electric boilers are mini-boiler rooms, that is, they are immediately equipped with a pump for forced circulation coolant, as well as an expansion tank. You do not need to purchase a separate tank if the parameters of the built-in membrane tank are sufficient to ensure the functionality and safety of the existing heating system.

When purchasing a membrane expansion tank, pay attention to whether the selected model has a safety valve, due to which excess pressure is automatically released. If this is not provided for by the design of the device, you should buy a safety valve separately and install it in the immediate vicinity of the tank.

Where is the best place to put the tank

The optimal place for mounting a membrane tank is a straight section of the pipeline, which is characterized by a laminar flow of water, that is, the absence or minimal amount swirls. Convenient place is the spill area near the circulation pump.

Note! Installation of an expansion tank of a closed-type heating system can be carried out at any convenient height. There is no need to place it at the highest point as it functions solely as a water hammer protector. Unlike an open-type heating system, the air accumulated in the pipeline is vented using special valves- air valves.

From a hydraulic point of view, it is best to install the membrane reservoir on the return line in such a way that circulation pump located between it and the boiler. In this case pump equipment will function in optimal mode.

Scheme of possible placement of the tank

Scheme of possible placement of the tank If desired, the tank can also be placed on the supply line, operational properties heating system will not be affected. But the membrane tank itself will last for a relatively short time, since the polymer membrane will constantly be in contact with the coolant, which has just been heated to 90 degrees, and not with water that has cooled to 45-60 degrees and returned through the pipeline.

Attention! Installing a membrane tank on the supply line is highly discouraged if the boiler is solid fuel. There is a risk that due to emergency the water in the boiler will begin to boil and steam will enter the tank. Water vapor, like air, is a compressible medium, due to which the membrane cannot compensate thermal expansion water.

Expansion tank installation process

Now let's figure out how to install an expansion tank in the heating system. Exists important rule connection of the device: the tank must be connected to the heating system mains using a cut-off ball valve with an American. This principle of installation makes it possible, if necessary, to block the movement of water in the system at any time, remove the faulty membrane tank and install a new one.

Otherwise, it would be necessary to wait for the coolant to cool down and dismantle part of the piping. Ideally, a tee is installed on the inlet, as well as a second tap - in this case, before removing the expansion tank, it can be emptied into a substituted container.

Hanging the expander upside down, if the membrane malfunctions, the unit will fail immediately

Hanging the expander upside down, if the membrane malfunctions, the unit will fail immediately How to correctly orient the membrane expansion tank in space? The tank is installed with the air chamber up or down, the tank is placed “on its side”. From point of view performance characteristics it does not really matter, since in any case the device will perform its functions properly.

However, it is worth considering this moment: if the air compartment is located below, then the coolant is supplied from above, and the bubbles of air dissolved in it will rise into the pipeline and be removed using an air valve. Otherwise, an air bubble will form in the "water" compartment of the membrane tank over time.

In turn, when the tank is located with the air chamber up, its service life is extended. Over time, from constant contact with hot water, the polymer membrane loses its tightness, cracks appear in it. If the air chamber is located at the bottom, then water immediately begins to seep into the air compartment, which will quickly disable the expansion tank, while air will penetrate into the coolant. When the air chamber is located on top, the diffusion of water through the cracks is many times slower, and the device is able to work much longer.

Helpful Hints:

- If you install a pressure gauge next to the expansion tank and the valve, which feeds the heating system from the water supply, it will allow you to control the pressure in the system in order to bleed the excess in time if the spool safety valve stuck and does not work automatically.

- The frequently repeated release of pressure by the valve indicates that the capacity of the expansion tank has been selected incorrectly. Instead of changing it to a larger tank, it is enough to connect a second tank in parallel.

- Replacing the existing expansion tank with a larger one or connecting a second one will also be required if it is decided to replace the water in the system with antifreeze. This is due to the fact that non-freezing coolants have a higher coefficient of thermal expansion.

If there is no pressure gauge, the expansion tank circuit should be equipped with a safety group

If there is no pressure gauge, the expansion tank circuit should be equipped with a safety group Setting

Before connecting the tank and filling it with coolant, you need to check the pressure level in the air chamber of the tank - it must correspond to the pressure in the heating system. To do this, remove or unscrew the plastic plug that closes the spool (similar to those installed in car chambers). Using a manometer, it is necessary to measure the pressure and adjust it to the indicators of the heating system. To do this, air is pumped up by the pump or vice versa, it is bled by pressing the spool rod.

Note! The tank should be set in such a way that the pressure in its air chamber is 0.2 bar less than the calculated pressure in the system filled with coolant. If the pear-shaped membrane is not pressed from the water injection side, the coolant, shrinking during cooling, will be able to draw air through.

After completing the settings, open the tap and fill the entire system with coolant. Then the boiler unit is started.

The adjustment step is not required if the factory pressure in the air compartment of the expansion tank corresponds to necessary parameters. Manufacturers of some brands of equipment indicate the level of pressure in the tank on the packaging, which makes it possible to choose the option that will be optimal when buying.

Conclusion

You can correctly install the expansion tank, prepare a customizable membrane tank for work yourself, without the help of a specialist. The experience gained can be useful in the future if you need to quickly identify the source of problems associated with a decrease or surge in pressure in the system, due to which the burner flame goes out. In such cases, it is recommended first of all to carefully inspect the system for coolant leaks and measure the pressure in the air chamber of the membrane tank.