The most optimal heating for a private house is gas. It is economical and affordable way, which features reliability and environmental friendliness, high efficiency and easy-to-use equipment. However, it is not always possible to supply gas to the site. Then you have to use alternative options, one of which is equipment for solid fuels (wood, pallets, coal, etc.).

Using solid fuel boilers is the cheapest and most economical heating method country house... This method is environmentally friendly, since firewood and other natural fuels do not emit hazardous substances when burned. The equipment does not depend on electricity and works autonomously for a long time, especially structures long burning... The boilers are characterized by reliability and long service life. They rarely require replacement parts or repairs.

but solid fuel boilers require preparation and manual filling of fuel, which is significant disadvantage... The disadvantages include the complexity of the installation, since solid fuel boilers require a separate boiler room, a special substrate, installation of ventilation and a chimney.

Today the market offers different models solid fuel equipment, which differ in power and size, price and quality, burning time and type of fuel. In this article, we will look at how to choose a reliable long-burning wood-burning boiler for heating a private house.

How to choose a boiler for long burning on wood

Long burning wood burning boilers - modern powerful and reliable equipment, which is characterized by high performance and good heat transfer. You will easily find automated models with smooth adjustment and easy maintenance.

Long-burning boilers are distinguished by a long-term autonomous combustion resource without the need to change the fuel. Such a resource is from 12 hours to 5 days! In addition, he is not picky about the quality of firewood. Such equipment will work for 10-15 years.

Before buying, determine required power... To heat 10 square meters an insulated house will require 1 kW of power. Thus, to heat a house with an area of 150 square meters, a 15 kW boiler is needed. There are two-circuit and single-circuit models. The first option gives both heat and hot water, the second only heats the room.

Solid fuel boilers also differ in the type of material of manufacture. Cast iron and steel models... Steel equipment is a monoblock, which is distinguished by endurance to temperature extremes and modern automation. Steel boilers heat up faster and cool down faster if necessary.

However, such equipment is difficult and sometimes impossible to repair. Cast iron boilers consist of sections that are easy to replace and repair. They are less susceptible to corrosion, but not resistant to temperature changes.

The best boilers for long burning on wood

| Model | Description | Advantages | disadvantages | Price |

| Buderus Logano G221 (Germany) | Single-circuit boiler with an efficiency of 78% and a power of 20 kW, for an area of up to 200 sq. m | Holds firewood up to 68 cm long, works with coal and coke; easy installation and cleaning, large chamber | Heavy weight | 65,500 - 102,000 rubles |

| Lamborghini WBL 7 (Italy) | Combined single-circuit boiler made of cast iron with a power of 29.4 kW and an efficiency of up to 90%, suitable for a house of 280 sq. m | Switching from solid fuel to gas; wide door for loading firewood; high efficiency | May break if overheated | 87,000 - 116,000 rubles |

| Stropuva S (Lithuania) | Single-circuit model with an efficiency of 85-91% and a power of 20 kW for a house of 200 sq. m | High efficiency; easy management and maintenance; compact size | Small windows for loading fuel | 92,000 - 100,000 rubles |

| Aremikas Candle S (Lithuania) | Single-circuit boiler in the form of a cylinder with a capacity of 18-20 kW and an efficiency of 86-93%, for an area of up to 200 sq. m | Economical fuel consumption; narrow, compact and sleek; | Complex system setup | 82,000 - 150,000 rubles |

| Viadrus Hercules U22D (Czech Republic) | Single-circuit cast iron combined equipment with an efficiency of 80% and a power of 23.3 kW for a house of 200 sq. m | A burner can be installed; works on coal, wood, briquettes, gas and pellets; efficiency and noiselessness | Small depth of the firebox; non-standard components (chimney and pipes) complicate installation and repair | 60,500 - 110,000 rubles |

| Wirbel Eko 17 (Austria) | Combined single-circuit design for heating a house up to 100 sq. m with a power of 20 kW and an efficiency of 71% | Can be switched to gas, economy and environmental friendliness, reliability | Requires 320 W mains connection | 51,000 - 66,000 rubles |

| ZOTA Master 20 (Russia) | Single-circuit model with a power of 20 kW and an efficiency of 71%, for an area of up to 100 sq. m | Powered by wood and coal, affordable and compact, easy maintenance | Modest basic equipment | 24,000 - 35,000 rubles |

How to install a solid fuel boiler

Solid fuel boilers, unlike gas boilers, can be installed independently. But such equipment requires placement in a separate boiler room. All solid fuel boilers are floor standing, so even compact models will require a lot of space. In addition, the boiler must not be installed directly on a wooden floor. The heavy weight of the structure doubles after heating! Therefore, a special foundation is made for the equipment.

The area of the boiler room must be at least 7 square meters with equipped ventilation. Interesting projects wooden houses from a log you will find at the link http://marisrub.ru/proekts/proekty-domov-s-kotelnoj /. Didn't like any of the options? Experienced architects and engineers of "MariSrub" will create individual project taking into account your wishes!

The distance from the boiler to the walls is at least 50 centimeters, to flammable objects - at least 25, and to fuel (wood, coal, etc.) - at least 40. Non-combustible is used as a foundation for the structure. Construction Materials... After the boiler is installed, a chimney is installed. Subsequently, you need to regularly inspect and clean the equipment.

Installing solid fuel boilers is a laborious and complex process that requires knowledge and strength. The durability, safety and efficiency of heating depend on the quality of equipment and installation. To avoid mistakes and get a reliable result, contact the professionals! Masters of "MariSrub" will select suitable system heating for your home and will choose reliable equipment, quickly and efficiently carry out the installation of the boiler room and the installation of any type of boilers!

With a limited choice of energy sources, wood-fired heating may not have an alternative at all. It is important to purchase a suitable wood-burning boiler and understand the specifics of its operation. We will tell you about these heating units starting with the choice suitable variety and ending with installation questions.

The main types of wood-burning boilers

The arsenal of heating equipment is constantly replenished with new, more advanced products, however, nothing radically new has been invented among solid fuel boilers. In attempts to increase efficiency, the designers somehow improved the design, which is why several varieties appeared with a number of characteristic features:

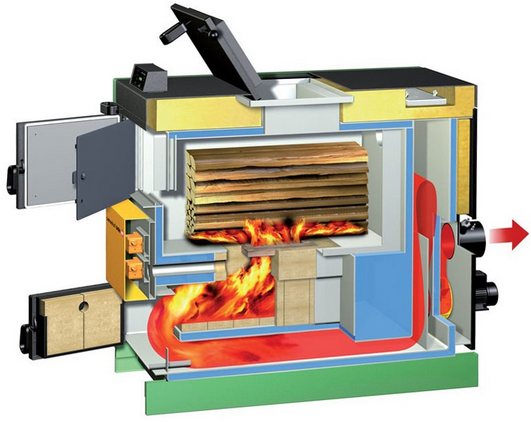

1. Complex Z-shape of the furnace or its division into 2 combustion chambers. Such boilers are designed for long-term combustion and the most complete combustion of the emitted pyrolysis gases.

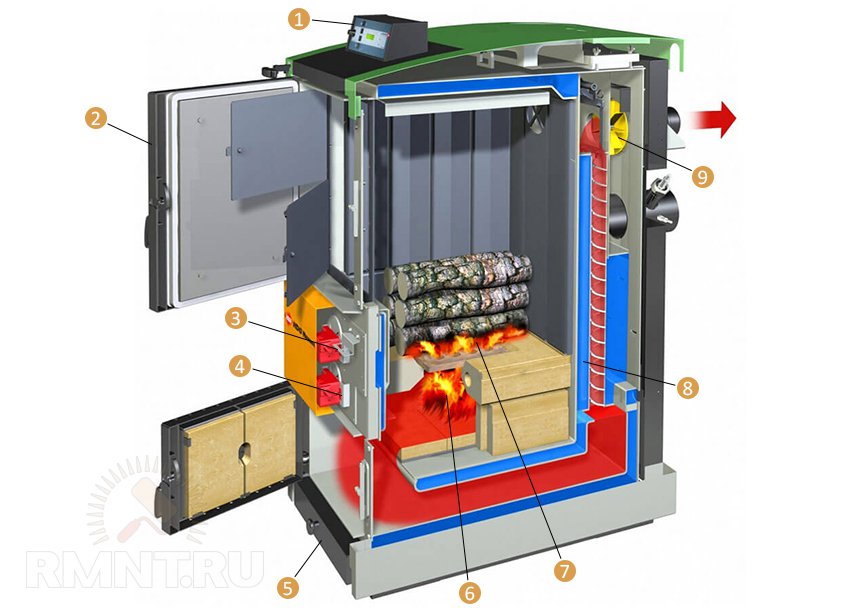

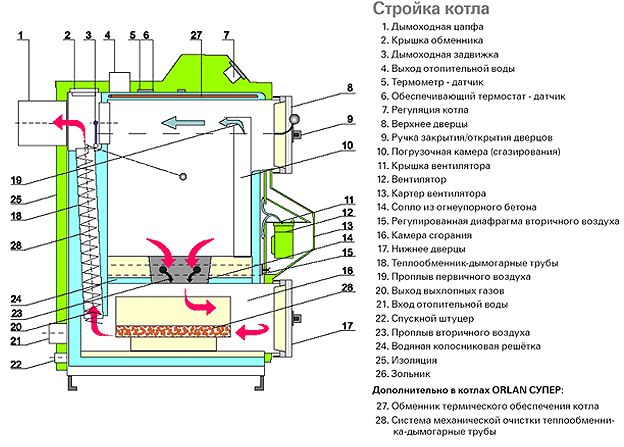

An example of the design of a long-burning solid fuel boiler: 1 - boiler automation; 2 - loading door; 3 - primary air supply; 4 - secondary air supply; 5 - ash pan; 6 - combustion of pyrolysis gases; 7 - pyrolysis solid fuel; 8 - heat exchanger; 9 - fan-exhauster

An example of the design of a long-burning solid fuel boiler: 1 - boiler automation; 2 - loading door; 3 - primary air supply; 4 - secondary air supply; 5 - ash pan; 6 - combustion of pyrolysis gases; 7 - pyrolysis solid fuel; 8 - heat exchanger; 9 - fan-exhauster

2. The presence of water-filled grates and / or a jacket. It is believed that in this way the coolant takes up to 90% of the heat of combustion, but in practice, good wood-fired boilers with an efficiency higher than 80% is already a rarity.

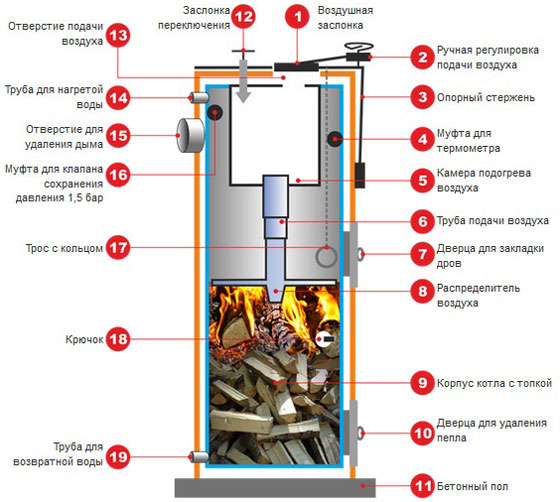

3. Form of organization of blowing. By reducing the oxygen supplied, the duration of combustion can be greatly extended, maintaining the temperature of the water within the specified limits. It is usually realized by means of a manual or controlled damper; if the draft is not strong enough, a blower fan can be used. The damper is usually controlled by digital automation, which controls the temperature of the water in the supply pipe.

4. Type and device of the heat exchanger. On the one hand, there is a race to maximize surface area for more efficient heat dissipation, on the other, for durability and reliability. In the first case, we have boiler-type honeycomb heat exchangers, highly efficient, but problematic in cleaning and repair / replacement. On the other hand, simple tubular coils made of cold-drawn seamless pipes are difficult to argue with the classics.

5. The presence of insulation. The need for a mineral-filled housing is determined by the installation site. If it makes no sense to waste heat on the street, then for a garage or workshop an uninsulated boiler can become good method heating.

There are also differences in the type of fuel, horizontal and vertical arrangement mines, as well as the material of the furnace. The chambers and coils, made of cold rolled mild steel, are simple and unpretentious, but prone to dross formation. Cast iron coils and water-filled jackets are the most durable and not prone to scale formation, but require special piping due to their high sensitivity to thermal shock.

Equipment power

Ultimately, it is not so much the details of the boiler that are important for the boiler. internal device how many are the main performance indicators that have been achieved using a number of engineering innovations. The most important and defining parameter of the boiler is its rated instantaneous power. Specific heat at different types fuel is different, as in different breeds firewood, the manufacturer cannot predict it accurately and calculate the rated power in a particular operating mode.

Determination of power occurs according to two indicators. By the volume of the firebox, one can judge the weight of the bookmark. On average, it is believed that for every kilowatt of power of a wood-burning boiler there is 2.5-3 liters of the volume of the combustion chamber. Having received the instantaneous value of the power released during combustion, it is possible to predict how much of it can be absorbed by the heat exchanger at different temperature conditions work. Usually absorption is deliberately made higher than the calculated heat release in combustion conditions close to optimal, but this approach is fraught with trouble.

The fact is that all wood-burning boilers suffer from a common disease - the formation of tar due to high humidity burnt wood. Condensation only occurs when the temperature difference is high enough. So, the formation of build-ups on the economizer or secondary heat exchanger can stop when the heat carrier heats up to 40-45 ºС. The bottom line is that if you load the boiler by half, its power will not be enough for normal heating of the walls and heat exchangers, because of which the equipment will simply "flow".

Chimney device

The main blow from the condensation of water vapor from the wood falls on the chimney system. The length of the pipe is large, the temperature difference (especially outside) is very high. There are two approaches to solving this problem.

The first one consists in the installation of revision taps for draining condensed moisture. Such bends should be placed at the lowest point of each pivot segment, starting from the last vertical section and ending with the connection point of the boiler. The disadvantage is that the pipes for draining water periodically need to be cleaned and cannot have a significant length with a small diameter.

WITH brick chimneys or with asbestos-cement pipes no such problems arise in the cover. The difficulties of constructing such chimneys are obvious, but they can also be circumvented by using more expensive materials. We are talking about insulated sandwich pipes made of of stainless steel with mineral filler. For a chimney device today it is - the best option... To summarize: condensate does not form only in insulated chimneys.

System inertia

Another disadvantage of a solid fuel boiler is hidden in the cyclical nature of its operation and the inability to independently replenish fuel reserves. Because of this, either a high heat capacity of the house structure itself is required, or a deaf insulation, close to a passive house, or a way to store a supply of heat for the period of cooling of the system.

Since the volume of the heat exchanger itself in the boiler is small, the displacement of the system can be raised mainly by increasing the diameter of the pipes. Another alternative of this kind is the installation heat accumulator... With the right approach, it is possible to realize the accumulation of heat only after heating the main system, which will help speed up the heating of the house and solve the problem with condensation.

Underfloor heating systems have their own high inertia, which grows with the thickness of the accumulating screed. With an underfloor thermal cutoff, this can be a truly long-term source of heat. With a sufficiently thick layer, even the use of water of a higher temperature will not cause discomfort and a thermal zebra, but together with the inertia of the system, the time it takes to reach the regime increases. On the other hand, connecting a warm floor to a wood-burning boiler requires a rather complicated piping, which excludes overheating of both the boiler and the pipes in the floor.

Automation and piping of wood-fired boilers

As already mentioned, the boiler power can be controlled only by changing the amount of supplied oxygen. This system works most efficiently and accurately in mine boilers pyrolysis type on wood or briquettes.

The main automation complex includes an electronic control unit, a fan, a draft regulator with electric drive and a thermocouple tied tightly to the supply port. All these components are sold both individually and in sets for a specific boiler model. On average, all automation costs about 4-5 thousand rubles. We will separately mention the importance of having protection against falling flaps and sealing grooves on the loading and inspection hatches, chimney, draft stabilization system.

For solid fuel boilers, a number of protective devices of a different kind, installed in the hydraulic piping. Of the absolutely obligatory, it is circulation pump and protection of the furnace against overheating - safety group for reset overpressure... Please note that the outlet of the relief valve must be facing the wall or fitted with a hose to avoid injury to persons present when triggered. Safety requirements can provide for the installation of a chimney undercut valve to stabilize draft and combustion; it is mounted immediately at the outlet of the boiler or directly in front of the final vertical section.

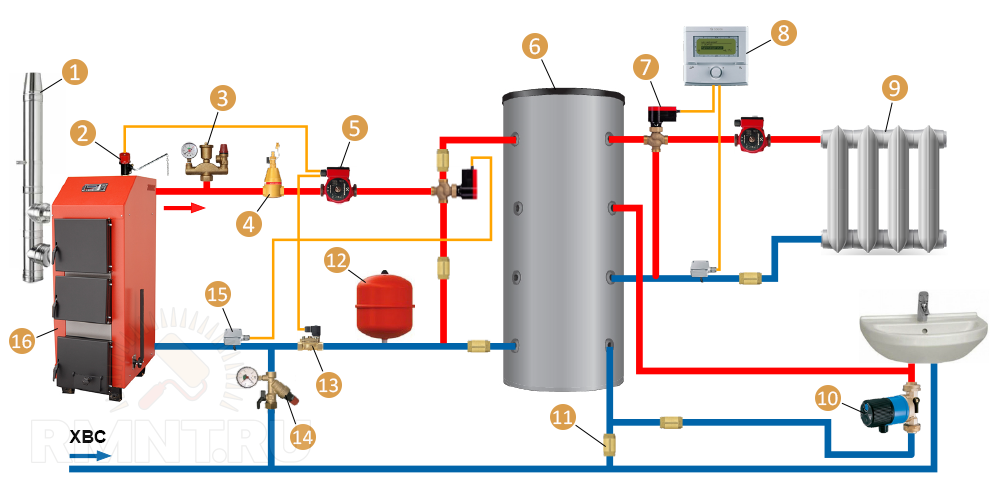

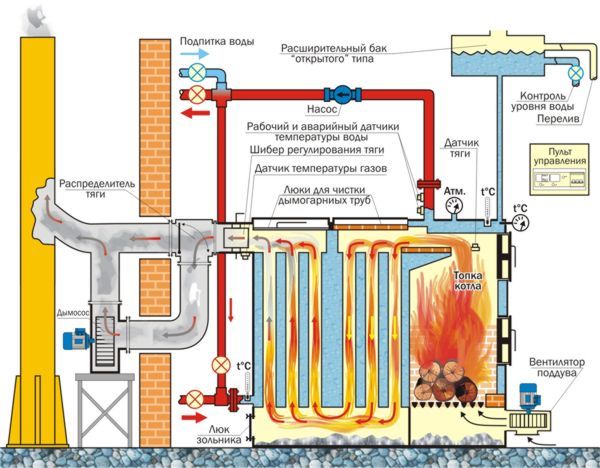

Connection diagram for a solid fuel boiler with a heat accumulator: 1 - chimney; 2 - thermostat; 3 - security group; 4 - air separator; 5 - circulation pump; 6 - heat accumulator; 7 - three-way mixer; 8 - weather-dependent automation; 9 - heating radiator; 10 - circulation pump; eleven - check valve; 12 — expansion tank; 13 - protection against dry running; 14 - make-up valve; 15 - laid-on temperature sensor; 16 - solid fuel boiler

Connection diagram for a solid fuel boiler with a heat accumulator: 1 - chimney; 2 - thermostat; 3 - security group; 4 - air separator; 5 - circulation pump; 6 - heat accumulator; 7 - three-way mixer; 8 - weather-dependent automation; 9 - heating radiator; 10 - circulation pump; eleven - check valve; 12 — expansion tank; 13 - protection against dry running; 14 - make-up valve; 15 - laid-on temperature sensor; 16 - solid fuel boiler

For cast iron boilers, it is practiced to install a two-way valve that mixes water from a hot outlet to prevent inflow cold water into a heated firebox. When installing a heat accumulator, a three-way electric valve is added, which starts the supply of heat to the tank only after the main composition has warmed up. The control is carried out according to the return temperature, the additional circuit is switched on 7-10 ºС before reaching the cut-off temperature. In this aspect, PID control units are most preferred.

Installation, connection

The boiler is installed on a concrete plinth, the height of which is determined by the balance hydraulic system... Ideally, the heating medium in the boiler should be at the highest pressure compared to the rest of the pipeline. The position of the boiler is also determined by the direction and point of connection of the flue. Its connection can be either vertical (top) or horizontal (back or side).

In the boiler piping, it is recommended to use only steel or copper pipes, the risk of overheating is too great for plastic. The section of the supply pipeline 3-5 meters from the boiler is also traditionally made with metal. Connections can be welded if there is no the necessary equipment- threaded on tow and anaerobic sealant.

The boiler should be adjusted taking into account the low heating rate and high inertia. Working temperature the coolant is maintained, as a rule, within the range of 50-65 ºС. In this case, the temperature of the reverse hysteresis should be slightly higher than the maximum, at which the boost completely stops. This is necessary so that the ignition begins long before the water in the system cools down more than expected.

1.

2.

3.

4.

The cost of heating is increasing all the time, so it is not surprising that many owners of private houses are trying to find a more economical option. One of the most popular heating devices is a long-burning wood-burning boiler. To heat rooms with it, you only need wood, and since this resource is inexpensive, you can save a lot on heating.

The gas-wood boiler is very simple and convenient to use. The only major drawback is the need to refuel it with new fuel every few hours. But new wood-burning boilers for long-term burning for home heating have special design, thanks to which one portion of firewood is enough for 12-14 hours (read also: "").

Such devices can be located in a building, in a boiler room or in a separate annex. Work heater must be monitored, therefore, the room must not be heated in the absence of a person who can monitor the boiler.

Features of wood-fired boilers

differ in design, material from which they are made, and parameters of the combustion chamber. For the manufacture of a heat exchanger for these devices, steel or cast iron is most often used. Each of these materials has advantages and disadvantages. For example, a cast-iron heat exchanger works stably and cools down for a long time, but with regular sharp changes in temperature, it can begin to collapse. Steel heat exchangers are more resistant to temperature extremes, but they are subject to corrosion and last only 10-15 years.Operational features of wood-fired boilers:

- heating of the coolant is uneven;

- carbon monoxide released during the operation of the device does not enter the chimney, but is a raw material for the production of combustible gas, which ensures environmental Safety;

- the combustion process of fuel lends itself to regulation by means of air supply;

- during burning wood material formed a large number of ash and soot;

- for the boiler to work, there must be a chimney in the room;

- it is necessary to monitor the dryness of the wood, since if it is wet, its energy qualities deteriorate;

- position and fuel must be away from different surfaces and appliances, so there should be enough free space in the room.

- high efficiency, the ability to regulate the temperature of the water supply;

- you can heat various rooms and buildings;

- the possibility of using and combining different types of fuel (read also: "");

- there is no need to connect to communications, since the heater works autonomously;

- low cost of fuel (wood).

Characteristics of wood-fired boilers

Solid propellants are single-circuit and double-circuit. The second type of boilers has a special operating principle: one circuit serves for heating, and the second provides it with hot water supply.Different appliance models have different specifications, but the average is as follows:

- power of about 100 kW;

- at the entrance to the boiler, the temperature of the coolant is at least 50 degrees;

- when leaving the boiler, the water temperature is 80 degrees;

- operating pressure- 1 atmosphere;

- the weight of the boiler is maximum 400 kilograms;

- wood, peat, coal can be used as fuel (read: "");

- the maximum length of firewood is 40 centimeters;

- The efficiency is at least 89%, this indicator varies depending on the type and moisture content of the fuel;

- the duration of work as a result of one load of firewood is about 12 hours.

Wood boilers are different increased level safety, since they are adequately protected from overheating. They can be installed in any premises, including those where it is not possible to use a gas or electric heater. In addition, these devices do not harm the environment and allow you to save on heating your home.

The principle of operation of wood-burning boilers for long burning

The operation of the device begins with smoldering fuel (wood, peat, coal) in the firebox. Since the oxygen supply is minimal, the smoldering time is significantly increased, due to which the fuel is sufficient for about 12 hours. One fill is enough for 80% longer than in a conventional boiler, which allows economical use of wood. In addition, this makes it possible to reduce the time required to monitor the operation of the device. A wood-burning boiler is suitable for a summer cottage, a private house, industrial premises- heating will be of high quality, and at the same time a lot of money will not be required for fuel.

As the smolder takes place long time, a gas with a high calorific value is generated in the bunker. It enters the combustion chamber through a refractory nozzle and ignites when exposed to oxygen. During the operation of the boiler, many heavy and hazardous compounds are burned, including soot. Thus, they do not enter the chimney. toxic substances and do not pollute environment, but burn out, giving off heat at the same time. Only non-flammable, non-toxic smoke enters the chimney.

Types and characteristics of long-burning boilers, detailed video:

Choosing a long burning boiler

When choosing any heating device, many factors must be taken into account. First of all, this concerns power, so it is necessary to calculate in advance what indicator the boiler should have in order to efficiently heat a room of a specific area. Great importance also has the efficiency of the device.Then you need to decide on the material from which the boiler should be made. Most often, steel and cast iron appliances are chosen. Weight, heating principle and device power depend on the material.

Before purchasing an appliance, you need to make sure that there is enough free space in order to locate it and store fuel supplies. The installation of a wood-fired boiler differs depending on the design and the manufacturing plant. After choosing the device, it is worth carefully examining it in order to identify them immediately if there are defects, and not during operation.

In order for the boiler to serve for a long time and work effectively, it is necessary to follow all the recommendations for operation. In addition, only dry fuel should be used, since moisture not only reduces the amount of heat generated, but also reduces the operating life of the heater.

Many owners of private houses and summer cottages are faced with the problem of organizing heating due to the lack of a gas pipeline. This leads to the need to search for other sources of energy: wood-burning boilers are used to heat the house even in the most Spartan conditions.

Wood-fired heating boilers have not lost their relevance: they have become much more perfect than their ancient counterparts, while general principles the works remain the same.

Design

The wood-fired boiler belongs to the group solid fuel devices: not only firewood can be used as a source of energy, but also peat, coal and other similar materials. The design is a device of several chambers interconnected by special nozzles. Fuel is immersed in one chamber, the other serves as a place for its transformation into thermal energy.

Roughly speaking, firewood is sent to the device, which is burned in another tank, which includes an ash pan. Here not only solid fuels are burned, but also their remains (ash) are stored. The ash pan must be periodically cleaned of waste substances: without this, the equipment will fail. The more perfect a wood-burning boiler, the less ash remains after it has been in operation. A coil-heat exchanger branches off from the boiler, which is connected to the system and hot water supply, if desired.

Scope of application

Wood-fired boilers are versatile devices that can be used in the most various industries, which makes their production profitable, and their position on the market is in demand. Wood-fired solid fuel boilers are still used in industry, but the production sector imposes more serious demands on them than the owners of private houses.

The most common area of application is the construction of private houses and cottages. It is noteworthy that wood-burning boilers operating with solid species fuel, can be used as heat sources in other buildings: for a bath, outbuildings for the farm, etc.

Dignity

Wood-fired boilers for heating have the following advantages:

- high autonomy;

- environmental friendliness and availability;

- buying fuel will not cause serious financial costs;

- many devices are automated, and therefore there is no need to constantly monitor fuel loading and system circulation.

Thus, the operation of such equipment is well within the budget and lifestyle of the average citizen.

disadvantages

The wood-fired boiler has one serious drawback - the need for storage space for fuel - a woodshed, coal extension, etc. Besides, in home option you need to periodically add firewood and it needs constant cleaning.

Principle of operation

Water heating systems often use solid fuel boilers that run on wood. The design is a diagram of three units: a firebox, a heat exchanger and a pipeline with radiators. The work is very similar to a wood-burning stove, but with the presence of a coil through which the liquid is heated.

Structure

For correct work wood-fired boilers in a system with a water circuit need the following components:

- boiler room - a complex of a pump, coil, expansion tank;

- chimney for traction and gas removal;

- pipeline, batteries and, if desired, a boiler.

It is worth noting that with the natural circulation of the water circuit, wood-fired boilers lose efficiency: condensate flows, soot often clogs. Better to give preference forced circulation with pump and bypass.

Operating principle

The principle of operation is as follows: after connecting the wood-burning boiler receives fuel, which burns and generates heat. This heat energy is absorbed by the heat exchanger and the water in the coil is heated. Due to the difference in density between cold and hot water starts up natural circulation- the coolant enters the radiators, and, being cooled, is returned for processing.

How to improve

Wood-fired boilers make it possible to connect a boiler to provide hot water supply in a private house, as well as a pump to regulate the circulation. The latter will make the system dependent on electricity, therefore, together with the pump, a bypass must be installed - a forced circulation switch to natural. The water circuit in the heating system, which includes a wood-fired boiler with a pump, heats the room 2 times more efficiently.

Classification by type of feed

Depending on the type of supply, the wood-fired boiler can be manually loaded and with automatic feeding fuel. Manual loading implies long burning - such devices can operate on wood for about 70 hours with air supply through a special telescopic system. This simple and robust design able to heat the area of a private house of 20-600 m2, with a capacity of 7 to 40 kW.

Pyrolysis oven.

A less popular and less expensive type is wood gas pyrolysis stoves, which is obtained by burning wood at high temperatures. Such a system is good in that it leaves a minimum of ash, but firewood is enough for 10 hours.

Finally, pellet stoves with automatic feeding operate on a special type of fuel - pellet, which is processed and compressed waste from the woodworking industry. Firewood and coal can be used if desired. Such wood-fired boilers are used for huge rooms from 150 m2 and above.

Gasification of our country began a long time ago. And nevertheless, we still have a lot of settlements where gas mains have not yet reached. As a result, residents are forced to look for alternative sources heat. They are wood-burning boilers that run on the cheapest fuel - wood. And if you can get firewood completely free of charge, then the heat will become as cheap as possible, since you will only need to spend money on the boiler, pipes and batteries. In this review, we will study the main types of solid fuel equipment and consider its features.

The principle of operation and features of wood-burning boilers

In the absence of a gas main, we can choose the following equipment for heating houses:

- Electric boilers - are distinguished by their low cost, but consume a huge amount of electricity;

- Liquid boilers - heat is obtained cheaper, but consumers are forced to store fuel somewhere;

- Wood-fired boilers are the most economical, and in some cases the most cheap way heating.

Wood-fired boilers for home heating are a smart alternative to other heat sources. This is relevant in countryside, where there is a low level of income of the population.

An important disadvantage of liquid equipment is that the smell of diesel fuel or used oil spreads throughout the house, and it is very difficult to weather all this.

Design features

A wood-fired boiler, unlike its gas and electric counterparts, is a fairly simple and straightforward unit. This reduces the likelihood of breakage and simplifies possible future repairs.

Wood-burning boilers are extremely simple, because they descended from ordinary stoves. Manufacturers, on the other hand, had several problems to solve - to make the equipment more convenient to use and more efficient. All these tasks are quite solvable, therefore modern heating boilers on the wood are different high efficiency and ease of use. The most difficult thing in them is to kindle a flame, after which all that remains is to periodically toss firewood.

The wood-fired solid fuel boiler is distinguished by the most simple device... Its heart is a combustion chamber in which logs are burned. The resulting heat passes through the heat exchanger, and its residues are removed through the chimney. Heat exchangers in such units are most often performed according to a fire-tube scheme - this allows them to withstand a large thermal load. Solid residues of wood fall through grate into the ash pan.

Ash pan - very an important part wood boiler. It is here that unburned fuel particles, small coals and ash are collected. Once every few days, the ash pan must be cleaned, as it quickly clogs up. Wood-fired boilers with drawers for ash - they are more convenient to use. By the way, ash does not have to be scrapped, because it is safe. organic fertilizer... If you have a plot with a vegetable garden, you can use the ash to feed crops.

How wood-fired boilers work

The principle of operation of wood-fired boilers is very simple:

The significant disadvantages of wood-burning boilers should be attributed high consumption fuel and actually the impressive dimensions of the required supply of this very fuel. Ideally, you will have to allocate a whole room for this.

- Burning wood gives off heat, which is absorbed by the heat exchanger;

- The coolant flowing through the heat exchanger is sent to the radiators that heat the premises;

- The coolant is sent back to the boiler, where it is heated again.

Here we see the most common convection heating scheme that is used in traditional gas units.

It is profitable to heat households with wood-burning boilers - the cost of firewood is quite low, the costs for one season will be only 10-15 thousand rubles when heating a house for 100-150 sq. m. It is even cheaper than heating with gas. The calorific value of wood fuel is high, so a lot of heat is generated during combustion. Unfortunately, some of it flies into the chimney, but this problem is solved with the help of pyrolysis wood-burning boilers - we will consider them in the next section of our review.

Varieties of wood-fired boilers

Solid fuel boilers for heating a private house in most cases are classic convection units... In them, firewood is burned directly, with the formation of a powerful flame, the heat from which is immediately taken by the heat exchanger. Disadvantages of this scheme:

- Lack of possibility of smooth temperature control;

- Not the highest efficiency;

- Virtually no automation.

With the help of traditional wood-burning boilers, it is difficult to maintain a certain temperature - the intensity of combustion, if regulated, is within extremely small limits.

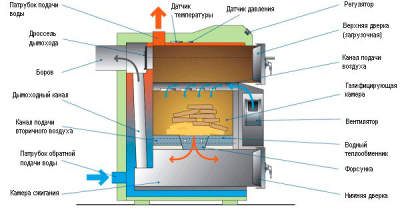

Pyrolysis wood-fired boilers are an alternative to convection appliances. They are built according to the gas generator scheme. Firewood is burned here in an oxygen-poor atmosphere. In fact, they do not burn, but simply smolder. Due to the high temperature, they begin to release pyrolysis products that are flammable. The combustible gases are burned in a separate chamber (called the afterburner), where secondary air is fed. And in order to be able to adjust the intensity of combustion, the equipment is equipped with blowing fans.

Wood-burning boilers, built according to the pyrolysis type, are more complex than their convection comrades. Here we see two chambers - in one, firewood is smoldering, emitting pyrolysis gases, and in the second, these gases burn out at a very high temperature reaching + 800-1000 degrees. The released heat is absorbed by the same fire-tube heat exchanger and partially by a protective water jacket (if any).

Pyrolysis wood-fired boilers are endowed with automation systems that control blowing fans. As soon as the temperature is in heating system reaches the set limit with the batteries, the fan stops, the flame in the afterburner goes out. This happens until the temperature in the heating system drops - then the blowing fan starts up, and a humming flame appears in the afterburner.

Pyrolysis gas-fired wood-fired boilers need dry wood. Using raw logs, pyrolysis will be difficult or impossible. The efficiency of this equipment reaches 90%, as the calorific value of solid fuel increases.

Advantages and disadvantages of wood-fired boilers

A wood-fired heating boiler is great alternative other types heating equipment... It is expensive to heat with electricity, heating with diesel fuel or working off is also not without its disadvantages (although there are advantages). Therefore, a wood-burning boiler should be chosen as the cheapest option for organizing heating. We install it in the boiler room, install pipes around the house, install radiators, throw firewood into the firebox and enjoy the warmth.

Let's now see if everything is so good with wood-burning boilers. And we will start by describing their advantages, against the background of which disadvantages will dazzle. Main positive features:

Firewood - pretty cheap look fuel, but quite whimsical. Only logs that are very dry and not eaten by beetles can give a good and high-quality heat.

- Cheapness of heating - it comes that fuel for wood-burning boilers is quite inexpensive. And if possible, you can collect it for free in the nearest forest - in order not to have problems with the law, pay attention to the fallen trees, which will be an excellent source of firewood;

- No need for permission to install equipment - the same gas boilers you need to connect to the highway, register them with the controlling services, pay for annual maintenance. In other words, there is a lot of trouble;

- Easy to operate - you just need to kindle the flame, and then the process will go on its own. You just have to remember to throw all new portions into the insatiable firebox of the wood-burning boiler;

- Safety - as opposed to gas or electrical equipment, wood-fired boilers are characterized by increased safety.

There are also disadvantages:

- The wood-burning boiler needs constant supervision - you need to control the temperature in the circuit and put firewood. Fast burning of firewood is a key drawback, but is eliminated by choosing a boiler with a large combustion chamber (or pyrolysis unit);

- Expensive equipment - a good wood-fired boiler made of cast iron, resistant to corrosion and heat loads, will be expensive. Alternatively, you can consider cheaper steel units, but they do not differ in reliability and long service life;

- To store firewood, you will have to build a woodpile - it will take up a lot of space;

- Difficulty in automation - the problem is solved by using pyrolysis wood-fired boilers with large combustion chambers and systems for adjusting the intensity of combustion;

- There is a peculiar smell of haze in the rooms - it cannot be said that it is unpleasant, but some people do not like it;

- The need for a separate ventilated room under the boiler room - you cannot put it in a common room;

- Bulky - for small houses you can find wood-burning boilers in mini format, but for the most part they have large size... And they are mounted only on the floor, while separate gas and electrical units neatly positioned on the walls without taking up extra space.

Thus, wood-burning boilers also have negative traits.

In order to ensure complete safety when using a wood-burning boiler, it is necessary to install it on a sheet of non-combustible material.

Features of wood heating

The ash pan and chimney should be cleaned at on a regular basis... This will allow the boiler to serve you faithfully. long years, do not lose my effectiveness.

If you plan to use a wood-fired heating boiler in your home, you will need information on some of the features of wood heating. First of all, you will need reliable supplier firewood. Moreover, the fuel must be prepared before the onset heating season... In some regions, firewood is in short supply and is significantly more expensive than in others.

Secondly, you will have to come to terms with the fact that you will need to become a real nanny for a wood-burning boiler - you need to monitor the temperature in the heating system, avoiding overheating, bring new portions of firewood, throw logs into the firebox, make sure that in the chamber combustion did not extinguish the flame. If you don’t buy a long-burning boiler, you will have to get up even at night so as not to clap your teeth in the morning.

You will also need to monitor the chimney, especially if it is a narrow metal pipe- due to the accumulation of soot, the thrust decreases, and in some cases it can lead to an explosion (fortunately, this is a rare phenomenon). And the requirements for chimneys make you think - the more the power of the wood-burning boiler used, the higher the pipe should be, otherwise there will be insufficient draft.

Popular factory models

If you are planning to buy a wood-fired heating boiler, we recommend that you pay attention to the most popular models. Let's consider them in more detail and touch on the estimated prices.

This wood burning boiler has received the most positive user reviews. It is distinguished by its simplicity and versatility - it provides electric heater, responsible for maintaining the temperature when the wood is completely burned out, and users have missed the moment when it was necessary to throw a new portion of fuel into the firebox. However, the heating element may not be used.

The thermal power of the wood-burning boiler is 15 kW, which is enough to heat households with an area of up to 150 sq. m. The efficiency of the device is not very high, it is 75%. Ordinary firewood or coal is used as fuel; it is also allowed to use eurowood. The coolant temperature in the system varies from +60 to +85 degrees, the maximum pressure is 2 bar. The heat exchanger is made of steel and supplemented with a 4 kW heating element. The unit weighs 115 kg. Estimated price- within 17-19 thousand rubles.

Before us is a powerful wood-burning boiler from renowned manufacturer, which has proven itself with the best side... The power of the unit is 19 kW, the heated area is up to 190 sq. m, the temperature of the coolant can be regulated from +30 to +85 degrees, despite the fact that the scheme of direct combustion of firewood is used here. The efficiency is 90.2% - this is very high rate providing economical fuel consumption. An indisputable advantage is the use of a two-way multi-section cast iron heat exchanger. To control the parameters, there is a pressure gauge and a thermometer on board. Estimated price - about 45 thousand rubles.

Finally, consider a mechanically controlled pyrolysis wood-burning boiler - models with electronics are much more expensive. The unit has a capacity of 12 kW and can heat buildings up to 120 sq. m. At the same time, he is omnivorous - he knows how to work on wood, briquettes, coal, peat and pellets. Its efficiency is 92%, Maximum temperature coolant - up to +95 degrees with the possibility of adjustment due to the blower. The cost varies between 54-60 thousand rubles, depending on the appetite of the store.

Video "Wood-fired boilers for heating private houses"