A heating gas boiler is a device that, by means of the combustion of fuel (natural or liquefied gas), heats the coolant.

The device (design) of a gas boiler: burner, heat exchanger, thermally insulated housing, hydraulic unit, as well as safety and control devices. Such gas-fired boilers require a chimney to be connected to remove combustion products. The chimney can be either a conventional vertical or coaxial (“pipe in pipe”) for boilers with closed camera combustion. Many modern boilers equipped with built-in pumps for forced circulation of water.

The principle of operation of a gas boiler- the coolant, passing through the heat exchanger, heats up and then circulates through the heating system, giving the received thermal energy through radiators, underfloor heating, heated towel rails, as well as providing water heating in the boiler indirect heating(if it is connected to a gas boiler).

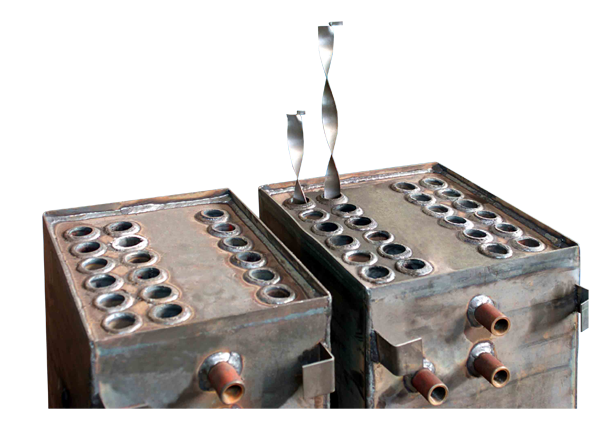

Heat exchanger - a metal container in which the coolant (water or antifreeze) is heated - can be made of steel, cast iron, copper, etc. The reliability and durability of a gas boiler depends on the quality of the heat exchanger in the first place. Cast iron heat exchangers are corrosion resistant and have long term services, but are sensitive to sudden temperature changes and are distinguished by significant weight. Steel containers can suffer from rust, so they internal surfaces protect with various anti-corrosion coatings, providing an extension of the "life" of the device. Steel heat exchangers are the most common in the manufacture of boilers. Corrosion is not terrible for copper heat exchangers, and due to the high heat transfer coefficient, low weight and dimensions, such heat exchangers are often used in wall-mounted boilers, but of the minuses, it should be noted that they are more expensive than steel ones.

In addition to the heat exchanger, an important part of gas boilers is a burner, which can be of various types: atmospheric or fan, single-stage or two-stage, with smooth modulation, double.

To control the gas boiler, automation is used with various settings and functions (for example, a weather-compensated control system), as well as devices for programming operation and remote control boiler.

The main technical characteristics of gas heating boilers are: power, number of heating circuits, type of fuel, type of combustion chamber, burner type, installation method, pump and expansion tank, boiler control automation.

To determine required power gas heating boiler for private country house or apartments used simple formula- 1 kW of boiler power for heating 10 m 2 of a well-insulated room with a ceiling height of up to 3 m. If heating of a glazed basement is required winter garden, rooms with non-standard ceilings, etc. the gas boiler output must be increased. It is also necessary to increase the power (about 20-50%) when providing a gas boiler and hot water supply (especially if water heating in the pool is necessary).

The peculiarity of calculating the power of gas boilers: the nominal gas pressure at which the boiler operates at 100% of the power declared by the manufacturer, for most boilers is from 13 to 20 mbar, and the actual pressure in gas networks in Russia can be 10 mbar, and sometimes even lower . Accordingly, a gas boiler often works only at 2/3 of its capacity, and this must be taken into account when calculating. In more detail with a table for calculating the power of a heating boiler, you can

Most gas boilers can switch from natural gas operation to liquefied gas (ballooned propane). Many models switch to liquefied gas at the factory (check these characteristics of the model when purchasing), or nozzles (jets) are additionally supplied to the gas boiler to switch to bottled gas.

Pros and cons of gas boilers:

Boiler piping- These are devices for the full operation of the heating and water supply system. It includes: pumps, expansion tanks, filters (if necessary), manifolds, check and safety valves, air valves, valves, etc. You will also need to purchase radiators, connecting pipes and valves, thermostats, a boiler, etc. The issue of choosing a boiler is quite serious, so it is better to entrust the selection of equipment and its complete set to professionals.

What is the best boiler? On the Russian market gas boiler equipment has its own leaders in quality and reliability. The best manufacturing companies and brands of gas boilers are presented in the range:

"Premium" or "Lux"- the most reliable and durable, easy to manage, the kit is assembled as a "constructor", more expensive than the others. These manufacturers include German companies

The purchase of a gas boiler requires a rigorous choice, since the comfort of being indoors in the future depends on this investment in equipment. A gas boiler is bought for a long time, so the choice of a gas heating boiler must be thought out to the smallest detail.

Price groups of heating equipment

If we divide all the equipment into conditional groups based on the price, then they will simultaneously reflect:

- quality;

- reliability;

- durability;

- comfort;

- profitability;

- functional features equipment.

Heating boilers on the sales market are classified according to:

- removal method flue gases;

- installation method;

- material;

- the number of contours;

- fuel;

- power;

- productivity;

- price.

How to choose gas boilers heating, based on these main groups, we will now tell.

The leaders of heating technology are German equipment, in more detail:

- Boilers and boilers: Vaillant, Wolf, Buderus and Viessmann;

- Pumps for hot water and heating systems: Wilo, Pedrollo, Grundfos;

- Heating radiators: Kermi ;

- Chemical water treatment: Grunbeck ;

- Fittings, pipes, security systems: Oventrop.

Price heating boiler depends on its type, power, type of burner, as well as automation. The approximate price of the "German" is calculated by the formula: thirty-five euros per unit of boiler capacity.

When trying to separate boilers by price, three groups are distinguished:

- cheap boilers - representatives of domestic products;

- average price group quality equipment firms such as Ferroli, Dakon, Eleko, Roca, Rinnai;

- expensive price group, the highest quality equipment mainly from German brands (Viessmann, Wolf, Buderus, Vaillant).

Photos of all boilers of the above brands can be easily found on the World Wide Web.

The main parameters of gas boilers

1. Power.

This is the main parameter of the boiler. This parameter indicates how much area the boiler can heat.

Boilers of various capacities are manufactured: from a couple of kW to MW. Thanks to this, it is possible to optimally choose a boiler, both for heating the whole village, and for only one house.

How to choose a gas heating boiler for your home, you can find out by consulting with sales managers in any heat engineering store.

2. Fuel.

There are many types of boilers that can work on:

- gas (liquefied or natural);

- liquid fuel (mainly diesel fuel);

- solid fuel (coke, firewood, coal);

- electricity.

Any of these types of boilers can be ideal for you, it depends on the conditions of its operation. An instruction manual is included with each boiler.

Note!

Speaking of manufacturers, it can be noted that all German companies manufacture boilers for solid fuel, liquid and gas (Buderus, Viessmann, etc.).

But there are firms that specialize in the production of only one type of boiler, for example, electric (Eleko). But there are companies that produce boilers for all types of fuel.

3. Number of circuits.

A boiler that works only for the needs of heating the house is called a single-circuit. In the event that the boiler provides the needs of hot water supply, then it is considered to be a double-circuit one.

The type can be with a built-in boiler or flow type.

Advice. By connecting an ordinary boiler to an ordinary single-circuit boiler, you can get hot water for domestic needs.

All are equipped with automation systems and can provide quality work for other circuits, e.g. underfloor heating, ventilation, etc.

In order to choose the right boiler for your home, you need to systematize all the information received above.

First you need to define heat loss at home and, as a result, the required boiler power. Next, you need to decide on what type of fuel the boiler will operate on, and what kind of fuel will be rational to use in your case.

Perhaps you need to think about the use of water treatment.

We determine the required power of the heating boiler

It should be noted right away that it is best to entrust the determination of the boiler power only to heating engineers. Although this can be done with your own hands, but for this you need to calculate everything well.

For reference! To determine the power, you can use the ratio: 10 square meters are equal to one kilowatt of boiler power, subject to good thermal insulation and a ceiling height of three meters.

Of course, if you have a poorly insulated house, then you will need a powerful boiler. In addition, it must be taken into account that if it is possible to heat hot water, the required power must be increased by forty or even fifty percent.

The need for hot water is not constant, it is needed only at certain hours. Therefore, the heat supply system is designed taking into account these needs, and priority is given to water heating.

While the boiler is working to heat domestic water, it stops heating water for the heating system. Practice shows that during the heating of water for hot water supply, the heating system does not suffer, and the temperature in the rooms does not change.

In the event that the boiler will be used to heat water in other places, for example, in a pool, then this must also be taken into account.

It should be borne in mind that in cases of installing gas boilers, in their instructions, the manufacturer writes the characteristics for the nominal gas pressure. Since the pressure in gas supply systems is much less than the nominal pressure, the boiler has much less power in practice.

Types of boilers and their choice

In the event that a gas supply is connected to your site, then in most cases a gas boiler will be the ideal choice for you. A gas boiler is cheaper than its counterparts on other types of fuel.

gas boilers

Gas boilers with atmospheric burners are divided into two types:

- wall;

- floor.

Heat exchangers for floor boilers are usually made of two materials: steel and cast iron.

It is impossible to say with certainty that some material is better, each has its own advantages and disadvantages.

Steel heat exchangers are lighter than their cast iron counterparts, they are not afraid of shock during transportation and unloading.

Heat exchangers made of cast iron are thicker than steel ones. This has a positive effect on their service life. However, cast iron is a very brittle material.

Practice shows that great importance for the service life, in addition to the choice of heat exchanger material, it is provided by a properly manufactured project, high-quality installation and operation.

Wall-mounted boilers are also called "mini boiler rooms".

Relatively in a small boiler body, it is located:

- burner;

- Control block;

- heat exchanger;

- circulation pump;

- manometer;

- expansion tank;

- thermometer.

This equipment provides high quality and safe work boiler.

According to the method of removing flue gases, boilers are divided into models with forced circulation and natural attraction.

In models with forced circulation, a fan is installed that outputs flue gases outside the premises. This option is good for those rooms that do not have chimneys. In this case, it will be enough to make a hole in the wall.

In the event that the main gas pipeline is not connected to your house, then you should pay attention to:

- solid fuel boilers;

- boilers running on gas and liquid fuels;

- electric boilers.

Electric boilers

This type of boiler has many advantages:

- environmental friendliness;

- noiselessness;

- no need for a separate room;

- no chimney needed

- ease of operation;

- security;

- has a low installation cost;

- low cost the boiler itself.

The electric boiler is very simple device. It consists of a heat exchanger, which is a tank, inside of which there are heating elements, as well as a control and regulation unit. A video about the boiler device can be found on the Internet.

Some firms make electric boilers already with filters safety valves, expansion tanks and circulation pumps.

Electric boilers of small power are made in two versions:

- single-phase;

- three-phase.

Single-phase boilers operate from a network with a voltage of 220 Volts, and three-phase from a network of 380 Volts.

Boilers with a power of more than 12 kW are made only for 380 Volt networks. Most of these boilers with a power of not more than 6 kW are made multi-stage, which makes it possible to rationally use electricity.

Disadvantages of electric boilers:

- not every site has an appropriate electrical network;

- expensive electricity.

Oil boilers

Boilers equipped with liquid fuel burners provide complete autonomy of your home from external factors.

You will not be dependent on natural gas supplies. And if you install additional source power supply, then you will be independent from the mains. The only thing you need is the timely delivery of liquid fuel (diesel).

Boilers with replaceable burners are easy to operate. And if there is no pipeline with natural gas near your site yet, then it may appear in the future, but for now the boiler will be able to function with a liquid fuel burner.

It should be taken into account that the price gas burner can be very high and reach the cost of the boiler itself. This is explained by the fact that such burners are technically complex and provide high efficiency. The latter can be 94%.

Solid fuel boilers

Coke, hard and brown coal, as well as ordinary firewood can serve as fuel for such boilers.

Both models are made that work on all these types of fuel, and on some one. The latter have an efficiency higher than that of the first type of boilers.

For some reason, at the mention of solid fuel boilers, people imagine primitive devices that do not have automation. This opinion is categorically not true, since in our time a lot of boilers are simply “stuffed” with various automation.

Almost all boilers of this type automatically maintain the set outlet temperature. This is due to a sensor that monitors the temperature of the coolant.

This sensor is connected to the damper and when the water temperature becomes higher than the one you set, the damper closes and the combustion becomes less intense. Conversely, when the temperature is low, the damper opens.

New solid fuel boilers easy to use when compared with its predecessors. But there remains one significant drawback. Such boilers cannot operate in a fully automatic mode, they still need the presence of a person who will throw fuel into the boiler from time to time.

Boilers for three or more types of fuel

You can often find boilers in stores that are equipped with a combustion chamber. solid fuel, as well as having the ability to install mounted burners for liquid fuel and gas.

Such boilers are convenient when there are interruptions in the supply of natural gas or when there is no natural gas at all.

There are companies on the sales market that produce boilers that have two separate combustion chambers. One chamber for gaseous and solid fuels, and the second with a built-in heating element.

Such boilers work on all types of fuel. But it is impossible to say with certainty that such universalism is not needed. Since the price of such boilers will be much more than conventional gas boilers, and you will not use all types of fuel.

Double-circuit boiler or single-circuit

In the event that the need for hot water is small (within 10-15 liters per minute), then it is advisable to use a double-circuit flow-type boiler.

If the need for hot water is about 120 liters per minute or more, then it is best to install a boiler with a built-in boiler. The advantage of such a boiler is a large supply of water that can be used at any time, as well as a supply of hot water when the fuel supply is cut off.

But you have to pay a lot for such comfort, and such boilers also have disadvantages. These are bulky dimensions and weight, as well as low maintainability compared to simpler boilers.

In case you need high flow hot water and you have many taps that work at the same time, for example, showers, jacuzzis, bathrooms. That good way out From this situation, there will be a connection to your boiler of a large volume boiler of two hundred liters.

Such a boiler is connected to single-circuit boilers, as well as to double-circuit ones. This solution to the problem guarantees the availability of hot water all the time. How to choose gas heating boilers to work in such symbiosis with boilers, heating engineers can help you.

Summing up

Choosing a boiler is a complex process that requires a detailed analysis of your needs, location and energy supply, house analysis, etc.

Installation of gas boilers is the most perfect option, because they are much cheaper than their counterparts on other types of fuel; quite economical; do not require the constant presence of a person, that is, they are fully automatic; not whimsical in operation and others.

For large hot water needs, the best option will put the boiler. And if the water needs for hot water supply are small (up to 20 liters), then it is better to buy a double-circuit boiler.

Thanks to this article, we think that the question has been fully revealed to you: “How to choose a heating gas boiler?”. But which option you choose is up to you.

1.

2.

3.

4.

While creating autonomous system gas boilers are widely used for heating. They have some advantages that make their use more appropriate than equipment powered by electricity or gas fuel. There is a lot of doubt about which gas boiler to choose.

Since the market has wide range of heating appliances, there is often a problem with how to choose a gas boiler for the home so that it works efficiently and for a long time.

The main selection criterion is the power of the equipment - 1 kW is required to heat 10 "squares" of the area of the house. But such a calculation is considered approximate, since it does not take into account other factors:

- quality of insulation;

- the number of windows, doors, the material from which they are made;

- ceiling height;

- the climate of the region.

As for how to choose a gas boiler for your home, you need to pay attention to such points:

- power supply stability;

- need for hot water domestic use;

- the presence of a free channel for the chimney;

- location and size of the boiler room.

Which gas boiler to choose from the possible types

According to the installation method, gas boilers are wall-mounted and floor-mounted. Which gas boiler to choose depends largely on the area of \u200b\u200bthe room in which it will be installed. Both options are able not only to heat the house, but also to heat water for the needs of its residents.Wall-mounted boilers are more economical, they take less space. They usually have an expansion tank. The chimney can be natural or forced.

If a device with forced removal of combustion products is used, then in ventilation system at home, you do not need to create a separate channel. In this case, a branch pipe is attached to the boiler, which is then brought out through a hole in the wall. Such devices have two modes of operation: winter and summer. IN summer mode The boiler only works to heat water.

Which gas heating boiler to choose also depends on the power supply of the house. The fact is that wall devices in the absence of electricity stop working. So, if there are often interruptions in the power supply of the site, then it is better to buy a floor unit that does not depend on electricity. For its installation, a separate room of sufficient area is required (read also: "").

Single-circuit and double-circuit boilers: how to choose

Gas heating equipment It is available in single and double sided. As for how to choose a gas heating boiler, it is necessary to decide whether it is necessary to heat the water or not. If the device is bought only for heating, then a single-circuit boiler is needed (read also: ""). If it will also be necessary to heat water for domestic needs, then double-circuit equipment will be required.Double-circuit gas boilers are of two types:

- flowing;

- with built-in boiler.

Gas floor boilers: how to choose

Often there is a problem with how to choose the right gas boiler. Therefore, the advantages and disadvantages of floor and wall devices should be considered.Advantages of floor boilers:

- simple, but reliable and durable automation;

- lack of dependence on electricity - this is important if there are frequent power outages;

- The efficiency is about 90%.

- takes large area;

- a separate channel is required for the chimney;

- problems with hot water.

Gas wall-mounted boilers: selection

To understand how to choose a gas boiler for your home, you need to consider the characteristics of wall-mounted equipment - it is also convenient to use.Wall-mounted boilers are equipped with a special pump to improve water circulation through pipes and heating batteries. They also have an expansion tank and an automatic gas supply and safety control system. With their help, you can easily not only heat the house, but also heat the water. These devices are installed on the wall, which saves space (details: "").

The main disadvantage of wall-mounted boilers is the dependence on electricity. It is precisely with this that the limited distribution of such equipment is connected - outside the city, problems with electricity are common. That is why it is important to understand how to choose a gas boiler according to the area of \u200b\u200bthe house.

As for how to choose gas heating boilers, you need to decide on the type of ignition, which can be of two types:

- piezoelectric;

- electric.

Units operating with natural draft have an open chamber for gas combustion. For the full operation of such devices, a properly made chimney and inflow into the room are required. fresh air.

Equipment with a closed combustion chamber have forced system removal of natural gas combustion products. To do this, a fan is installed in the boiler that removes the spent fuel. Air in such devices also enters from the outside.

Automatic system regulation and safety serves for:

- regulation of the gas supply depending on the air temperature outside, thanks to which the house is maintained comfortable temperature, and gas is saved;

- you can set the heating output by the hour, for example, more at night than during the day, or vice versa. For example, if no one is at home during the day, then the air temperature can be slightly lowered, thereby saving on natural gas. Or, for example, during the day it is already quite warm outside, and by night the temperature decreases - then it is more reasonable to set the device to partial power during the day.

The selection of a gas boiler should be carried out taking into account many parameters: power, design (wall or floor), type of ignition, the presence of one or two circuits. It is impossible to say which model is the best - it all depends on the needs of the residents of the house (more: ""). It is important to remember that gas boilers are dangerous devices, so only specialists should be involved in their installation and connection.

Video tips on which gas boiler to choose:

When going to the store to buy a gas boiler, we often look for suitable models on the Internet using product catalogs. There are a lot of boilers on sale, they are designed for various conditions operation and on houses of various sizes. It is not so easy to understand all this diversity, and some sellers, instead of helping to make right choice only exacerbate the situation. Therefore, we decided to teach you how to understand gas boilers so that you can buy the most suitable model.

In this review, we will discuss:

- The main types of gas boilers;

- The internal structure of the equipment;

- Calculation of equipment power.

In the end, we will touch on our favorite user reviews.

Types of gas boilers

If you are going to buy a gas boiler, you need to imagine how the future heating system will look like or how it looks on this moment. You may want to purchase a versatile two-circuit model or replace a floor-standing unit with a wall-mounted unit to free up some space in your home. You need to understand that the differences do not end there.

Entering the store, we will find that there are modifications with open and closed combustion chambers, with various types heat exchangers, with one or another automation, with different capacities of hot water circuits and many other gas boilers. Available for sale as the most simple models, costing one and a half ten thousand rubles, and more expensive samples, for which you will have to fork out a lot or take a loan. Let's look at the most basic differences.

Boiler mounting options

Wall models are ideal for houses in which there are no boiler rooms.

To begin with, we will highlight the two most basic categories of gas boilers that we can buy in the store. This wall and floor models . Wall units are hung in separate rooms, in bathrooms or directly in the kitchen. If you have ever seen a common geyser(instantaneous water heater), then you will understand what this equipment looks like. It hangs directly on the wall, allowing you to free up space on the floor for something else.

Floor models of gas boilers, which can be bought at almost any store, are most often mounted in separate rooms allocated as boiler rooms. However, nothing prevents them from being mounted in a free corner of the kitchen, in the hallway or in the basement - the main thing is that there is an air flow here, since most floor lamps (especially the simplest ones) are equipped with open combustion chambers.

Advantages of wall installation:

- Significant space savings - wall modifications are more compact;

- It is possible to combine the heating system and hot water preparation- for this it is enough to buy a wall-mounted double-circuit gas boiler;

- Convenient control - the wall-mounted boiler is always in sight;

- Due to the high suspension, the equipment is easier to repair and maintain.

But floor units may be more powerful. And they are equipped with hardy cast-iron heat exchangers, which have a number of advantages over their steel and copper counterparts.

In the course of the overhaul people are increasingly changing floor standing wall models. But the first ones do not leave their leadership positions due to their simplicity and reliability.

Single and double circuit boilers

When using devices with a single circuit, you will have to buy additional optional equipment for the organization of hot water supply.

Single-circuit gas boilers are the simplest units that can only be bought in specialized stores. They work exclusively with a coolant, not allowing hot water to be prepared.. Therefore, they are much simpler and cheaper than their double-circuit counterparts. As for hot water supply, it is implemented in the following ways:

- By installing an electric boiler in the house;

- By connecting an indirect heating boiler to a single-circuit boiler;

- By installing a separate instantaneous water heater running on gas.

That is, we need to buy not only a gas boiler, but also auxiliary equipment which will organize hot water supply. This approach will certainly lead to the complication of the in-house device, but it has advantages - separate equipment is easier to repair and maintain.

In order to combine heating and water heating equipment, double-circuit gas boilers were created. They are not uncommon, they can be bought at any store selling plumbing and heating equipment. Double-circuit models are built on the basis of separate or combined heat exchangers. As a result, the heating system is filled with hot coolant, and flow from the tap hot water .

Using double-circuit gas boilers, you get both heat and hot water.

Double-circuit gas boilers are much more complicated than their single-circuit counterparts. Having removed the front cover, we can only be surprised at the abundance of various modules - here you can see circulation pumps, security groups, various sensors, gas units, devices for forced smoke removal and other not very clear things with wires and tubes. central part is occupied by a volumetric burner with a heat exchanger installed above it.

Gas boilers with separate heat exchangers are even more complicated - the second heat exchanger is hidden at the bottom of the equipment, responsible for preparing hot water.

Let's see which gas boiler to choose and buy in the store. On the one hand, one could recommend buying single circuit units. They are reliable and simple, but for organizing hot water supply, additional equipment is required - this is a water heater or boiler. As for dual-circuit models, they allow you to kill two birds with one stone at once.

The undoubted advantage of double-circuit gas boilers is that they significantly save space, combining not only the two necessary household appliances (boiler and water heater), but also the piping - as a rule, there are already air vents, safety valves, circulation pumps and expansion valves inside. tanks.

What to look for when choosing

Let's see how to choose a gas boiler for other reasons. We have already found out that they are single-circuit and double-circuit, as well as wall and floor. But the differences do not end there - there are even more of them inside, and they are more critical in choosing. Therefore, before you buy any model, read the details - they are very important.

Heat exchanger material

Now we will tell you how to choose a gas boiler, focusing on the materials of the heat exchangers. They are of three types:

- Cast iron - one of the most reliable, powerful and enduring;

- Steel - nothing can overtake them at a low cost;

- Copper - good option, which is reliable.

Cast iron heat exchangers are installed in floor gas boilers. And it is they who make them incredibly heavy, since cast iron is a very heavy alloy. It is resistant to corrosion, heats up quickly and cools slowly, but it has one serious drawback - cast iron is very brittle. Therefore, the installation of gas boilers with such heat exchangers should be carried out with the utmost care.

Steel heat exchangers are very light, cheap, but not the most reliable. Today, they are equipped with the cheapest models of boilers - these can be bought at any store. Experts and users note that such heat exchangers often leak, since the metal is made very thin. Also, scale settles on them better, which does not improve their technical characteristics in any way.

Copper heat exchangers are a kind of compromise between cast iron and steel. Copper is relatively light, it easily tolerates overheating and does not crack under accidental impacts. If you want to buy any gas boiler, be sure to make sure that it has a copper or cast iron heat exchanger are the best options.

Please note that copper heat exchangers are most often attributes of wall-mounted equipment, while cast iron is most often found in floorstandings. By the way, it is on the basis of cast iron that the most powerful gas boilers are built - in order to buy such equipment, you will need a lot of money.

If you want to buy a double-circuit gas boiler, we recommend paying attention to devices with separate heat exchangers - one of them heats the coolant, and the second prepares hot water. Yes, such a system is more expensive, but scale does not form here, since in the secondary exchanger heating is carried out using part of the coolant sent here through a three-way valve.

Models with combined heat exchangers are cheaper, but they quickly become clogged with scale and have extremely low reliability. As much as you would like to buy a cheap model with a combined heat exchanger, try to find extra money and buy a more expensive, but more reliable model with separate heat exchangers (for example, a copper primary and steel plate as a secondary).

Burner, boiler power and ignition method

Scheme of the device of boilers with open and closed combustion chambers.

In plumbing and heating stores we can buy the following gas boilers:

- With open combustion chambers;

- With closed combustion chambers.

The first are the simplest, here the air is taken directly from the atmosphere, and the removal of combustion products is carried out through a conventional chimneygoing to the roof. In connection with this design, in the room where the boiler is placed, there must be a good air flow.

Recently, consumers tend to buy gas boilers with closed combustion chambers - they are more expensive, complex and a little noisy, but they do not require the presence or installation of an expensive chimney (relevant when building a new house). Smoke removal, as well as the intake of air necessary for combustion, is carried out through a special coaxial double chimney, which is laid behind the nearest wall.

Let's take a look at how to choose a gas boiler according to the type of combustion chamber. If your house (apartment) already has a chimney, you can save some money and buy a model with a conventional combustion chamber. If there is no ready-made chimney, or you want to install the equipment in a room without a normal supply of fresh air, we recommend buying a model with a closed combustion chamber - you just have to bring the coaxial chimney outside.

If you are going to buy a gas boiler, please note that models with an open combustion chamber are called “atmospheric” in everyday life, and “turbocharged” with closed combustion chambers. The latter are noticeably noisy, as they are installed powerful fans. The main advantage of "atmospheric" devices is that they can work without electrical network(note, not all).

When planning to buy a particular gas boiler, it is necessary to pay attention to the power of the equipment - it must correspond to the characteristics of the heated building and the presence / absence of heat losses. The heating system should warm up all the rooms as efficiently as possible, because if the boiler does not have enough power, an increase in the number of sections in the batteries will lead to nothing but waste. How to choose and buy equipment with required power– we will tell in one of the following sections.

For greater safety, choose gas boilers with electric ignition.

Let's look at the types of ignition - in the store we can buy gas boilers with piezoelectric or electric ignition. The former work on the basis of a constantly burning fuse, which is ignited using a piezoelectric element. I.e, gas is constantly burning in the apparatus, which in itself is unsafe.

If we buy an apparatus with electric ignition, we will have at our disposal a boiler in which there will be no constantly burning fuse. Here the burner is ignited by a high voltage electric spark. In non-volatile units, the power source for the spark generator is two batteries.

Boiler automation

For problems with automation gas equipment trust its repair to professionals.

If you want to buy a good gas boiler, make sure that it has good automation. It must provide:

- Monitoring the safety of equipment and surrounding people ( gas leakage protection, flame detection, water and gas pressure monitoring);

- Smooth temperature control in the DHW circuit (provided by smooth electronic modulation);

- Exact adherence to the specified parameters.

More expensive boilers are able to work according to a given schedule, control the system by the temperature of the coolant and indoor air, and are guided by the weather outside the building using special outdoor sensors. For more convenient control, you should choose and buy a device with the ability to connect room thermostats and remote controls.

In the simplest non-volatile double-circuit boilers established mechanical systems management, but even they know how to control all the most required parameters(Including they care about the safety of those around them).

Boiler power calculation

When choosing the power of a gas boiler, it is necessary to focus on the standard formula, based on which per 10 sq. m. of heated area requires 1 kW of thermal energy. In other words, for a household of 100 sq. m. you will need to buy equipment with a capacity of at least 10 kW (it is also necessary to leave a margin for heat losses and for the equipment not to work on its own peak power). We also pay attention to performance during the purchase process. DHW circuit:

- Up to 11-12 l / min - enough for one draw-off point;

- Up to 17 l / min - enough for two points at once.

Detailed scheme for calculating the power of a gas boiler.

Please note that the performance of the DHW circuit also depends on the temperature to which the water will be heated (for example, 20, 30 or 40 degrees from the initial temperature).

Approximate prices for gas boilers

The sale of gas boilers is carried out in almost all plumbing stores and heating engineering stores. There are a lot of them, if necessary, you can purchase one or another device under the order. Largest Choice you will find in online stores. Before you buy equipment, you should familiarize yourself with the prices of gas boilers. Here is an approximate price range:

In spite of wide choose gas boilers, try to choose equipment from well-known manufacturers.

- Single-circuit floor-standing with an open combustion chamber - from 6.5 thousand rubles;

- Double-circuit floor with an open combustion chamber - from 10 thousand rubles;

- Single-circuit wall-mounted with an open chamber - from 18 thousand rubles;

- Double-circuit wall with an open chamber - from 19 thousand rubles;

- Single-circuit floor with a closed chamber - from 64 thousand rubles;

- Double-circuit floor with a closed chamber - from 64.5 thousand rubles;

- Single-circuit wall-mounted with an open chamber - from 18.3 thousand rubles;

- Double-circuit wall-mounted with a closed chamber - from 27 thousand rubles.

Imported devices are much more expensive, it is preferable to buy exactly imports, since neither consumers nor specialists praise domestic units. famous brands– BAXI, Buderus, Protherm, Vaillant and Bosch.

By the way, some boilers are under foreign trademarks are assembled in Russia under the control of the official brand - thanks to this they can be bought for less money. But we do not recommend buying products assembled in China - the chance to buy a not the most durable device is too great.

Basic principles for choosing a gas boiler

According to statistics, gas for heating in our country is used by more than half of the population. After all, this is the most cheap look fuel, which has numerous advantages over other energy sources. Therefore, it is not surprising that they are so in demand. AND modern market gas equipment is saturated with a wide variety of models. They differ in levels of functionality, so that a simple consumer may have difficulty choosing a gas boiler.

Varieties of boilers

Before buying a boiler, you should understand the sea of offers of gas devices, in their technical specifications, device and principle of operation.

All units operating on gas are divided into:

- According to the location - on the wall and floor.

- According to the material of the heat exchanger - steel and cast iron.

- By the number of circuits - single-circuit and double-circuit.

- By type of gas burner - with an atmospheric or inflatable (fan) burner.

- According to the principle of movement of the coolant - with natural or forced circulation.

- According to the ignition method - with a piezoelectric element or electric ignition in automatic mode.

- According to the method of removal of combustion products - with natural or forced draft.

- According to the type of combustion chamber - with an open or closed chamber.

- By .

- By presence or absence automatic control and some other parameters.

Important! If gas equipment is selected floor type, then it will require a separate room with an area of at least four square meters with a chimney, ventilation and a separate exit to the street.

In addition, the premises must have:

- Ceiling height 2.5 m.

- Width front door at least 80 cm.

- A chimney that exits through the roof and roof, located at least 0.5 m above the ridge level and having a minimum of bends and elbows. In addition, the internal clearance of the pipe must not be less than the diameter of the outlet of the gas boiler.

- The distance of the boiler from the walls is 0.3-0.5 m.

When gas is burned, smoke is formed, having a temperature of up to +120 degrees. In addition, sulfur dioxide, carbon dioxide, water vapor and other chemical compounds cooling in the chimney at a certain height.

The dew point, that is, the cooling point of the combustion products, is at around +55 degrees, which corresponds to 4-5 meters in height of the pipe. As a result of the formation of such a point, the cooled aggressive chemical compounds settle on inner walls chimneys, gradually destroying them. Therefore, it is recommended to arrange chimney channels from galvanized sheet - less susceptible to such substances and corrosion.

Wall mounted boilers

Gas wall-mounted boilers

Modern wall boilers do not require a separate room. They can be located in the kitchen or anywhere else in the house thanks to coaxial chimney horizontal orientation, which can be displayed through any outer wall building.

Such devices have in their design everything that should ensure its effective operation:

- burner.

- Heat exchanger with one or two circuits.

- Expansion tank.

- Circulation pump.

- Pressure gauge.

- Automatic security system.

- Thermometer.

However, choosing wall unit, it must be remembered that its power does not exceed 24 kW. In addition to wall-mounted devices, new gas-fired condensing boilers with pulsed combustion have appeared.

Heat exchanger material

Viadrus cast iron heat exchanger

Heat exchangers are made of steel or cast iron. Cast iron is almost twice as heavy and requires care during transportation and installation. But its advantage is that it is practically not subject to corrosion.

Its service life is determined by 50 years, while a steel heat exchanger can last only 15 years. Such a short duration of operation of a steel boiler is due to its low resistance to corrosive processes.

Corrosion in heating system occurs due to the presence of air in the coolant, as well as due to the formation of condensate, which, cooling down, settles on the walls of the steel heat exchanger. Therefore, most experts recommend installing gas boilers with a cast iron heat exchanger.

Single and double circuit boilers

The choice of a heating boiler depends on the desire of the homeowner to have only water heating or even hot water for domestic needs.

If the availability of hot water is not relevant, then you can purchase gas equipment with one circuit, which is much cheaper in cost. If it is required to provide people living in the house with hot water, then the choice will be for a double-circuit boiler.

Choice of burner, boiler power and ignition method

How to choose a burner

In Russia, gas pressure in pipelines is far from perfect, especially in winter time, and can drop to 13 mbar. As a result, the flame in the burner of the gas appliance may decrease, which leads to further burnout. Under such conditions, it is better to purchase a boiler with a fan burner, although art about it is more expensive and noisy during operation.

There are a lot of gas boilers of foreign manufacturers on the Russian market, which are designed for a stable nominal pressure in gas pipelines of 18-20 mbar. Therefore, acquiring imported equipment, you need to be prepared for the fact that in the winter cold, when the pressure in the main pipelines decreases, you risk being left without the desired heat.

Note! The decrease in pressure in the gas pipeline means that the boiler, which in terms of its power is capable of heating a room with an area of, for example, 250-300 sq. m, at low pressure will be able to heat only half of the declared area.

Piezo ignition or electric? Here you need to build on how much you want to save on gas consumption. Naturally, saving comes first. But in the event of a power outage, which is not uncommon in Russian conditions, you will be left without heating and hot water until electricity appears.

When ignited by a piezoelectric element, a small igniter is constantly lit in the boiler, which is waiting for the command to turn on the heating or hot water. And although it is small, some amount of gas is consumed during its combustion. With electric ignition, the boiler starts up automatically - you just need to turn the tap to the "hot water" position. And it also automatically turns off when the crane returns to its original position.

Boiler automation

Automation for gas boilers

For greater energy savings, there are special programs that are built into the design of the boiler and allow you to save gas with maximum efficiency.

For example, ionization control of combustion. This device can instantly shut off the gas supply to the burner in an extreme case. At the same time, in a boiler with electric ignition, the igniter does not burn at all, which allows you to save gas even more. It should be remembered that such devices are not allowed to be used in rooms with high humidity.

When choosing a volatile boiler, that is, one whose operation is directly related to the presence of electricity, you need to take care of purchasing a voltage stabilizer in electrical circuit or at least network filter. It is no secret that power surges in our electrical networks are not such a rare phenomenon.

However, you should not panic when the power goes out suddenly. Smart automation will block the operation of the gas boiler. And when the light appears, all functions will be restored automatically. And your heating system will keep the set temperature for several more hours. In addition, all the thermal resources of a heated house will keep pipes and radiators from freezing and bursting for 2-3 days.

There is an automatic technique that protects equipment from power surges. With a sharp increase in it, it simply turns off the boiler.

It is also possible to install an RCD ( differential machine), which protects not only equipment, but also a person from a short circuit if there is no grounding.

Important! Safety precautions when using electrically dependent equipment require a ground loop on gas boiler and connecting it to an individual automatic on-off device.

How to make heating calculations?

Heating scheme

Usually, all calculations for the proposed heating of the house are carried out at the design stage. At the same time, the choice of heating method is influenced by building parameters such as wall thickness, roof and roof construction, as well as the quality of thermal insulation work. And depending on these indicators, they select:

- boiler

- pipes and radiators

- highway slope

- type of wiring

- coolant flow diagram

- number of plumbing and household appliances

Approximately the power of gas equipment is calculated based on a simple rule - 1 kW of boiler power is spent on heating 10 square meters. meters of living space standard height ceilings. If the ceilings are higher than 3 meters, then this value can be increased to 20 square meters. m. Do not forget that approximately 25% of the power of gas equipment is spent on heating water in the hot water supply system.

Naturally, such calculations are very approximate. Therefore - if you want to do it as accurately as possible, then all calculations should be entrusted to specialists in this field.

Safety precautions when using gas equipment

Safety when using gas equipment

When deciding to install gas equipment, it is necessary to adhere to the requirements of SNiP 11-35-76 section "Boiler installations" and SP 41-104-2000, which spell out all the requirements for organizing the installation site and operation of these systems.

The most dangerous when using gas can be its leakage, which happens for a number of reasons:

- burner spontaneously extinguishes

- the pressure in the gas pipeline dropped sharply

- access to the chimney channel is blocked, as a result of which the draft has disappeared

- unauthorized power outage

- igniter went out, etc.

If at least one reason appears, gas access to the boiler should be immediately blocked. Modern gas appliances equipped with a whole arsenal of various automatic devices that are sensitive to the slightest changes in the operation of gas equipment.

These devices include:

- burner flame control sensor

- traction control sensor

- a device that blocks the operation of the boiler with a sharp decrease in gas pressure in main pipeline or turn it off completely.

- device that turns off the boiler in the absence of electricity

- sensor that monitors the level of coolant in the heating system

In addition to these monitoring and control devices, gas boilers must be provided with a security system, which includes:

- safety valve for the heating circuit and protection system that protects the heating unit from freezing

- automatic descaling system

- diagnostic system and others

Operation of gas equipment

Of course, installing so many complex devices is beyond the power of an ordinary consumer, but everyone must follow the safety rules. Therefore, it is worth choosing in which smart automation registers and diagnoses all kinds of non-standard situations in its work.

In addition to all the listed devices that make the operation of gas equipment safe, there are the latest developments - programmers. They allow the homeowner to control their equipment thanks to a digital display that reflects all boiler malfunctions.

Conclusion

Choosing a heating boiler for your home is not an easy task. Everyone wants to buy reliable and safe equipment that would provide both heat and hot water to the maximum. Yes, it would serve for many years without repairs.

But for this it is necessary to understand the principle of operation and design of these devices. Knowing this, you can accept correct solution in choosing a gas boiler.