Private house, country cottage or any other living space can be made comfortable and cozy. First of all, for this you need to carry out communications - heating and hot water. And now for this you do not need to buy expensive powerful units and equip an entire boiler room. A compact gas heating boiler, tied with a boiler, will cope with the task. indirect heating. The binding can be performed both at the time of installation of the boiler, and after, when the need arises.

Indirect heating boiler and its choice

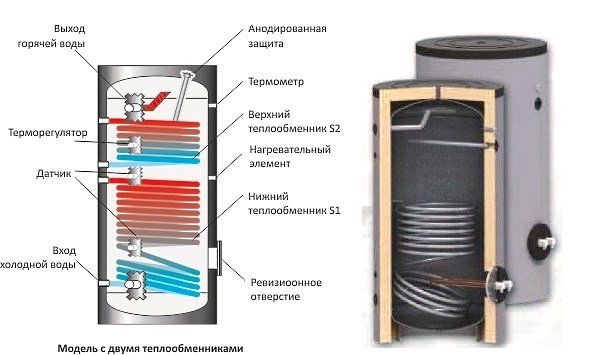

The boiler is a container for the coolant- water, with a heating element built into it. Water heating device It works on the principle of a storage tank: water is constantly in it, and its temperature is monitored using sensors. differs from direct heating boilers in the first place in that it cannot work autonomously. The boiler is not connected to electricity and has no burners or fireboxes. He needs a boiler to heat water. The choice of a heating boiler and an indirect heating boiler must be thought out to the smallest detail.

Must be combined and properly matched in power. If the boiler power is less power boiler, you will get a significant overrun of electricity, since it will take a lot of time to warm up the water. It is also important to take into account that the boiler will also work to maintain the temperature, which will also affect the wear of the boiler and electricity consumption. The best option when no more than 50 percent of the energy consumed by the boiler for heating is spent on water heating.

When choosing, it is important to check that the dimensions and types of connectors are suitable for the binding. Usually they make standard connectors, but if the manufacturers are different, you need to be extremely careful, otherwise the temperature sensor, which is connected in 2 ways to the boiler or to the module, may not work correctly or not connect at all.

It is better to choose a gas boiler with a boiler from one manufacturer, this will save you from many hidden problems, which can only be found out at the time of connection. If the work will be done by hand, it is important to be guided by the strapping scheme at each stage. One option is to consider a gas boiler with a built-in boiler: such units are slightly larger, but easier to install.

Also important to remember about auxiliary equipment, the most important is the circulation pump. The pump will “drive” the coolant through the heating system forcibly, so the temperature will be even and there will be less chance of occurrence in the pipes air locks. Electric pump also suitable for quick heating of rooms.

The designs of heating boilers allow you to choose two versions - floor and wall. In terms of power, they may not be inferior to each other, so the choice depends only on the preferences of the owner. Wall units look more compact, they do not take up usable space. According to the configuration, the wall-mounted boiler is a little “richer”, it already has a pump and an expansion tank. they can also have a flow or storage type of heating of the coolant.

Installation

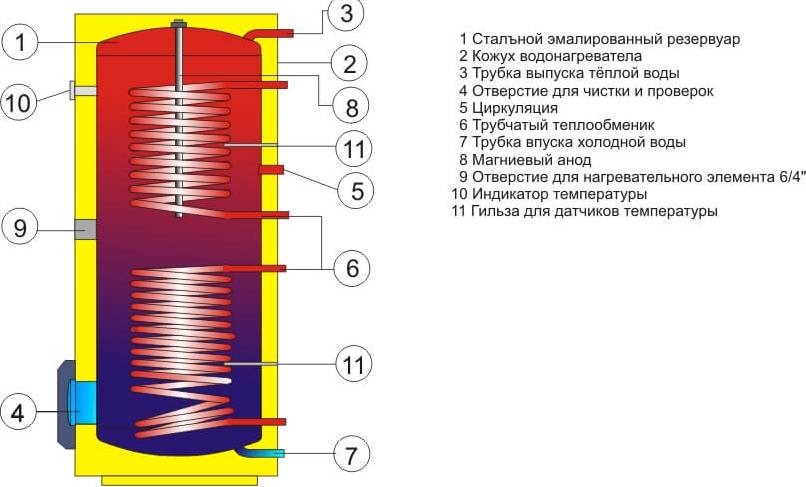

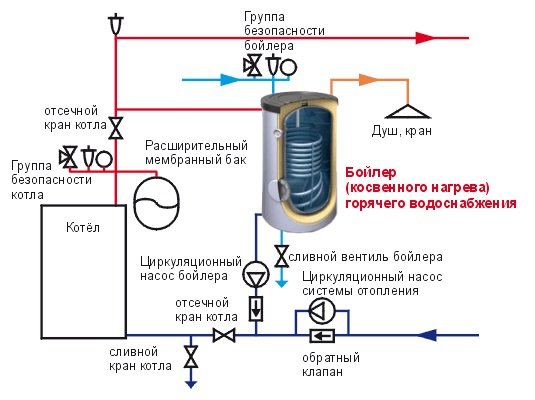

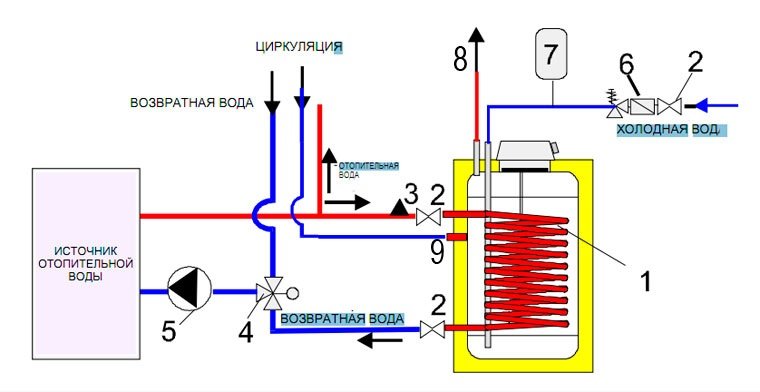

The indirect heating boiler device is simple, it consists of heating element in the form of a coil, protective electrode, insulation, and all this is included in metal case. For strapping, it is necessary, strictly following the diagram, to connect the boiler to the circulation pump. Connection sequence: output hot water, circulation circuit, circulation pump, check valve, discharge into the sewer, safety valve, valve, flow control valve, pressure gauge boss for non-return valve, draining the system, connection to the water mains, circuit expansion tank.

When connecting, it is important to remember:

- cold water connection must be from the bottom of the boiler;

- hot water is output from the top of the tank;

- the recirculation point must always be in the center of the boiler.

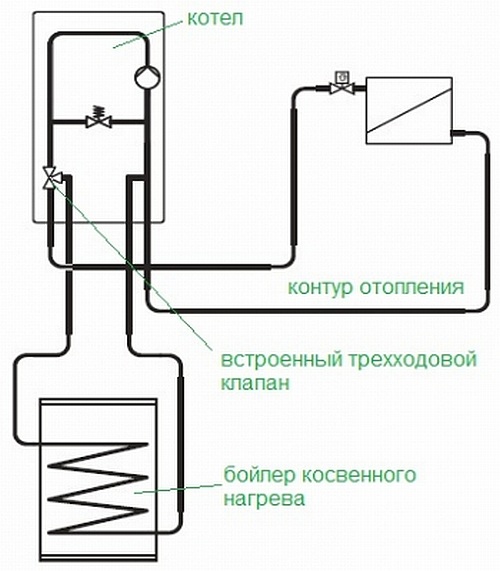

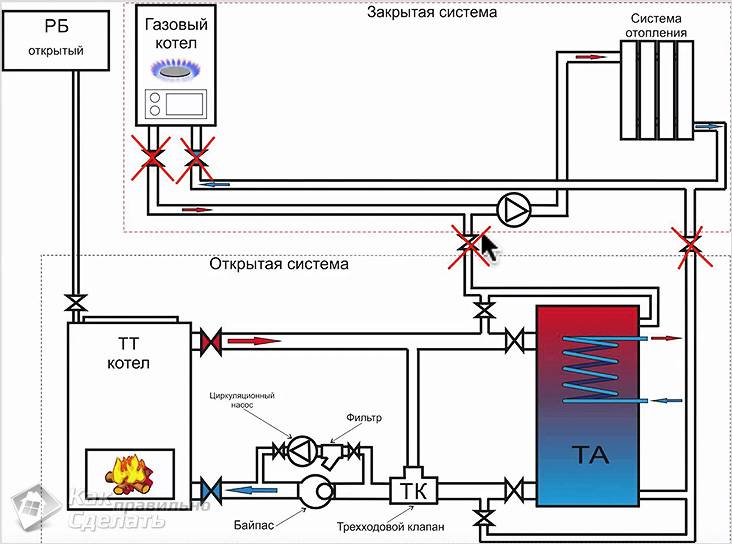

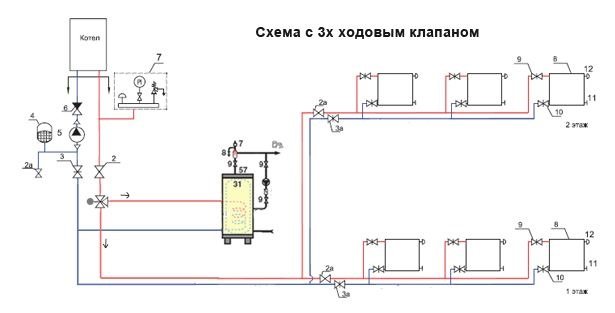

You can connect the boiler to the boiler using several schemes: use a three-way valve, a hydraulic arrow, or use two pumps at once.

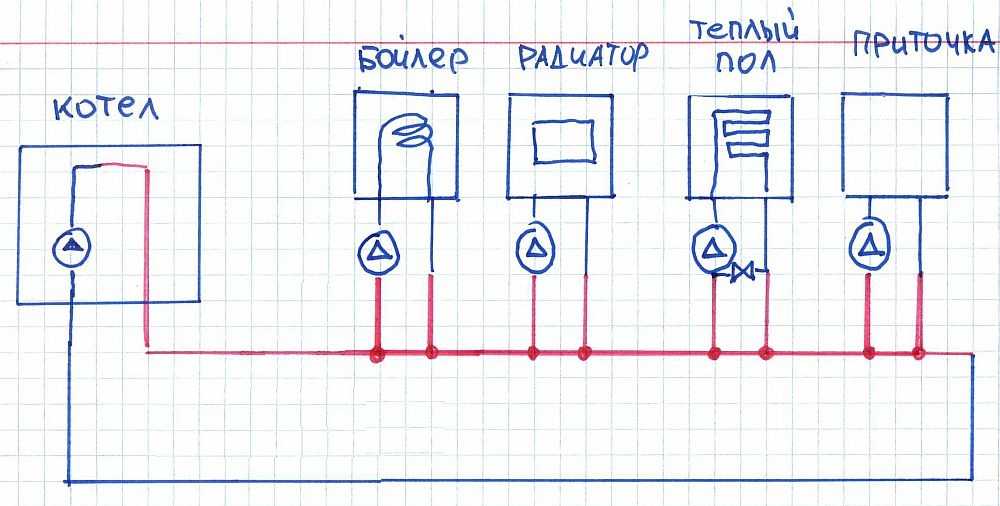

How to connect a boiler to a boiler using two pumps at once and is it profitable? All three connection schemes have a place to be, and the connection features are different for everyone. The scheme, in which two pumps are involved at once, differs only in that it is convenient when all circuits are located in parallel; the circuit also uses a check valve. The valve prevents mixing of coolant flows. Thus, it turns out that each circuit of the indirect heating boiler and boiler has its own pump, water circulation is faster and better. The pumps are controlled through a temperature sensor located on the storage device. It is important to remember that the heating circuit is not the main one!

At right choice and installation of a floor or wall-mounted heat generating unit, warmth and comfort must come to the house.

Not in all cases in the house it is immediately possible to connect the necessary communications. In most cases, hot water supply is carried out at the end of the repair or during the period when the cold season is approaching. As a rule, a boiler is often installed for this system. But as is known, at permanent job This device consumes a lot of electricity. And to make water heating more economical, we suggest you figure out how to connect it to the heating system. This will allow the water heater, during the heating period, to consume thermal energy heating and only in summer to heat water with heating elements. Let's compare different methods.

Connection to a double-circuit boiler

In order for heated water to enter the water heater from a two-circuit heating system, a three-way valve is mounted. It switches the flow of coolant from the batteries to the coil of the water supply circuit. With this scheme, it is important to ensure that a signal is applied to the three-way valve. It is also not necessary to install a recirculation pump on the coil. The main work is carried out by the heating system, which contains in its configuration this device. A recirculation pump is required only if the system is provided with a thermostat. As a result, when connecting a water heater to double-circuit system heating equipment can be selected based on needs.

To increase hydraulic circulation power heating system recirculation pump installed. Due to this, it is possible to control / adjust the thermal inertia, i.e. hydraulic friction heating.

There are boilers with a built-in boiler, both wall-mounted and floor-standing. Such equipment is more expensive, plus you can completely get rid of excess reinforcement. But on the other hand, floor-standing ones have built-in water heaters with a volume of up to 100 liters. This imposes obvious restrictions. Moreover, such samples cost around 60 thousand rubles. If we compare it with the price of a water heater, then there is a significant difference, which varies within 4.5 thousand rubles. Considering this, it is much more profitable to buy a device.

Let's compare several options for connecting an indirect heating water heater:

- Using a three-way valve.

- With the use of a hydraulic arrow.

- Return circulation method.

This method is based on 2 circuits: heating from the boiler and heating. A three-way valve will distribute warm water between them. To control the valve, automation (thermostat) is used. As soon as the water temperature in the heater circuit reaches a predetermined level, the automation sends a signal to the three-way valve. After that, warm water enters the batteries. This method is considered the most popular.

If you set the temperature limit, it is important to foresee to what extent the boiler heats up the water. Accordingly, the temperature in the water heater circuit must be set lower than in the connected device. Otherwise, the coolant will be constantly sent to the water heater.

![]()

The pumps will direct warm water to different circuits, i.e. the water heater is connected in parallel. Each line is equipped with a pump, the operation of which is controlled by a temperature sensor.

A check valve is introduced into the system after each pump. This will prevent conflict between two branches.

When the DHW is turned on, the heating stops working temporarily. Given the fact that the water is heated in the water heater in a short period of time, hot water in the radiators is not reached. critical temperature. If 2 boilers are used, then DHW heating and the operation of the heating will be uninterrupted.

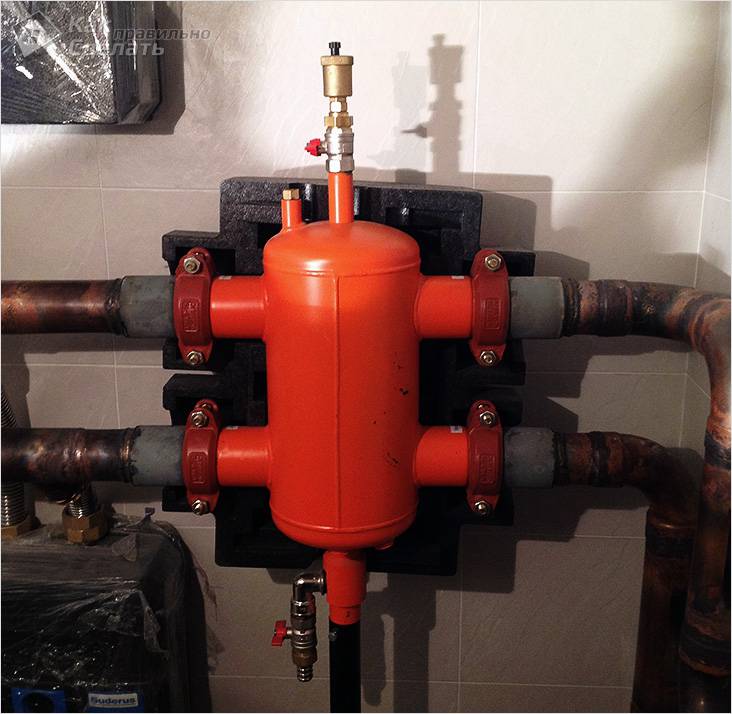

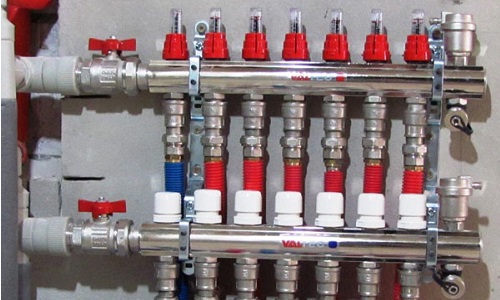

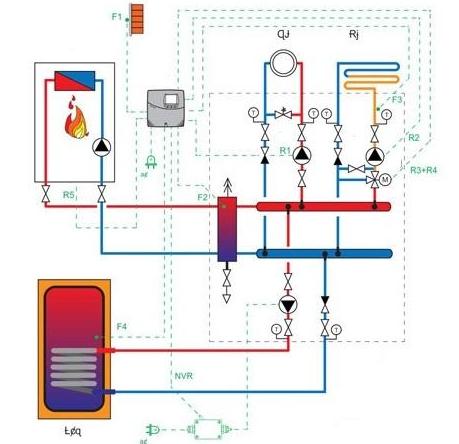

When using circulation pumps, it is important that the flows are equal. To do this, you can use a hydraulic arrow and hydraulic distributors. This is especially effective if it is necessary that the heated coolant is sent to floor heating, boiler and radiators. To level the pressure difference in the circuits, the parallel action of the hydraulic module with the hydrocollector. Although they can not be used by installing balancing cranes. But in this case, it will be difficult to install and adjust the system without the help of a specialist.

This connection technique is only possible if the boiler has a third inlet. It will be possible to connect the recirculation of the coolant to it. Thanks to this, the process of heating water can be made very fast. As a result, you will get rid of the problem of draining cold water from the tap until hot water comes out. This is a significant savings.

As a result, a looped main will be formed, through which water will constantly (forcedly) circulate. You will also need to connect the following items:

- Expansion tank. When the taps are closed, a stable pressure will be maintained in the hot pipeline.

- Safety valve. It will protect the water heater from pressure surges.

- Automatic air vent in front of the check valve. This will completely avoid airing the pump before starting it directly.

- Check valve. If there is high pressure in the system and, as a result, the water overheats, hot coolant will not enter the pipeline from cold water. It is installed at the inlet to the water heater.

The maximum pressure that is allowed in expansion tank not allowed above set pressure in the safety valve.

So, we examined the main options for connecting an indirect heating water heater. Let's highlight the pros and cons of this method:

Advantages:

- Several heaters can be used at the same time.

- Possibility of recycling.

- DHW and heating flows are separated.

- High performance.

- Significantly unloads electrical network during the heating period.

- The inner surface of the water heater does not come into contact with running water.

Flaws:

- More costs are required to re-equip the heating system.

- The first heating of water is carried out for more than one hour.

- Must have separate room where all equipment can be placed.

In this case, a scheme is used where 2 pumps are mounted. This will completely eliminate the use of a three-way valve. A similar system has already been described above, where the contours run in parallel. As soon as a signal is given from the thermostat, the pumps leading to the tank are turned on. It is also necessary to install a check valve that does not allow mixing of the coolant.

With this connection of the water heater, the return circulation method is also used. In this case, the coolant circulates continuously under the influence of the pump. Thanks to this, heated water flows faster to the faucet.

In this case, it is allowed to simultaneously have a system that will allow the coolant to be discharged in an emergency and the possibility of connecting hot water. Often thermostatic taps are mounted on batteries, but be aware of the risk of overheating. If a water heater is installed, then there is no such problem, because. surplus warm water will go to the tank. But remember that such a boiler connection is possible with natural circulation.

So, the following security group must be mounted:

- Shut-off valve.

- Drain tap.

- Shut-off valve and check valve.

- Water heater pump.

- Supply valve.

- Water heater safety group.

- Expansion tank.

When implementing installation work it is important to avoid any mistakes. This may lead to backfire. For example, it is important not only to take care of the proximity of the water heater to the boiler, but also to set the correct direction of the nozzles to the pipeline for easier installation. Another common mistake is the incorrect connection of the pressure pipe and the coolant inlet. Cold water is always supplied to the lower pipe, and hot to upper part water heater. There is also a risk of incorrect connection of the pump. It is important to comply with the parameters set out by the manufacturer.

Yes, we have reviewed possible methods connecting the water heater to the heating system. We hope this information will be useful to you and help you complete this task yourself. We also provide diagrams and videos to help.

Video

The principle of operation of an indirect heating boiler is shown in the video:

Make a connection gas boiler to the indirect heating boiler different ways. Water heater task accumulative type- heat up and keep in stock required amount water for hot water supply. The boiler must have time to provide thermal energy heating appliances and a heater, for which it must have a certain power reserve. The method of tying the boiler depends on the complexity and branching of the heating network at home. To choose it correctly, it is worth studying the drawings of several piping schemes for both units.

Parallel connection of units

The simplest parallel scheme for connecting an indirect heating boiler to a heat source operating on natural gas, is appropriate in such situations:

- boiler - wall type and is equipped with its own circulation pump;

- the heating system is simple, consisting of the same type of heating devices - radiators or underfloor heating;

- the water heater is small.

The parallel piping of the boiler is simple: the upper branch pipe of its heat exchanger is connected to the supply line of the gas boiler, and the lower branch pipe to the return line. As a result, the circulation of the heat carrier through the heating system and in the heat exchanger of the water heater occurs simultaneously and up to the same temperature. Its regulation is carried out on the boiler, which creates a lot of inconvenience:

It follows that a simple parallel connection of an indirect heating boiler to a heat generator is suitable for small house with few radiators.

Connection method with a separator node

To connect an indirect heating boiler with separation of coolant flows into heat supply and hot water, a three-way thermostatic valve. It is installed on the supply pipe from the boiler, and the branch to the water heater is connected to the valve outlet, which is initially open. The three-way valve is controlled by a remote temperature sensor. With this connection option, a gas boiler with a boiler works according to the following algorithm:

- At first, when the coolant is heating up, the circulation provided by the boiler pump occurs only in the water heater circuit. The three-way valve directs the entire flow to provide hot water.

- Upon reaching required temperature in the DHW circuit, a sensor is triggered and causes the three-way valve to direct the flow to the heating system, and close the outlet to the water heater.

- When the temperature in the tank drops either in DHW networks there is a water intake, then, at the signal of the sensor, the separating valve redirects the coolant again to heat the water in the boiler.

Although some of the shortcomings of the previous connection scheme are eliminated here, but this way still suitable only for simple systems with the same types of space heating. The alternating operation of the water heater and batteries allows them to operate more efficiently, the main thing is that the boiler has enough power. But, since the boiler is in priority over the radiators, at high flow rates in the DHW system, the heat generator may not have enough time to heat the water in the heating network. Therefore, when large numbers for people living in the house, such a scheme for connecting the boiler to the boiler can create inconvenience.

Connection with two pumps

An important advantage of this strapping method is the ability to function in the summer and provide the house with hot water when the heating is not working.

When the elements are mounted correctly, a three-way valve is not required, the flow is redirected by turning on the circulation pumps one by one.

Each of them is controlled by an overhead thermostat that records the temperature of the water in the water heater tank. If it is insufficient, then the pump of the water heating circuit works, the coolant works for the needs of hot water supply, and the circulation in the heating network is suspended. When set temperature reached, the thermostat switches off the pump DHW circuit, after which it starts pump unit heating systems.

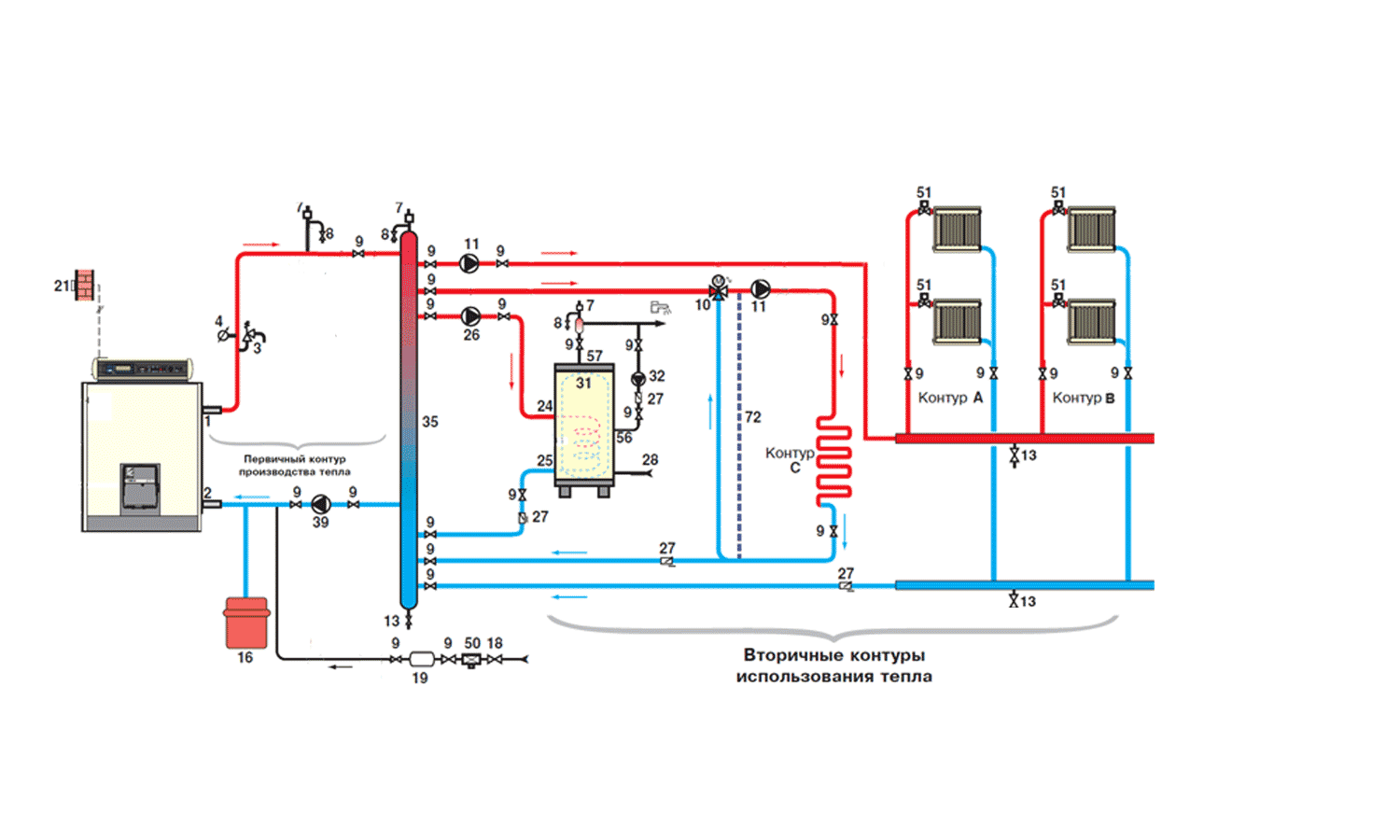

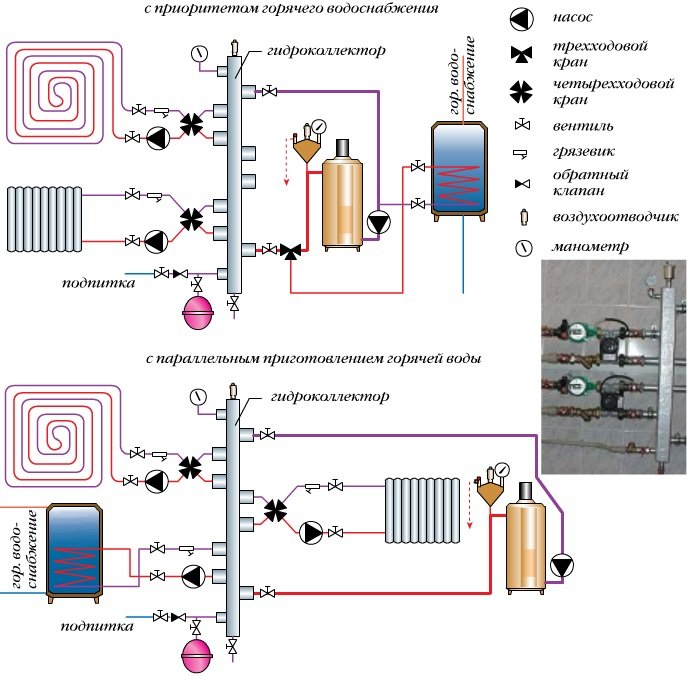

When the area of the cottage is large and it is heated various systems- radiators, warm floors and skirting boards, then parallel connection of a single-circuit gas boiler and a storage water heater will not work. An extensive network with several circulation pumps providing separate heating branches requires the installation of a hydraulic separator with a distribution manifold. An indirect heating boiler is attached to it, moreover, with its own pumping unit.

With this option, it is also customary to connect the pump for the boiler through a thermostat in order to save energy and not take the coolant away from other heating circuits. Such a scheme has the following advantages:

- a single-circuit boiler correctly selected in terms of power will provide the necessary amount of heat to all heating branches, including an indirect heating boiler;

- each branch is isolated and hydraulically separated from the heat generator, therefore heating network does not affect the operation of the water heater and vice versa;

- the circuit will always work stably, even with a large drawdown in the DHW network, organized with hot water recirculation.

These advantages arise due to the use of expensive equipment in the strapping. Hence the disadvantages of the circuit - the high cost and complexity of installation, but country cottage large area and inexpensive heating are incompatible concepts.

How not to tie equipment?

There is a widespread belief that connecting a boiler to double-circuit boiler can be performed by docking the DHW circuit of the heat generator with an indirect water heater. There are 2 options for the development of events:

- The family uses a double-circuit gas heater, but the owner is not satisfied with its performance. Then he buys an indirect heating boiler and connects it to the secondary circuit of the boiler, using an additional circulation pump.

- The initially misled homeowner acquires a funded hot water unit together with a double-circuit heat generator and tie them as described above.

This method of docking the units is erroneous and will not lead to an increase in the hot water capacity of the system. The reason is the limited capacity of the secondary heat exchanger of the boiler, designed to produce 7-12 liters per minute of water heated to 30-35°C. While the capacity of the water heater tank is from 100 liters, and this volume of water needs to be heated to 50-55 ° C.

During the time that the boiler is heating up, the heating system will remain without heat and the building will begin to cool down. When the boiler finally switches to heating, it will have to work at maximum long time to restore the microclimate in the house. Therefore, the scheme for connecting a double-circuit heat generator to an indirect heating unit is no different from piping with a single-circuit boiler.

Moreover, you do not need to buy a dual-circuit heat source to work with a boiler. A single-circuit gas boiler is appropriate here suitable type. The best option recommended by experts - both units are made by the same manufacturer.

To provide the house with the necessary amount of hot water, they use additional device- indirect heating boiler (BKN). Its use can be considered one of the most rational and economically justified. We will try to find out which indirect heating boiler piping scheme is the most effective and how to connect the equipment in order to avoid common mistakes.

Before buying and connecting a buffer tank-accumulator (as BKN is also called), you should understand the design features of the most popular types. The fact is that there are many types of equipment, including combined models that work from heating systems and alternative sources energy at the same time.

We will consider traditional boilers with a coil, using hot water as a heater.

Design features and principle of operation

What does indirect heating mean? Directly heated devices operate by connecting to electricity or gas burner, BKN has a different heat source. Water is heated by connecting to a hot water supply, that is, it turns out that the source is the coolant - hot water (or its substitute).

Outwardly, the BKN resembles a standard water heater - that is, it has a barrel shape, although modern models more ergonomic. For ease of use and installation, they are given a rectangular configuration.

Considering new models famous brands, then it can be seen that gas boilers and KH boilers often have the same design. They are mounted next to each other or one below the other - this way you can save on space.

The main element that performs the heating function is a steel or brass heat exchanger (coil) with a large surface area, which is located inside a metal coated protective layer tank enamel. To prevent the water from cooling too quickly, outside the body is surrounded by a layer of thermal insulation, and some models are surrounded by a casing.

If you want the water in the boiler to heat up quickly, choose a model with several heat exchangers, and to cool slowly - with high-quality thermal insulation

An important detail, which is now equipped with most heating appliances, is a magnesium anode. A rod attached to the top of the device protects metal parts from the formation of corrosion, as a result, the water heater lasts much longer.

Barriers from action high pressure are safety valve and built-in thermostat. If the tank is not equipped with a safety group, it is installed separately when arranging the piping.

Often the water circulating in the heating system does not exceed 65-70ºС. Many doubt its effectiveness when it acts as a heat source for heating in the BKN. In fact, the specified temperature is sufficient, because the rate and magnitude of heat transfer depends largely on the area (rather large) in contact with the water coil.

How does the heating process take place? Cold water, intended for heating, enters through a separate hole and fills the entire container. Water also enters the heat exchanger from the boiler, but already heated. The hot walls of the coil transfer heat to cold water, which at the outlet is already at a temperature suitable for taking a shower or washing dishes.

Why is a controlled boiler better?

The ability to control is a characteristic that affects the assembly of the entire water heating system. There are two types of BKN: simple (cheaper) and with built-in control function.

Control of the heating process is mandatory if the main heating device - for example, a gas or solid fuel boiler - does not have a control unit

A distinctive feature of controlled models is the additional equipment with a temperature sensor and the ability to supply / stop the supply of water to the heat exchanger. Such equipment works automatically. To start you need to connect:

- inlet/outlet for hot water from DHW;

- supply of cold water to the tank;

- collector for distributing the heated liquid at the outlet.

After that, you can start the boiler - the water will begin to heat up.

If the boiler is operating in automatic mode, there is no need to control the boiler. But it is still better to equip it with a temperature sensor (there is a place in the case for this)

The process of connecting and tying an indirect heating boiler occurs in one of the ways (description - below).

How can control affect water temperature? Almost nothing. The maximum value that the outlet temperature can reach does not exceed the parameters of the heat carrier in the DHW system. Most likely, it will be lower by 1-2ºС. If more intense heating is needed (this can happen if the boiler usually operates in low temperature mode), then it is better to choose a model with a built-in heating element.

It is advisable to buy such equipment together with solid fuel boilers (the water remains hot even after the boiler has cooled down).

Varieties of devices with additional functions

Tanks with a simple design are only part of the range on the market water heating equipment. There are sophisticated models whose functions are very useful for integration into DHW system.

For example, one of the purposes of more expensive models is heat accumulation. If power outages are possible or daily consumer tariffs are too high, the accumulation mode will be very useful. Design features such models - reinforced thermal insulation and increased tank volume (300 liters or more).

Another option that implements the fastest supply of hot water to the taps is a recirculation boiler. Unlike conventional design, this one is equipped with three pipes for communication with the hot water supply system. Hot water is supplied by two, cold water is supplied by one. Water is supplied by a pump.

When using a model with recirculation, you can equip an additional useful circuit, for example, for mounting a heated towel rail.

Less common than devices with coils are tank-in-tank models. The container with the water to be heated is inside, the heating circuit is outside

Water in such a tank heats up faster than in units with a heat exchanger, but its cost is higher.

Does tank size matter?

Cylindrical and cubic tanks differ in their size. Their volume is indicated in liters: there are small models for 80-100 liters, but there are also bulky ones that can hold up to 1400-1500 liters. The size is selected based on the family's need for hot water.

Dimensions are important during installation. For wall mounting only light models are suitable - up to 200 l, all the rest are floor-mounted. Both horizontal and vertical wall-mounted devices in the kit have special mounts, floor devices are equipped with legs or a small stand.

The branch pipes necessary for connecting water and coolant are usually brought out from behind and from above, so that it is more convenient to attach the tank to the pipes. The front panel of a number of models is equipped with a temperature sensor (relay) and a technical hole

Rectangular units occupy a little less space than cylindrical, due to the tight fit to the pipes.

The nuances of the strapping device

It is easier to do wiring and piping if the KN boiler is installed together with the boiler, pumps and other equipment involved in the assembly of the DHW system. Embedding an additional device into an already existing network is much more difficult. In any case, for normal operation devices will have to follow a number of rules:

- choose the right place for installation - as close as possible to the boiler;

- provide flat surface for boiler installation;

- to protect against thermal expansion, install a membrane accumulator (at the outlet of heated water), the volume of which is at least 1/10 of the volume of the BKN;

- equip each circuit with a ball valve - for convenient and safe maintenance of devices (for example, a three-way valve, a pump or the boiler itself);

- to protect against backflow, install check valves on the water supply pipes;

- improve water quality by inserting filters;

- correctly position the pump (or several pumps) - the motor axis must be in a horizontal position.

For safety reasons, do not attempt to mount heavy devices on drywall or thin wooden partitions. Concrete and brick walls are suitable. Brackets or other types of holders are fixed with brackets, anchors, dowels.

Regardless of the type of device - floor or wall - if possible, it is mounted above the level at which the boiler is installed, or at the same level. For outdoor, you can make a pedestal or a solid stand up to 1 m high

When installing, the nozzles are directed towards the boiler (even if they are masked in the back or behind a false wall). Do not use unreliable equipment, such as corrugated hoses that cannot withstand the pressure and pressure of water.

What is priority heating

Before installing an indirect heating boiler in the DHW system, you must select the principle of its connection: with or without priority. In the first case, when there is a need for a quick receipt a large number hot water, the entire volume of the coolant is pumped through the BKN coil, as a result of which the water heats up much faster.

After the water temperature has reached required mark(measured by a thermostat), there is a way to redirect the flow to radiators.

Connection without priority does not allow the passage of the entire volume of the coolant, and the boiler serves only a part of the total flow. With the equipment of such a scheme, the water heats up longer.

BKN connection diagram without priority: a separate circuit is connected to the boiler, so there is no possibility to cut off radiators (or other heating devices)

The priority scheme is more efficient, as it makes it possible to quickly heat the required amount of water without compromising heating. If the heaters are turned off for 30-50 minutes, the temperature in the rooms is unlikely to drop in such a short period of time, but there will be enough heated water. The only condition for the equipment of the priority scheme is a powerful boiler.

Schemes and rules for connecting BKN

The connection diagram and installation features of an indirect heating boiler depend on the class of the device and the heating system in the house. It is necessary to choose the right installation site, focusing on the location of the boiler, the tie-in of the pumps and the existing wiring. Let's try to figure out what needs to be considered when installing heating equipment.

Piping scheme with a three-way valve

This is one of the most popular schemes, since when it is used, the heating system and the BKN are connected in parallel, equipped with shutoff valves. The boiler must be installed near the boiler, the circulation pump should be connected to the supply, then the three-way valve. This scheme successfully applied if several heating appliances eg two different boilers.

A three-way valve is a kind of switch that is controlled by a thermal relay. When the temperature drops, the automation is activated, and the coolant flow from the heating circuit is redirected to the BKN

Essentially, it is a priority system that provides fast heating water in the boiler when the radiators are completely turned off for a while. As soon as the temperature rises to the set value, the three-way valve is activated again and the coolant returns to the previous channel - to the heating system. This strapping method is useful for those who use the boiler in constant mode.

Connection with two circulation pumps

If the boiler is rarely used (for example, seasonally or on weekends) or there is a need for water whose temperature is lower than in the heating system, a scheme with two circulation pumps is used. The first is installed on the supply pipe, immediately before the BKN, the second - on the heating circuit.

The circulation pump is powered by a thermal relay, so it starts to operate only when the temperature drops below the required one. The acceleration of heating occurs together with the inclusion of forced circulation

There is no three-way valve in this scheme; the piping is equipped with simple connecting tees.

Harness with hydraulic switch

This connection is used for volumetric boilers (200 liters or more) and branched heating systems with many additional circuits. An example is the heating system in two-story house where, in addition to a multi-circuit radiator network, underfloor heating is used.

A hydraulic distributor (hydraulic arrow) is needed to simplify the heating system layout and avoid installing recirculation pumps on each heating branch

The equipment of the hydraulic arrow avoids thermal shock, since the water pressure in each circuit will be the same. It is rather difficult to make a strapping according to this scheme on your own, so it is better to turn to professional installers.

How to use coolant recirculation

Recirculation is useful when there is a circuit that needs a constant supply of hot water - for example, a heated towel rail. If it is connected to the heating system, the coolant will constantly circulate, and the dryer will function and at the same time serve as a heating device.

The use of recycling has one great advantage- no need to wait for the water to heat up to desired temperature she will always be hot

But this scheme also has disadvantages. The main one is an increase in fuel costs, because constant heating of the water cooled in the circuit is required. The second disadvantage is the mixing of water in the boiler. Usually hot water is in the upper part, and from there it goes to the points of draw-off, here it is mixed with cold water, as a result of which the outlet temperature is slightly lower.

There are models of boilers with built-in recirculation, that is, with ready-made pipes for connecting a heated towel rail. But it’s cheaper to buy a regular tank by using tees to connect.

Scheme for working with a non-volatile boiler

A distinctive feature of this scheme is the installation of a boiler for more high level than a boiler and heating appliances. Preference is given to wall models that can be hung at a height of 1 m above the floor.

Floor models specifically within this scheme are inferior to wall speed and heating quality. The water temperature is much lower (approximately as in the return pipeline), therefore, the supply of hot water is less

A non-volatile type of heating is based on the application of the laws of gravity, therefore, the coolant will circulate even when the electricity is turned off. In normal mode, you can connect circulation pumps.

Connection course for indirect heating boiler

After choosing a scheme, it becomes clear what equipment is required. In addition to the main appliances, you may need valves, Ball Valves, distribution manifolds, valves (three-way or non-return).

Procedure:

- prepare the installation site (on the floor or on the wall);

- make the wiring, marking the outlets of hot / cold water in red / blue;

- embed a tee and a pressure relief valve, securing the connections with sealant;

- screw on hot (top) and cold (bottom) water taps;

- connection to a power source, install a thermostat and automation;

- select heating mode;

- test the connection.

Video instruction for connecting BKN

How to decide on the connection diagram and install the equipment correctly, the following videos will tell you.

General information about connection diagrams:

Practical tips for installation:

BKN strapping overview:

Professional review of the 80 l boiler:

In addition to installing and connecting the BKN, regular maintenance will be required. It consists in flushing the internal cavity of the tank, removing deposits and scale, replacing the magnesium anode. Maintenance of equipment does not require much effort. If the strapping is done correctly, quick repairs will not be required, but if problems arise with the equipment, we recommend contacting specialists.

To heat water in an indirect heating boiler, you can use a gas or solid fuel boiler, solar water heater or a heat pump. It is possible to work instantaneous water heater of this type, both in conjunction with a single-circuit and a double-circuit heating unit. WITH indirect heating boiler connection diagram varies depending on the type of boiler and the selected method of hot water supply.

Features of connecting the boiler

The piping of the water heater requires its connection to the heating system, as well as to the cold and hot water supply lines. Wherein cold water comes from below, hot water is removed from the top of the tank, and the recirculation point is located approximately in the middle of the boiler.

The heated coolant should move in the opposite direction - from top to bottom.

The heat carrier from the boiler enters the upper pipe of the water heater, and returns to heating main from the bottom of the boiler.

Thus, the efficiency of the device is increased by transferring heat first to the hottest layers of water.

For correct connection boiler, you need to know the basic ways to connect it.

Connecting a wall-mounted boiler to heating unit

Connecting the boiler to a gas boiler

To connect an indirect heating boiler to a gas heating boiler, its design provides for a temperature sensor installed in the tank.

Connection to a double-circuit boiler

To operate the boiler in tandem with a heating unit that has a hot water circuit, a three-way valve is used. With its help, the heated coolant flow is distributed between the main heating circuit and the additional hot water circuit.

The three-way valve is controlled by signals that come from a thermostat installed in the water heater. When the water in the boiler cools below the set value, the thermostat turns on a valve that directs the flow of coolant from the heating pipeline to the hot water circuit. The thermostat switches the valve to its original state when the temperature of the water in the tank reaches above the set value. In this case, the coolant flow is directed to the heating main. In the warm season, the flow is not redirected, but the combustion mode of the boiler is controlled. When the water temperature in the boiler drops, the thermostat “ignites” the main burner of the unit through a three-way valve, and when it rises, the gas supply to the burner stops.

Connecting the boiler to the boiler using a three-way valve

This connection diagram is perfect for gas boilers equipped with a circulation pump and automation. In this case, the valve can be controlled by the boiler itself by a command received from the water heater thermostat.

In a connection scheme with a three-way valve, the water heater circuit has priority over the heating circuit. The use of this method of connecting the boiler is justified for tanks of large volume or with high water hardness, which will prevent the DHW circuit from working normally.

Installing maximum temperature water in the boiler (temperature of the thermostat operation), it should be borne in mind that it must be less than the temperature set for the boiler automation.

Connection to a single-circuit heating unit

When connecting a water heater to a single-circuit boiler, a scheme with two circulation pumps is used. This type of connection can actually replace the three-way sensor circuit. A feature of this connection is the separation of coolant flows through different pipelines using pumps. The hot water circuit also has a higher priority than the heating circuit, but this is achieved only by setting the switching algorithm. Therefore, it is more correct to speak of the parallel operation of both circuits.

Alternate switching centrifugal pumps also carried out according to the signals of the thermostat installed in the tank.

To prevent mixing of coolant flows, a check valve must be installed before each pump.

Boiler installation diagram in a system with two circulation pumps

The operation according to this scheme is similar to the previous case, with the only difference being that the thermostat controls the alternating operation of two pumps. When the DHW pump is turned on, the heating pump is turned off, therefore, the heating system starts to cool down. but a short time heating water in the boiler does not lead to a noticeable decrease in the house temperature and can only be felt during the initial start-up.

Sometimes several heating units are used to heat houses of a large area. In this case, an additional pump is installed to ensure the operation of the water heater.

Scheme using a hydrocollector

The use of a hydrocollector in heating systems with several circuits

In complex multi-circuit heating systems, there are several circulation pumps responsible for ensuring the operation of individual circuits. In order to balance the coolant flows from different pumps, a hydraulic distributor or manifold is used. This device allows you to compensate for pressure drops in various circuits and branches of the heating system. Without a hydrocollector, balancing valves would have to be used, which greatly complicates the setup and operation of the heating system and the arrangement of hot water supply.

When using an indirect heating boiler in such a system, additionally consult with practitioners.

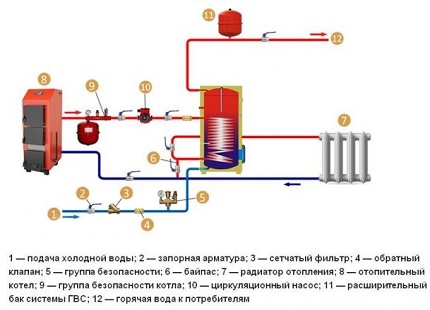

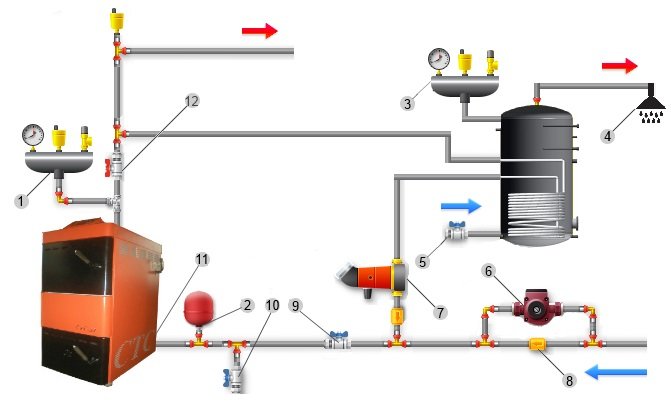

Connection storage water heater to a solid fuel boiler they achieve two goals at once - they connect hot water supply and get a system for emergency discharge of the coolant. The point is that in systems with solid fuel boilers often, in order to increase comfort, thermostatic valves are installed on radiators. However, in this case, the boiler may overheat. The same threat is real in case of unstable power supply for systems with forced circulation coolant.

In the case of installing a high-capacity boiler, this process is not terrible, since the excess heat is used to heat the water in the water heater tank. Of course, for the operation of such a system, it is necessary to install a boiler with natural circulation.

Scheme of connecting an indirect heating boiler to a solid fuel boiler

Solid fuel boiler safety group.

- The tank is expansion.

- Boiler safety group.

- Hot water pipeline.

- Shut-off valve on the supply line.

- Heating system pump.

- Water heater pump.

- Check Valve.

- Shut-off valve.

- Drain valve.

- The boiler is solid fuel.

- Boiler cut-off valve.

To close a branch natural circulation when the pump is running, a check valve is installed on the outlet pipe of the water heater. When the pump is turned off, the valve opens, allowing heat to be discharged into the boiler.

Check valve is important element systems

The boiler, which has an inlet of the recirculation line, allows instantaneous supply of hot water. At the same time, by opening the tap, it is not necessary to drain cold water from the “hot” pipeline.

This is possible due to the use of a separate loop circuit with its own circulation pump. Such a circuit is called a recirculation system. A heated towel rail can be additionally installed in this line.

Scheme of a boiler included in the recirculation system

In the piping of the boiler included in the recirculation system, the following are used:

- Non-return valve - to prevent mixing of hot and cold water flow.

- Air outlet - to prevent air from entering the system when the pump is turned on.

- Safety valve - serves for emergency pressure relief.

- Expansion tank - compensates thermal expansion coolant with closed taps.

The pressure in the expansion tank must not exceed the opening pressure of the safety valve.

Errors during installation

When performing installation or during operation of the boiler, it is necessary to avoid typical mistakes:

- Installing a boiler at a considerable distance from the boiler. It is necessary not only to install the water heater as close as possible to the heating unit, but also to correctly orient its nozzles relative to the pipelines to facilitate installation.

- Incorrect connection of the coolant inlet and pressure pipe. The coolant is always supplied to the upper part of the boiler, and cold water to the lower pipe.

- Wrong installation circulation pump. The pump should be oriented according to the manufacturer's instructions.

Installation, performed in accordance with all the rules, will not only provide reliable hot water supply at any time of the year, but will also enable the boiler to operate in a more gentle, economical mode.

Video. Connecting an indirect heating boiler to a gas boiler